Cut odor, reduce phosphorus in manure

Fast, on-farm method reduces environmental impact.

January 7, 2020

For as long as producers have been raising pigs to help feed the world, they have been battling the issue of odor. In addition to the odor issue, other elements of concern have risen as to what else may be in raw swine manure, such as antibiotics and high levels of phosphorus.

According to the National Pork Board, U.S. pork producers have made great strides in environmental sustainability by reducing land use by 76% and water use by 25%. Pork producers have also reduced their carbon footprint by 7.7% since 1960. However, society is pushing producers to get even better, and producers are obliging.

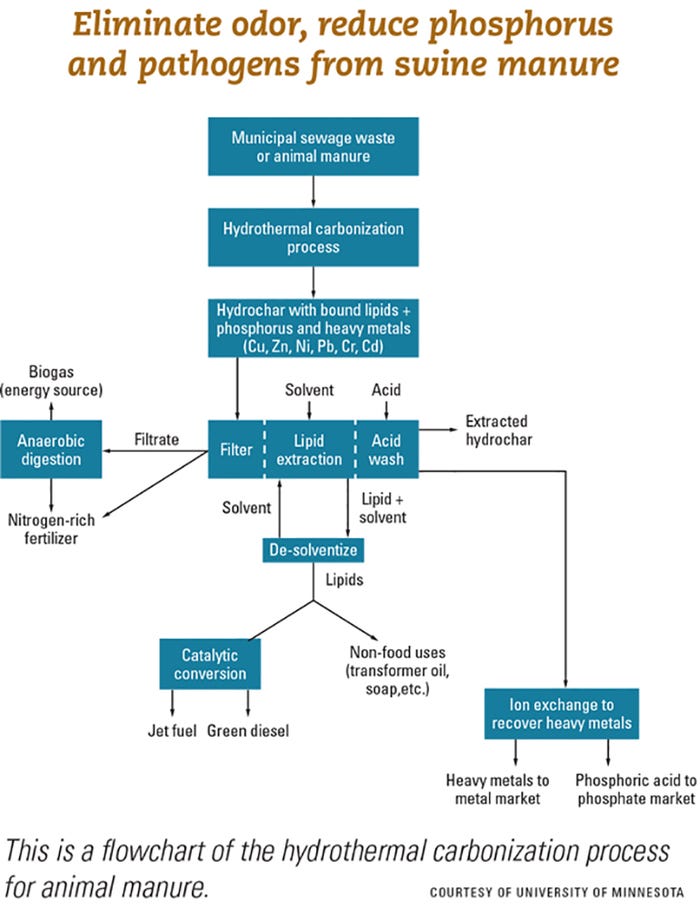

The liquid waste coming out of manure processing has several environmental effects to nearby land and water bodies. This new technology uses hydrothermal carbonization to reduce the harmful chemicals present in this liquid waste, which reduces the bad environmental effects of hog farming.

Researchers at the University of Minnesota have developed an environmentally sound, easy-to-implement method to process swine manure. Through hydrothermal carbonization, this technology can:

eliminate noxious odorous components

remove phosphorus, heavy metals and fatty acids

eradicate pathogens and inactivate antibiotics from raw manure

Treatment of manure using this method results in solid hydrochar with no offensive odor that can be easily filtered out from liquid filtrate. As 80% of the phosphorus present in the manure is retained in the solid hydrochar, it can be further treated to extract phosphorus for use as fertilizer.

With a low phosphorus content, the liquid portion can be used as fertilizer for crops without overloading the soil with phosphorus, or for production of biogas using anaerobic digestion.

Excess phosphate removal follows EPA rules

Removal of excess phosphate from liquid waste aligns with stringent U.S. EPA regulations as it prevents algal blooms, eutrophication and hypoxic conditions in rivers and lakes. Other benefits include removal of pathogens and antibiotics, reduced disposal cost and creation of a new revenue source.

Researchers say that commercially available equipment can be used to implement this process.

Another savings for producers that researchers see as a result of this technology is that the amount of land required for manure disposal will be reduced, which should translate to lower manure transportation costs.

Being kind to the environment and reducing farm inputs are what pig farmers are striving for.

Researchers say the technology can be used for animal manure management, large-scale confined animal and livestock feed operations, municipal sewage treatment plants and phosphate production.

Researchers: Kenneth J. Valentas, adjunct professor, The Biotechnology Institute at the University of Minnesota; and Michael Sadowsky, professor, Department of Soil, Water and Climate at the University of Minnesota. The project is managed by Larry Micek, University of Minnesota technology commercialization fellow. For more information, contact Micek.

You May Also Like