Finding the right cooling pad for sows

Blueprint Issue: Energy consumption depends upon the cooling pad design and can vary dramatically.

May 6, 2020

Heat stress in swine is the single biggest unaddressed limiting factor in pork production today. A cooling pad with limited testing or refinement may help the animals some, but it is not likely to produce optimal results for the farm operator. Heat stress is not a simple problem with a quick fix.

Considerable research continues to be conducted on problems associated with heat stress in swine, but so far, we have not seen much positive to report. Hot animals consume less feed, produce less milk, take longer to recover estrus and have lower fertility, along with a multitude of other problems.

Current research seems to be showing that a single daylong hot episode may reduce a sow’s milk production for her entire lactation. An overheated boar loses the ability to produce quality sperm for several weeks.

Neither of these circumstances may be readily apparent to the operator, causing hidden productivity losses for months.

The sows of today, with their bigger litters, generate up to 55% to 70% more metabolic heat than sows from the 1980s. Modern genetics are continuing to move toward animals that produce even more heat, with increased litter sizes.

Climate concerns are not heading in a positive direction either; and worldwide, new pork production is already concentrating in the warm geographic areas.

These factors mean that combating heat stress in domestic animals will become an even larger challenge than it is today. The combination of environment and biology controls the situation.

Effective cooling

Animals are similar to the engines in our cars and tractors. We input fuel, output work and then dump waste heat. Unfortunately, just like our engines, animals aren’t very efficient.

Thirty percent of the caloric value of feed turns to heat that the animal must give off to the environment. Typically, this is by convection into the air circulating around the animal, but hot weather makes that job tougher.

Alternative means to effectively cool animals are limited. Evaporative coolers are sometimes used to reduce the temperature of the incoming air.

These devices add moisture to the air and decrease the temperature through evaporation, but they have limited utility in regions with high temperatures and high humidity.

The next best thing is to provide fans for enhanced air circulation. Unfortunately, the range of ambient temperatures where this works well is fairly small. As the air temperature approaches the body temperature, this process becomes less effective and eventually is counter-productive.

Misters are devices that spray a light coating of water over the animal, which provides a cooling effect as it evaporates. However, these units tend to cause as many problems as they solve. Animals subjected to long-term misting can develop skin lesions and other issues.

Several other potential solutions to the heat stress problem have been tried without much success.

Animals consuming high-fat diets designed to produce less heat increment can increase total daily net energy intakes, but they are more expensive per unit of energy. Snout cooling is complex and of limited potential. Radiative cooling is expensive to install and operate.

Given the problems with existing systems, the projected increase in animal heat production and the difficulties associated with current heat removal technologies, it will become progressively more difficult to ignore this situation.

Pork operators are going to need some form of animal cooling that is economical and effective, particularly in the farrowing barns. Conductive cooling pads have the most potential to fit this need.

Right kind of cooling design

All cooling systems cost money to install and operate. However, instead of asking ourselves if the cooling pads cost more money than our current operational system, the key metric should be which cooling pad design is more efficient.

A pad that cools the building as much as the animal will not be terribly useful. A pad that cools the whole floor will be slow to react, and a pad that is too small may not produce effective results.

Additionally, a pad that isn’t well-designed may introduce unwanted internal resistance to efficient heat transfer.

At Purdue University, researchers have been taking a focused look at the problem, and we have found that differences in pad design can make a huge difference in pad performance.

Our hog cooling pad has been designed, tested and refined with multiple criteria focused on energy efficiency, including:

an optimized conductive energy path between the top surface and the coolant coil

an insulated bottom for focused cooling of the top surface

minimized thermal heat capacity of the device for quick response

intermittent convective coolant flow for effective use of coolant resources

computerized control for rapid response to varying cooling needs

instrumentation for inclusion in precision livestock automatic data acquisition systems

The design requirements of the current Purdue cooling pad have been defined by the engineers and animal scientists working on the project. These professionals have taken published knowledge about how animals react to heat stress and state-of-the-art information about heat-exchanger construction to create the cooling pad design currently being tested.

Multiple improvements to the pad and control system have been incorporated as further testing has helped the team refine the system.

The Purdue University engineers and animal scientists working on the device understand that a cooling pad must be usable on a modern hog farm without creating more problems than it solves. Our device has been developed with several constraints aimed at commercial use:

minimized top-plate temperature drops for animal comfort

durability to last multiple years, so curious pigs cannot destroy it

an automated operation that doesn’t absorb an operator’s valuable time

a simple installation that can be performed with unskilled labor

adaptability to existing buildings, as well as new construction

Market research from production hog farms was used to define these constraints. Numerous owners, managers and farmhands were asked about the introduction of new technology into swine operations, ensuring that this device will be commercially usable when introduced.

