Feeder design and diet management impact performance with DDGS diets

Part 10 in the series “What have we learned about feeding distillers co-products to pigs over the past 20 years?”

March 4, 2019

By Jerry Shurson, University of Minnesota Department of Animal Science

Achieving optimal nutrition requires more than accuracy and precision in diet formulation. Feeder design, space, diet form and feeding management are also important factors in precision swine nutrition programs. Several studies have evaluated the influence of these factors when feeding distiller’s dried grains with solubles diets to pigs.

Feeder design

There are a many commercial feeder designs used in commercial swine operations that have various advantages and disadvantages. Bergstrom et al. (2012) conducted three experiments to evaluate using conventional dry feeders compared with wet-dry feeders and various feeder adjustment openings on growth performance and carcass characteristics of growing pigs fed corn-soybean meal diets containing 15% DDGS diets (Experiments 1 and 2) and corn-soybean meal diets containing 25% DDGS and 20% bakery byproduct.

Results from this study showed that pigs fed using the wet-dry feeders had greater average daily gain, average daily feed intake, hot carcass weight and carcass backfat thickness than pigs fed diets using dry feeders. However, successive decreases in feeder openings of wet-dry feeders can provide similar final body weight compared with using a constant opening, but feed intake was reduced and carcass characteristics improved. They concluded that using successive decreases in feeder openings of wet-dry feeders may be effective for minimizing increasing backfat thickness without reducing growth rate because wet-dry feeders appear to be more sensitive to differences in feeder adjustments compared with conventional dry feeders.

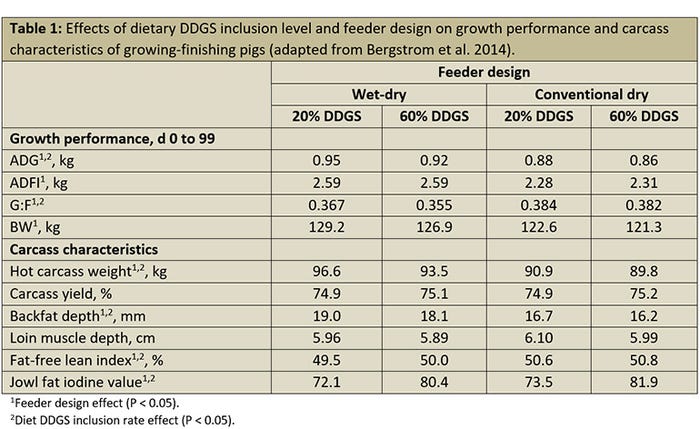

In a subsequent study, Bergstrom et al. (2014) conducted three experiments to compare growth performance and carcass characteristics of growing-finishing pigs fed diets containing DDGS diets using wet-dry or conventional dry feeders on a commercial farm. Diets in Experiment 1 contained 9% DDGS in Phase 1 and 20% DDGS in Phases 2, 3 and 4. Diets fed in Experiment 2 contained 9, 20, 30, 30 and 17% DDGS in Phases 1 to 5 respectively, whereas in diets containing 20% or 60% DDGS where fed in Experiment 3. Diets were formulated on a metabolizable energy basis using a value of 3,420 kilocalories per kilogram for DDGS that contained greater than 10% oil. Standardized ileal digestibility values of amino acids in DDGS were obtained from Stein et al. (2006) and used in diet formulation. The ME and SID amino acid values for all other ingredients were obtained from National Research Council (1998).

