’19 Pork Masters: The Maschhoffs’ man behind the scenes

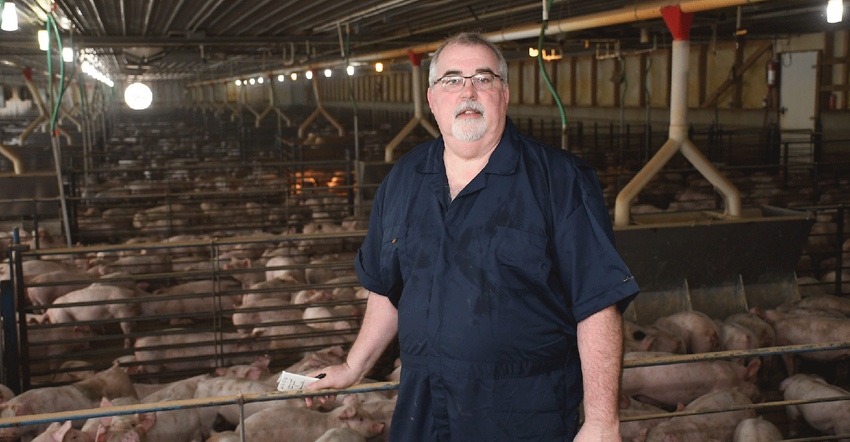

Quick puts pigs, people first, always helps others.

There may be an “I” in Steve Quick’s name, but the word is uncommon in the vocabulary of The Maschhoffs’ senior consultant.

During his 40-year career with the organization, he has stood shoulder to shoulder with the family as they built the business from a 750-sow operation in southern Illinois to the 204,000-sow empire across the Midwest it is today. All along the way, Quick’s commitment to the business, his team members and most importantly, the pigs, has never wavered.

“A lot of times my role is just to give people confidence in their own ability,” Quick says. “It’s not like I’m doing anything special. I’m just kind of giving them the power back and saying, ‘You know what you need to do, and you can do it.’ ”

Quick may not be well-known across the broader U.S. pork industry, but he’s a legend in The Maschhoffs organization. His past and present colleagues fondly refer to him as a teacher, a coach, an advocate and a stockman who can trouble-shoot and solve any pig-related issue. A true ambassador, who never says a cross word and always smiles, Quick has performed nearly every function of hog production over the course of his career, including sows, wean to market, boar studs, logistics, marketing and health.

He is the go-to person at The Maschhoffs.

“Should he be named a Master, he’ll be honored beyond belief — and in typical farmer style, will instantly downplay his own actions, pushing the credit toward those of us who have had the pleasure to work with him,” writes Clayton Johnson, Carthage Veterinary Service, in his nomination letter.

Johnson, who had the privilege to work with Quick for eight years, says “Steve is the epitome of the pig farmer I describe to people on an airplane when I tell them I work in pig production — he does what’s right for his animals and employees every day without fail. Steve works tirelessly and selflessly; he’s the definition of a servant-leader, putting the well-being of every person and pig in the barn above himself.”

For these reasons and many more, Quick has been selected as a member of the 2019 Masters of the Pork Industry class.

The husbandry gene

His instinctive way of caring for pigs may seem like second nature to many of his colleagues, but it’s something Quick says he observed as a young boy on his family’s small, diversified 80-acre farm in southern Illinois. One of his favorite childhood memories growing up was taking his father coffee in the middle of the night as he toweled down a fresh litter, then placing the piglets under a heat lamp to keep them warm.

“My father was one of the hardest-working men I’ve ever been around, calm and even-keeled to be around, a kind man and enjoyed family,” Quick says of his dad, who also worked full time off-farm in construction to provide for the family. “I think a lot of my basic behavior comes from him, and my work ethic, too.”