Improving the design

The Purdue University hog cooling pad design has incorporated ongoing research about how to best move heat from the top surface to the coolant coils, and how to insulate the remainder of the device from the coils.

Extensive bench testing was undertaken, and the design was revised based upon those findings to improve efficiency. There are domestic and international patents pending on the Purdue University cooling pad design.

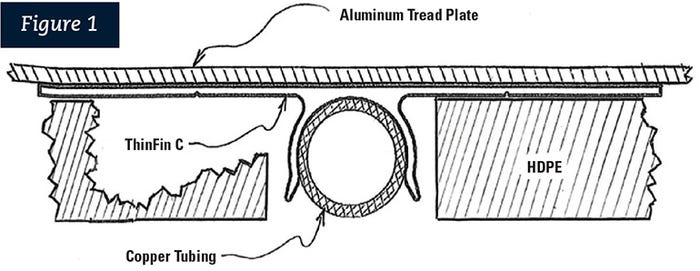

The ability of the internal pad design to enhance and not impede the transfer of heat between the animal and the coolant is crucial. The Purdue design currently incorporates a proprietary clip manufactured by Radiant Design and Supply (Bozeman, Mont.) that increases the efficiency of the conductive pathway for heat.

This ensures cooling effort is concentrated on the top surface. The Purdue pad is internally sealed and sits on a base of hard plastic, keeping environmental heat transfer to a minimum (Figure 1).

The pad can react quickly to changes in either the animal’s condition or environmental circumstances. The internal heat capacity of the device has been minimized so that animal relief is rapid and timely, and the coil design has been optimized for the heat load produced by swine.

No animals will suffer or be subjected to an extreme heat stress while waiting for the cooling system to drop to an efficient operating temperature.

Designing a process to effectively use the coolant resource is also important. The Purdue unit is controlled by a computer that receives inputs from the top surface plate and ambient conditions. It determines the proper amount of coolant flow needed to draw heat away from, but not overchill, the animal.

Intermittent coolant flows have been determined to provide the best results. This ensures that the energy resources needed to pump heat from the animal are not wasted.

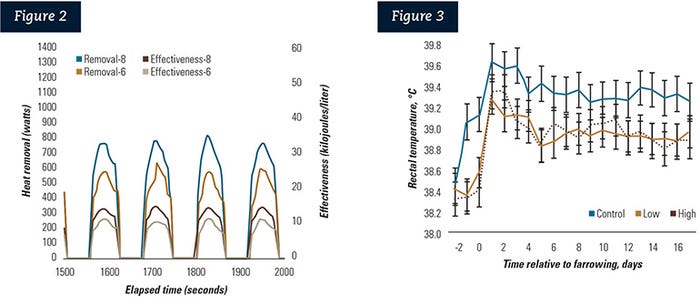

Different pads were constructed with various numbers of copper pipes, and cooling pads with eight pipes were found to be most efficient and effective in transferring heat from the sow into the cooling water (Figure 2).

A successful cooling system cannot add to the workload in the barn. The Purdue cooling pad is designed to be durable, to resist playful pigs and minimize maintenance. It is designed to last in one of the most corrosive agricultural environments and is designed not to add to the human effort required in pig production.

These features ensure the inclusion of the Purdue-designed device in a swine operation is transparent, not a burden to the operational staff and of benefit to the animals.

Animal testing results

Live-animal testing has proven that the device can take overheated animals and return them to an unstressed condition. Work continues to fully optimize both the cool-down and maintenance modes of operation in the pad.

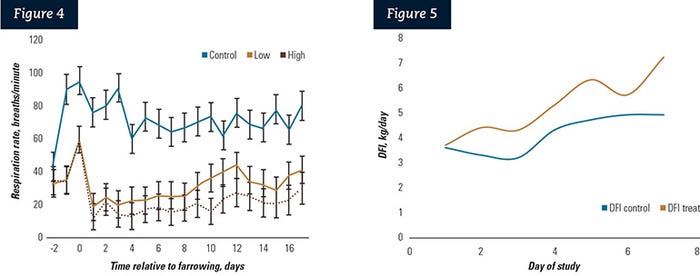

Results from our testing indicate that statistically significant reductions in skin temperature, rectal temperature (Figure 3), and respiration rate (Figure 4) occur with cooling pad use. Additionally, cooled sows have been shown to have reduced heart rates and improved lying-down behavior.

In early experimentation with the device, post-farrowing sows were subjected to a moderately stressful thermal environment. Two coolant flow rates were tested against absence of coolant flow, and both rectal temperature and respiration rate showed significant improvement between cooled and uncooled animals over a multiple-day period.