Installments in the DDGS series

Part 1: 20 years of DDGS lessons in pig diets

Part 2: Varied energy and digestible amino acids levels in DDGS manageable

Part 3: Work continues to evaluate performance responses from feeding DDGS

Part 4: Managing carcass yield, pork fat quality when feeding corn DDGS

Part 5: Reaching an understanding of fiber characteristics of corn DDGS

Part 6: Enzymes, pre-treatment improve fiber and nutrient digestibility

Part 7: DDGS show greater antioxidant capacity than in corn grain

Part 8: Need better understanding of energy levels in distillers corn oil

Part 9: Corn DDGS a good source of digestible phosphorus for swine

Part 10: Feeder design and diet management impact performance with DDGS diets

In all experiments, pigs fed using the wet-dry feeders had increased ADG, ADFI and final body weight compared with using dry feeders. Gain:feed tended to be, or was improved for pigs fed using the conventional dry feeders. In Experiments 2 and 3, pigs fed using wet-dry feeders had heavier hot carcass weight, greater carcass backfat depth, less carcass fat-free lean and lower jowl fat iodine value than pigs fed using the conventional dry feeders. Feeding the 60% DDGS diets reduced ADG, G:F and tended to reduce final body weight compared with feeding the 20% DDGS diets (Table 1). Furthermore, feeding 60% DDGS diets resulted in reduced hot carcass weight and backfat depth, tended to increase carcass fat-free lean percentage and increased jowl fat iodine value, but had no effect on carcass yield regardless of feeder type.

These results suggest that using wet-dry feeders improves ADG and ADFI, but reduces G:F and increases carcass fat compared with using conventional dry feeders. There appear to be no feeder design × DDGS inclusion rate interactions for growth performance and carcass measurements. However, high diet inclusion rates (60%) of DDGS may reduce ADG, gain efficiency, hot carcass weight and backfat thickness, but increase the percentage of carcass fat-free lean percentage and jowl fat iodine value compared with feeding diets containing 20% DDGS to growing-finishing pigs.

Feeder space

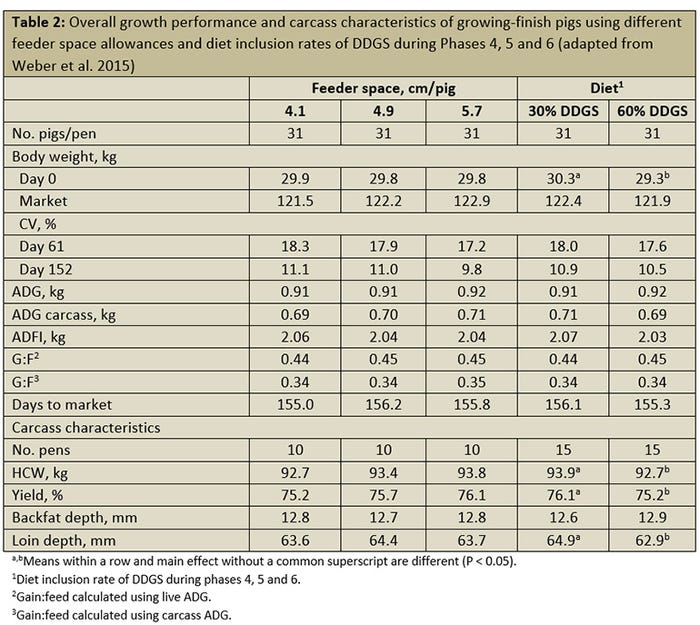

In addition to feeder design, feeder space allowance can also affect growth performance of growing-finishing pigs. Weber et al. (2015) conducted a study to evaluate growth performance of pigs fed 30 or 60% DDGS diets using different feeder space allowances. The metabolizable energy content of DDGS was estimated using the equation from Noblet and Perez (1993), and varying amounts of choice white grease were added to achieve isocaloric diets among treatments. A five-phase late-nursery and growing-finishing feeding program was used, with dietary DDGS inclusion rates of 27.5%, 30.0%, 32.5%, 32.5% and 26.3% in Phase 3, 4, 5, 6 and 7, respectively.

