Turning down the heat in the sow barn

Cooling system required more than 2.5 times the electrical energy of traditional lactation housing system.

January 8, 2020

Minnesota may be known more for its long winter season, arctic temperatures and loads of snow, but it’s the short summer season that can often be taxing on the state’s pork production systems.

Most pig barns are designed and built to protect pigs against Minnesota’s cold temperatures, with less consideration for the cooling needed during the state’s sizzling summers.

All classes of pigs are susceptible to heat stress during summer, but it is the sows that are particularly sensitive around the time of farrowing and during lactation.

Currently, there are several approaches to cooling sows in the farrowing stage of production, such as increased ventilation rates, evaporative cooling pads, drip coolers, snout coolers and altered diet formulations. Each approach provides some degree of cooler temperatures for sows, but each has drawbacks.

Hence the reason researchers with the University of Minnesota West Central Research and Outreach Center and U-M’s Department of Biosystems and Biological Engineering recently set out to investigate a different approach to cooling sows that’s powered by renewable energy.

Their hypothesis was that sows cooled by a solar-powered system would be more comfortable and productive during heat stress than uncooled sows, and it would improve the carbon footprint of the farrowing operation.

Cool versus control

Two mirror-image farrowing rooms equipped with 16 farrowing stalls each were used for this study. Ventilation was provided by a combination of wall and pit fans controlled by thermostats in each room.

Each farrowing stall was fitted with a stainless steel, deep bowl feeder for sows; a nipple drinker for sows; and one nipple drinker for piglets.

The perforated flooring under the sow was made of cast iron, while the flooring under piglets was plastic-coated woven wire. Piglet creep areas were also provided with supplemental heat.

One room was designated as the control room, which was provided with no supplemental cooling for sows. The cool room was identical to the control room, except cooling pads (Cool Sow, Nooyen Manufacturing) were installed in floors beneath sows, and the pads were connected to a cooling loop. A single nipple drinker delivered chilled drinking water to sows.

Water contained in the closed loop was cooled to about 65 degrees F using a liquid-to-liquid heat pump. Pumps circulated cooled water to each farrowing stall in a parallel loop, so that each stall received cool water at a similar temperature.

Sows lying on the cooled floor transferred heat from their bodies to the floor, and this heat was then transferred to the cool water circulating in the loop.

The warmed water that exited the flooring was returned to the heat pump, where it was cooled and circulated back to the flooring inserts in the closed-loop system. The heat pump also cooled drinking water to about 60 degrees for sows.

A buffer tank was included in the cooling system to serve as a cool water reservoir to ensure consistent delivery of cool water to all 16 farrowing stalls in the cool room.

If the heat extraction capacity of the heat pump was overwhelmed, a fan coil unit included in the system extracted excess heat and directed its exhaust outside the barn.

As part of a supplemental project, the heat extracted from the sow cooling loop was moved to a separate independent system that circulated heated water through pads located in the piglet creep area.

The entire cooling system was powered by a 20-kilowatt solar array installed outside the barn. The solar array consisted of 60 solar photovoltaic panels and two power inverters.

Keeping conditions heated

Eighty-four mixed-parity, crossbred maternal-line sows were used to evaluate the efficacy of the solar-powered cooling system. Sows farrowed in three groups from June to August of 2017 and 2018, and they were assigned randomly within parity to control or cool rooms when they were moved into farrowing rooms at about Day 109 of gestation.

During the first testing of the cooling system (June 2017), cooler-than-expected weather did not provide consistent heat stress of sows, so heaters in farrowing rooms were operated to keep rooms above 75 degrees to ensure sows were heat-stressed.

Groups (n = 41 control sows and 43 cool sows) were studied during summer months. Electric consumption for all systems (ventilation, piglet heating, lights and cooling) was measured, and the performance of sows and piglets was recorded over lactation.

More electricity

The cool room consistently used more electricity than the control. The cool room used 79.6 kilowatt-hours per day, while the control room used 26.4 kWh per day across the farrowing groups. Production of electricity from the solar panels averaged 91 kWh per day.

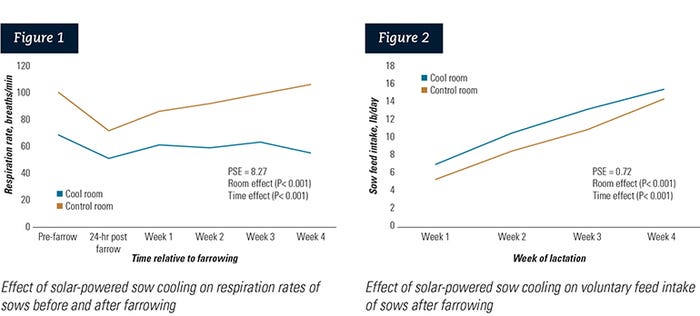

Sows housed in the cool room were more comfortable, as indicated by a lower respiration rate, 59.1 vs. 90.9 breaths per minute (Figure 1); higher feed intake, 11.6 vs. 9.9 pounds per day (Figure 2); and reduced lactation body weight loss, 31.3 vs. 47.4 pounds, compared with sows housed in the control room. Litter size at birth and weaning as well as piglet weaning weights were the same across rooms.

The cooling systems (cooled floor and cooled drinking water) and piglet heating systems studied effectively mitigated heat stress of lactating sows but did not enhance pig performance. Furthermore, these systems required more than 2.5 times more total electrical energy than a traditional lactation housing system without sow cooling.

Further analysis

While the sow cooling system studied in this project was able to significantly reduce the heat stress of farrowing and lactating sows, it did not completely eliminate heat stress. The reduced heat stress of sows did not support improvements in litter size at weaning, or the growth rate of suckling pigs.

Consequently, the expenses of installing and operating the cooling system would not be returned to pig farmers through increased income.

At this time, the researchers do not recommend commercial installation and operation of the cooling system studied in this project; however, the effects of cooled drinking water should be further assessed in independent studies. Cooled drinking water would be much easier and more economical to install than the cooled flooring in existing barns.

Researchers: Lee J. Johnston, Brigit M. Lozinski, Mike Reese, Eric Buchanan, Adrienne M. Hilbrands, Joel Tallaksen and Yuzhi Li, University of Minnesota West Central Research and Outreach Center; and Kevin A. Janni, Erin Cortus and Brian Hetchler, University of Minnesota Department of Biosystems and Biological Engineering. For more information, email Johnston.

You May Also Like