New Product Tour: Automated Production Flex-Flo Unloader

Gregg Hora, Iowa hog producer; Clayton Johnson, veterinarian with Carthage Veterinary Service; Mark Knauer, North Carolina State University; and Brett Ramirez, Iowa State University, reviewed nine products in this year's New Product Tour.

Making sure your hogs are getting the feed they need is imperative to maintaining their growth and performance, and that starts at the feed bin.

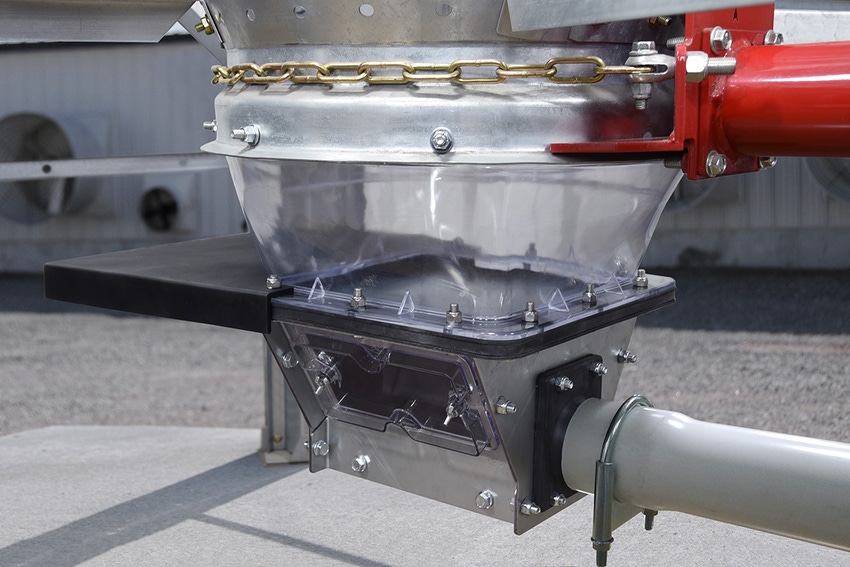

Maintaining feed flow from the bin can be difficult in varying environments. AP offers a solution with their new Flex-Flo Unloader. Its modular design and 30% larger opening improves feed flow and reduces bridging. To keep water out, tube anchor and transfer plate gaskets are made of Ethylene Propylene Diene Monomer (EPDM), improving the seal. Composite tube anchors and wear plates increase longevity.

Other features include a low-profile clear boot, composite tube anchors and wear plates, and custom-molded clear access door. Maintenance is also made easier with an increased ground clearance (as compared to standard design). Wear plates can be replaced without removing the auger, and the same boot may be used in straight and 30-degree applications.

Mark Knauer, panelist from North Carolina State University, asked Brian Rieck, AP senior manager of protein product management for North America, if the 30% more surface area reduces feed bridging events, would it also lend itself to "potentially go to a finer grind size with a feed using this unloader compared to other unloaders out there?"

Though Rieck admitted as of yet no tests have been done with a finer grind size, "but I would tell you my experience, I don't think that's going to be an issue. Basically, we've opened up that throat in the unloader so we should have more flow ability of all the free-flowing materials that you'd want to put in the bin."

Knauer followed up that "that's a pretty big deal" if a producer can potentially reduce feed particle size by 100 microns. "That's definitely something we should touch on in the future, no doubt," Rieck admitted.

With labor and biosecurity issues on the farm, Clayton Johnson, veterinarian, asked if Rieck's team has been able to "quantify some of the differences in bridging events, so the producers can help put a value proposition on it, whether it's just from the labor of going out and getting the bin unplugged or the biosecurity aspect of that."

Rieck admitted that feedback from the field continues to roll in on such matters, admitting that in "reality is that this launches later on this fall. So the field experiences come in the future, so more in 2021."

Like what you see with this product, but you have an existing system, Rieck says not to worry as "this is something that's completely backwards compatible. So if you have a system that's 10-years-old, the new design will fit up to that date and all the parts would be backwards compatible and replaceable."

Click here for more information.

New Product Tour 2020 took place during the National Hog Farmer's Global Hog Industry Virtual Conference in May, where the panel was presented a short video shared by the respective company representatives, after which a brief question-and-answer session allowed panelists to find out more about each product.

About the Author(s)

You May Also Like