Dietary inclusion rates of DDGS for the 60% DDGS treatment were 30.0%, 59.9%, 59.9%, 59.9% and 30.0% in Phase 3, 4, 5, 6 and 7, respectively. There were no interactions between feeder space allowance and DDGS inclusion rate, which indicates that feeder space allowance does not affect growth performance and carcass characteristics of pigs fed 30% or 60% DDGS diets during the growing-finishing period. Furthermore, there were no differences in final body weight, ADG, ADFI and G:F of pigs fed the 30% or 60% DDGS diets (Table 2). However, pigs fed the 30% DDGS diets had slightly heavier hot carcass weight and greater carcass yield and loin depth at slaughter compared with pigs fed the 60% DDGS diets. These results suggest that the different feeder space allowances provided during the growing-finishing phase had no effect on growth performance or carcass characteristics of pigs fed 30 or 60% DDGS diets, but feeding the 60% DDGS diets slightly reduced hot carcass weight, yield and loin depth compared with pigs fed 30% DDGS diets.

Feeder design and diet form

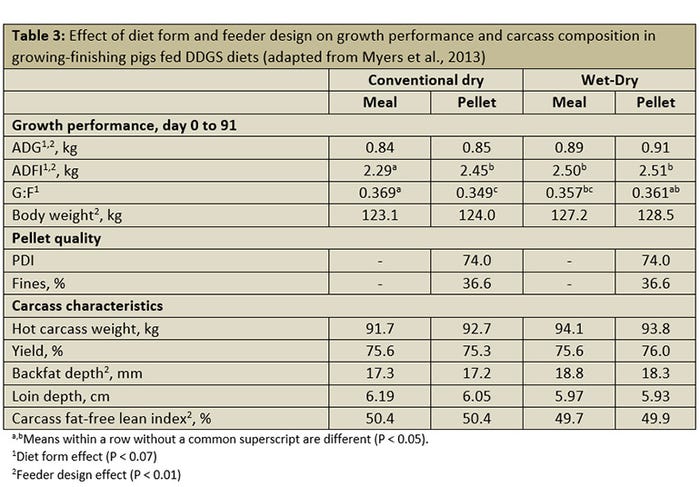

It is well known that feeding pelleted diets to pigs generally improves feed conversion, but achieving optimal pellet quality (pellet durability index) is a challenge when manufacturing pelleted DDGS diets because of its low starch and high fiber content. Myers et al. (2013) fed meal or pelleted diets containing 25% to 45% DDGS to evaluate diet form and feeder design (conventional dry or wet-dry feeders) on growth performance and carcass characteristics of growing-finishing pigs (n=1,290) using a five-phase feeding program. The PDI of the pelleted DDGS diets was less than optimal, and resulted in about 37% fines in the experimental diets. There was no diet form × feeder design interaction for ADG, but pigs fed pelleted diets had greater ADG than those fed meal diets (Table 3). Similar to the results reported by Bergstrom et al. (2014), pigs fed using the wet-dry feeders had greater ADG compared with those fed with conventional dry feeders.

Feeding meal diets in dry feeders resulted in reduced ADFI compared with pigs fed pelleted diets, but ADFI was not different between the two diet forms when using wet-dry feeders. Gain:feed was similar for pigs fed meal or pelleted diets using wet-dry feeders, but was reduced when pigs were fed pelleted diets using the dry feeders compared with pigs fed meal diets. There were no diet form × feeder design interactions, nor differences between diet forms for any carcass characteristics. However, pigs fed with the wet-dry feeders had more backfat and a lower percentage of carcass fat-free lean than pigs fed using dry feeders.

These results, suggest that although optimal pellet durability was not achieved in this study, feeding pelleted DDGS diets using wet-dry feeders appears to optimize growth performance but may reduce the percentage of carcass fat-free lean.