Quick jokes he was probably a “country hick” growing up, but he always felt comfortable in an agricultural setting and around livestock. In high school, a teacher even had him leaning toward a career in agricultural education. But it wasn’t until the 17-year-old took a job just 18 miles down the road from where he grew up that he knew he wanted to be involved in pork production.

“I had been working for my uncle cultivating beans, and a friend of mind had started working here,” Quick says. “The Maschhoff family was building the first big expansion to the home complex — a 650 farrow-to-finish confinement barn.”

The farm belonged to Wayne and Marlene Maschhoff of Carlyle, Ill. Quick had gone to high school with their sons, Ken and Dave, but didn’t really know them very well. However, he was eager to join the construction crew, and he was soon driving wedges and slinging concrete forms every weekend, holiday and summer break from Southern Illinois University.

Job before the title

Construction was how Quick got his foot in the door, but he admits every now and then he would slip over to do some pig work. After he graduated with an animal science degree, the newly constructed barn was up and running, and Quick knew it was where he was meant to be.

“I knew I had a job if I came back. After the first summer, I had hit it off with the boys and Wayne and Marlene. I have been very fortunate to work for people who I consider family, and I always have,” Quick says. “We had similar work ethics. We [myself and the boys] might have had a mischievous streak, but we got along fantastic, and I was earning money and working with friends and enjoying myself. It was just a great scenario to be in.”

It was 1983 when Quick came on board full time with The Maschhoffs. There were three or four others working at the new site with 600 sow units, and the farm had other expansions in the works. Quick found himself gravitating to the hog house, though. Looking back, he says he probably assumed the role of production manager.

“Maybe it was my nature, and I migrated to it, but eventually one of my friends in the barn said, ‘Why don’t you become general manager? You’re doing the job anyhow,’ ” Quick says. “I wasn’t really looking for the title, but it put me in an official position and a direction for me. I approached Ken and Dave with that concept, and they agreed — and it’s kind of been that role ever since.”

Quick says Ken and Dave also gave him autonomy with the position and a shared responsibility in the farm, allowing him to take on an indirect ownership of the herd.

“After 40 years, I’ve always referred to them as my hogs, and they were comfortable with that and never hindered that mindset,” Quick says.

While Quick went on to hold the title of production manager for the next 20 to 25 years, his responsibilities kept expanding and growing in The Maschhoffs’ organization.

Initially, production expansions were local and involved converting systems from finishers to gestation, nurseries to farrowing and wean to market, to break up production stages for health benefits. After they filled their footprint locally, The Maschhoffs began to look outside their region to add contract finishers.

“We always had people in positions behind us during those early years that were ready to take on more responsibility, so that allowed us to grow and me to expand out,” Quick says. “Without those people in place and ready to step up, I would never have been able to step out and take on contract finishing relationships. We always had a good workforce and people ready to assume that next role.”

Show and tell

As the company expanded, Quick spent more time in the field helping contract partners get established. Some were new to raising livestock. Quick would help those growers get started and walk them through the ventilation and the production practices, before bringing on field staff to help support the needs out in the finishers.

For the most part, the expansions went smoothly. Quick credits the production partners they selected and admits he learned from some of the more experienced growers along the way.

However, those who have worked with him say he has always been the fundamental part in successfully onboarding new partners within the organization.

Scott W. Stehlik, general manager, technical operations, The Maschhoffs, has worked with Quick for the past seven years. He has seen firsthand the passion Quick exhibits when he is helping new and inexperienced employees and caretakers learn the fundamentals of animal husbandry and management.

“He enjoys seeing people become equipped and capable of figuring out solutions to the problems they find in the barn,” Stehlik says. “And he is willing to roll up his sleeves and work side by side if that’s what it will take to get the job done.”

Onboarding with ease

In 2005, The Maschhoffs doubled in size when it acquired the Land O’Lakes pork production system. Quick admits there was apprehension going forward, but he says once he met the Land O’Lakes people on staff, he knew the transition would be smooth.