Additionally, we have been able to show that sows on cooling pads consume more feed in both late and early lactation (Figure 5).

These data clearly demonstrate the potential of cooling pads to maintain swine in more comfortable and productive circumstances during extreme thermal conditions.

The cooling pads have also demonstrated significant potential to cool overheated animals. During a controller protocol testing series, overheated animals were subjected to a variety of coolant flow cycles at extreme ambient temperatures.

The Purdue cooling pads were able to successfully decrease the skin temperature of hot animals over the course of a half-hour, with heat removal rates of over 400 watts. A decrease in respiration rates followed shortly thereafter. This clearly showed that a sow could be returned to an unstressed state while lying in a 91-degree-F (33-degree-C) barn, at the upper limit of animal tolerance.

Additionally, we’ve been able to show that a sow can be maintained in an unstressed condition in an extremely warm environment through initial and continued use of the cooling pad.

Further work is being planned to demonstrate the long-term benefits of floor cooling pads on feed intake, litter weaning weights and subsequent reproductive performance. Research has just been completed on scale-fed gilts at 90 and 95 degrees F (32 and 35 degrees C).

Our colleague Kara Stewart and her students are now examining the impact of the pads on semen quality at the same ambient barn temperatures. Pending testing includes looking at the influence of sow parity, litter size, specific animal heat production and the daily environmental cycle on the cooling pad’s performance.

We know this solution will not be needed by everyone in the pork industry, but preliminary results suggest that a strong overall economic case for cooling sows in the farrowing barn can be made for many operators.

We agree that the efficiency of the device in operation is critical. However, from our research efforts, we believe cooling systems, including cooling pads, should not be dismissed based solely on the currently available systems in the marketplace.

We firmly believe further testing will solidify the economic case for cooling, and better, more effective technology is coming. Purdue is now seeking qualified commercialization partners to produce and market this innovative technology.

Stwalley is a faculty member in agricultural and biological engineering at Purdue University. Schinckel is a faculty member in animal science at Purdue University. This research was partially supported by a Purdue AgSeed Grant. Currently, gilt and boar research is being supported by a second AgSeed grant and a National Pork Board Student Research and Education Experience grant.

References

Cabezon, F.A., Schinckel, A.P., and Stwalley III, R.M. (2017). Thermal capacity of hog-cooling pad. Appl. Eng. Agric., 33(6), 891-899.

Cabezon, F.A., Schinckel, A.P., Richert, B.T., Peralta, W.A., and Gandarillas, M. (2017). Application of models to estimate daily heat production of lactating sows. Professional Animal Scientist, 33(3), 357-362.

Cabezon, F.A., Schinckel, A.P., Smith, A.J., Marchant-Forde, J.N., Johnson, J.S., and Stwalley III, R.M. (2017). Effect of floor cooling on late lactation sows under acute heat stress. Livestock Science, 206, 113-120.

Cabezon, F.A., Schinckel, A.P., Smith, A.J., Marchant-Forde, J.N., Johnson, J.S., and Stwalley III, R.M. (2017). Initial evaluation of floor cooling on lactating sows under acute heat stress. The Professional Animal Scientist, 33(2), 254-260.

Cabezon, F.A., Schinckel, A.P., Stwalley, C.S., and Stwalley III, R.M. (2018). Heat transfer properties of hog cooling pad. Transactions of the ASABE, 61(5), 1693-1703.

Cabezon, F.A., Winslow, E., Schinckel, A.P., and Stwalley III, R.M. (2020). Influence of coil design on hog cooling pad heat transfer. Applied Engineering in Agriculture, under review.

Field, T.C., and Stwalley III, R.M. (2018). Development of a hog-cooling panel. ASABE 2018 AIM - Detroit. St. Joseph: ASABE.

Field, T.C., Schinckel, A.P., and Stwalley III, R.M. (2019). Electronic control for hog cooling pads. ASABE 2019 AIM - Boston. St. Joseph: ASABE.

Maskal, J., Cabezon, F.A., Schinckel, A.P., Smith, A.J., Marchant-Forde, J.N., Johnson, J.S., and Stwalley III, R.M. (2018). Evaluation of floor cooling on lactating sows under mild and moderate heat stress. The Professional Animal Scientist, 34, 84-94.

Parois, S.P., Cabezon, F.A., Schinckel, A.P., Johnson, J.S., Stwalley III, R.M., and Marchant-Forde, J.N. (2018). Effect of floor cooling on behavior and heart rate of late lactation sows under acute heat stress. Frontiers in Veterinary Science, 5(223), 1-8.

You May Also Like