Feeding management

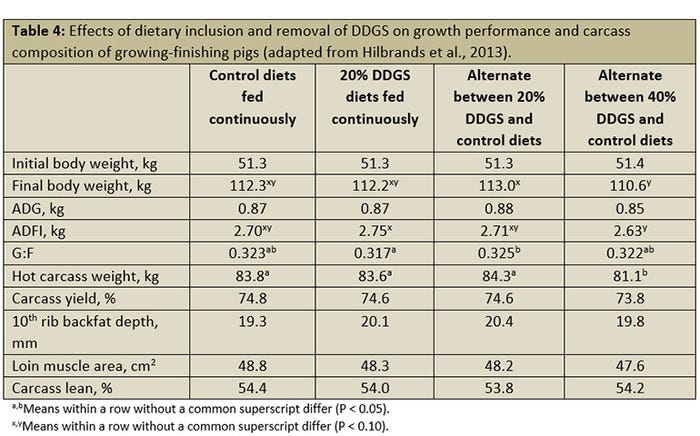

At certain times during the year, fluctuations in DDGS price and availability may result in intermittent use in swine diets in order to maximize economic returns over feed costs. To evaluate this scenario, Hilbrands et al. (2013) conducted an experiment to determine the effects of alternating diets with and without DDGS during the growing-finishing phase on growth performance and carcass characteristics using a three-phase feeding program consisting of corn-soybean meal control diets, or 20% or 40% DDGS diets fed continuously, or alternating between control and 20% DDGS diets or control and 40% DDGS diets every two weeks.

There were no differences in ADG, carcass yield, backfat thickness, loin muscle area or carcass lean percentage among dietary treatments (Table 4). Pigs fed the 20% DDGS diets continuously tended to have greater feed intake than pigs fed alternating 40% DDGS and control diets every two weeks. Furthermore, alternating between the control and 20% diets resulted in greater gain efficiency than pigs fed the 20% DDGS diets continuously. Hot carcass weight was reduced when alternating between control and 40% DDGS diets compared with other dietary treatments but there were no effects of dietary treatment on other carcass traits. These results suggest that alternating between corn-soybean meal diets and 20% or 40% DDGS diets every two weeks has minimal effects on growth performance and carcass characteristics.

Many commercial feed mills use multiple sources of DDGS with variable nutrient content and digestibility, which may influence growth performance and carcass composition if appropriate adjustments in energy and digestible amino acid content are not made when formulating diets.

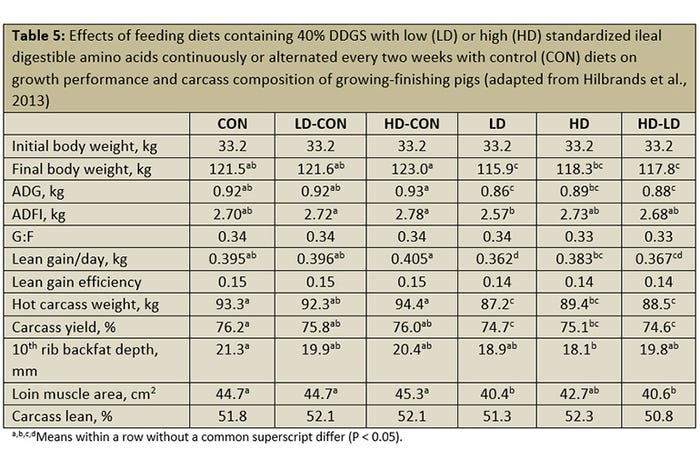

In a second experiment, Hilbrands et al. (2013) obtained two sources of DDGS with low or high SID amino acid digestibility. Metabolizable energy content of these sources was estimated using ME prediction equations from Pedersen et al. (2007). The SID amino acid values from these DDGS sources were derived from the IDEA assay (Novus International, St. Louis, Mo.). Values for ME and SID amino acid content for corn and soybean meal were obtained from NRC (1998). All diets (corn-soybean meal control, 40% DDGS with low-digestible amino acids and 40% DDGS with high-digestible amino acids were formulated on an SID amino acid basis and fed in four-phases. Six dietary treatments were fed consisting of: 1) CON diets fed continuously, 2) LD diets fed continuously, 3) HD diets fed continuously, 4) LD and CON diets alternated by phase, 5) HD and LD diets alternated by phase, and 6) HD and LD diets alternated by phase. Pigs fed LD and HD-LD had reduced ADG and lower final body weight compared with CON, and feeding LD resulted in lower ADFI than LD-CON and HD-CON, but G:F was not affected by dietary treatment (Table 5).