“Their production folks were very talented and that was a big reason we were willing to take on that big of a risk or jump,” Quick says. “It was challenging, but it was fun and exciting rolled up into one at the same time.”

With the Land O’Lakes acquisition, The Maschhoffs production jumped up to more than 100,000 sows and spread the system geographically across Illinois, Iowa, Missouri and Oklahoma.

“It really changed our footprint dramatically. I think one of the biggest advantages is that our company is really built on pig people, and we really enjoy being out with the animals — from our president, Bradley Wolter, on down to our management. I think that helped us connect through these purchases,” Quick says. “We would get out on the farms with people. We would go grab the squealing pig in the farrowing crate and give it a hug, out of habit. That production bond helped us gain acceptance.”

Acquisitions continued for The Maschhoffs, first in 2008 with the Blackjack Pork assets, and then in 2011 with the NPP System, bringing the company to its current size of more than 200,000 sows and a nine-state footprint. Quick says just like the Land O’Lakes staff, these acquisitions also brought along a talented group of production personnel.

“Our task then was to integrate their skill into The Maschhoffs’ livestock production philosophy,” Quick says. “Like Land O’Lakes, these groups also brought new ideas that we could benefit from and incorporate into the ‘global’ TML [The Maschhoffs livestock] production strategy.”

Paul Ayers, animal care manager for The Maschhoffs, points to the best-selling book “Good to Great” to describe Quick’s leadership on the team, and getting these acquisitions on board. In the book, author Jim Collins analyzes the qualities of leaders who propel their organizations from average to exceptional, saying these leaders often compel modesty, are self-effacing and often talk less about themselves than about others on the team.

“They do not always motivate by giving rousing speeches, but have an intense passion for the organization’s purpose and display unwavering resolve to produce results that make the company great. According to Collins, many of these leaders are more ‘plow horse’ than ‘show horse,’ ” Ayers says. “Steve Quick is a true ‘plow horse’ and has consistently driven for results that have led to the growth and success of The Maschhoffs.”

Job unfinished? No quitting

“Stockman” is the word Randy Bowman, director of technical services, The Maschhoffs, says describes Quick best.

“He’s a dying breed that doesn’t understand there is a ‘starting time’ or a ‘quitting time,’ ” Bowman says. “When you get a farm visit report from Steve, you can read the passion between the lines.”

For example, Bowman recalls a time when he and Quick were hauling pigs to Iowa during a snowstorm.

“Steve watches everything like a hawk; and while we were talking, he noticed that a truck was scheduled to load more pigs than he thought it could carry in the current weather we were having,” Bowman says. “He called the transport lead and asked if that particular truck could hold that many pigs, and the response was ‘I think so.’ Steve responded back, ‘ “I think so” kills pigs.’ The load size was reduced.”

High standards

Quick shrugs it off as just his mindset. For example, a year ago, he was working with the production manager at a farm, and they couldn’t find the replacement igniter for a heater that was out. One barn was getting cold, and the temperature was dipping below The Maschhoffs’ desired temperature range. They could not locate an igniter for this particular brand of heater and could not get it repaired immediately.

Quick and the production manager propped up the barn as best as they could, attempting to compensate with the second room heater, and hit the road. As he drove away, though, Quick couldn’t stop thinking about the situation — and then he heard the weather forecast.

He knew he had to go back, so he called the production manager who was also already 15 miles away. They were able to locate a new heater and return to the site, where they replaced the heater themselves.

“Once we found out it was going to get cold, I wasn’t going to be able to sleep anyhow,” Quick says. “I had to go back and get it fixed.”

Confidence during conflict

Quick admits he is often called in when there is an issue, and sometimes those issues have been less than pleasant. One of those times was in 2008, when an animal welfare video came out against another pork production company.

“At that time, we weren’t as formalized in our processes,” Quick says. “I would still say that we were very good caretakers of our animals, but this unfortunate industry incident highlighted that we needed to expand from that.”