These results indicate that the SID amino acid content was likely overestimated by the IDEA assay when formulating diets. Pigs fed LD and HD-LD had reduced hot carcass weight, yield and loin muscle area than the other dietary treatments. However, periodic inclusion and removal of 40% DDGS from diets did not adversely affect overall growth performance regardless of amino acid digestibility of the DDGS source fed. Furthermore, there were no differences in the percentage carcass lean among dietary treatments. Therefore, the results of these two experiments indicate that alternating between corn-soybean meal and DDGS diets every two weeks has minimal effects on growth performance or carcass composition.

Conclusions

Feeding DDGS diets to growing-finishing pigs using wet-dry feeders appears to result in improved ADG and ADFI, but not gain efficiency, compared to using conventional dry feeders. However, increased carcass backfat and reduced carcass fat-free lean percentage may occur when feeding DDGS diets using wet-dry feeders. Providing feeder space allowances between 4.1 to 5.7 cm per pig during the growing-finishing phase does not affect growth performance or carcass characteristics of pigs fed 30% or 60% DDGS diets. Achieving optimal pellet durability when pelleting DDGS diets can be a challenge. However, feeding pelleted DDGS diets using wet-dry feeders appears to optimize growth performance compared with using conventional dry feeders, but may result in reduced percentage of carcass fat-free lean.

Finally, alternating between corn-soybean meal and 20% to 40% DDGS diets every two weeks has minimal effects on growth performance or carcass composition of growing finishing pigs.

References

Bergstrom, J.R., J.L. Nelssen, M.D. Tokach, S.S. Dritz, R.D. Goodband, and J.M. DeRouchey. 2012. Effects of two feeder designs and adjustment strategies on the growth performance and carcass characteristics of growing-finishing pigs. J. Anim. Sci. 90:4555-4566.

Bergstrom, J.R., J.L. Nelssen, M.D. Tokach, S.S. Dritz, R.D. Goodband, and J.M. DeRouchey. 2014. The effects of feeder design and dietary dried distillers’ grains with solubles on the performance and carcass characteristics of finishing pigs. J. Anim. Sci. 92:3591-3597.

Hilbrands, A. M., L. J. Johnston, K. M. McClelland, R. B. Cox, S. K. Baidoo, L. W. O. Souza, and G. C. Shurson. 2013. Effects of abrupt introduction and removal of high and low digestibility corn distillers dried grains with solubles from the diet on growth performance and carcass characteristics of growing-finishing pigs. J. Anim. Sci. 91:248-258.

Myers, A.J., R.D. Goodband, M.D. Tokach, S.S. Dritz, J.M. DeRouchey, and J.L. Nelssen. 2013. The effects of diet form and feeder design on the growth performance of finishing pigs. J. Anim. Sci. 91:3420-3428.

Noblet, J., and J. M. Pérez. 1993. Prediction of digestibility of nutrients and energy value of pig diets from chemical analysis. J. Anim. Sci. 71:3389–3398.

NRC. 1998. Nutrient Requirements of Swine. 10th ed. National Academy Press, Washington, D.C.

Pedersen, C., M. G. Boersma, and H. H. Stein. 2007. Digestibility of energy and phosphorus in ten samples of distillers dried grains with solubles fed to growing pigs. J. Anim. Sci. 85:1168–1176.

Stein, H. H., M. L. Gibson, C. Pedersen, and M. G. Boersma. 2006. Amino acid and energy digestibility in ten samples of distillers dried grain with solubles by growing pigs. J. Anim. Sci. 84:853–860.

Weber, E.K., K.J. Stalder, and J.F. Patience. 2015. Wean-to-finish feeder space availability effects on nursery and finishing pig performance and total tract digestibility in a commercial setting when feeding dried distillers grains with solubles. J. Anim. Sci. 93:1905-1915.

Source: Jerry Shurson with the University of Minnesota, who is solely responsible for the information provided, and wholly owns the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like