Quick devoted his time to making sure every site was up to speed on animal welfare expectations and protocols, production partners were trained, and all sites’ animal handling processes were aligned with customer requirements. The updated training included National Pork Board educational materials as well as Pork Quality Assurance auditing at the sites.

“We would want any issue corrected regardless, but that brought additional leverage to the situation from the animal welfare perspective,” Quick says. “We wanted to make sure we had a system in place that ensured our animals were taken care of, ensured our people were taken care of and trained and protected — so they inadvertently didn’t do something that would put them in jeopardy, as well from not knowing any better.”

Quick says the philosophy behind the new protocols wasn’t much different from the way he had trained production staff across The Maschhoffs, but this made it more official.

According to Ken and Dave Maschhoff’s letter nominating Quick to be a Master of the Pork Industry, Quick was instrumental in building the foundation for their animal care program, which is recognized by many in the industry as a leading platform for animal welfare verification. “And, he saw the need for such a program in the mid-1990s, long before consumer pressure pushed others in the industry to adopt similar standards.”

Production, research conduit

Now as a senior consultant, first in the technical operations division and then part of the customer service team, Quick’s focus is continuing to refine husbandry skills while using new technology to drive production efficiency, animal well-being and employee engagement. In this role, he often goes into facilities to look for strengths and weaknesses, and finds possible opportunities to bring in additional resources.

One of the first thing Quick had to deal with as senior consultant was porcine epidemic diarrhea. He had been through transmissible gastroenteritis and had seen that impact, but for many of The Maschhoffs’ production partners, it was all new.

“A lot of people were just overwhelmed by the mortality and the thought of their hard work going down the drain,” Quick says. “I came in primarily to give them confidence and to say ‘Hey it’s bad. It will end, and we will get through this together and get our health stabilized and get back to production, but we will have to do some work to get there.’ ”

Over the years when The Maschhoffs have lost management, it’s been Quick who has gone in and made sure animal care procedures were still getting done correctly, and new people getting trained effectively. Another time there was a fire in a nucleus site, so Quick spent a year supporting the relocation of the nucleus population and getting the herd back to full production.

Now, with his role on the customer support team, Quick identifies key areas of the business where there may be room for improvement or that could use help from technology. Those improvements include lowering finishing mortality and nursery mortality.

“I’m a conduit between production and the research team to make sure tools and the strategy are there, and we are getting them implemented in the right manner in the field,” Quick says.

Not retiring anytime soon

Quick admits with his new role, he is out of the office more than in, but he has been lucky to have a supportive wife. When he is home, Quick and his wife of nearly 30 years, Cheryl, stay occupied keeping up with their daughter, son-in-law and two teenage grandsons next door. The entire family lives on the 80-acre farm Quick grew up on.

“I’ve got a family that supports me and is 100% behind me,” Quick says. “They are really the rock that allows me to do what I enjoy, because they are so supportive.”

The 57-year-old is also in no hurry to retire.

“After 40 years, I still come to work looking forward to what the day might hold,” Quick says. “I might go home tired nowadays, and it takes a little more time to recuperate from working with some of these guys around here — but as long as I can support our team out in the field and help bring them along, I’m ready to go.”

From the time he took the construction job as a teenager to his role now as internal consultant, this Master of the Pork Industry says he has enjoyed every minute of his time at The Maschhoffs. Quick says Wayne Maschhoff was like a surrogate dad during those early years, and he has learned so much from him as well as Ken, Dave, Bradley Wolter and many more over the years.

“I’ve been extremely blessed. I totally enjoy what I do. I’ve been able to make a comfortable living doing something I love. I work with people that I consider family,” Quick says. “My career has developed in a production setting, and I wouldn’t imagine it any other way. Over the years, I have met scores of talented individuals. If I have impacted them or the industry in any way, I am humbled and proud. I know for certain they impacted me.”

About the Author(s)

You May Also Like