Precision Pork: Pathway to Profitability

The pathway to future profitability for agriculture, in general, but especially for the modern meat production complex is centered as it always has been in innovation

April 15, 2010

The pathway to future profitability for agriculture, in general, but especially for the modern meat production complex is centered as it always has been in innovation.

The root meaning of the word innovation is to be “immersed in newness,” which sets itself apart in degree from the luxury of dabbling cautiously in a new idea every once in a while.

Still, one of the most vexing problems facing a maturing industry, such as the modern pork production system, is the entrenchment of conventional wisdom around a previously successful set of truisms and rules of thumb. Both were pathways from dated and less successful models, but now offer only rootedness in a status quo that is grinding its way toward the untenable — financially and socially. The plea: “Please help me become more profitable without changing anything!” is not an option.

The name of the pork production game in the next decade is managing the variance. This is a sobering thought since very few, if any, modern production systems measure variance, much less attempt to control it using a common production or financial metric. While many producers can cite their cost of production/cwt., very few track variance or standard deviation.

We live in a time when there is no such thing as a high hog price, because highly variable feed ingredient costs can nullify any hog price, real or imagined. An example is late summer 2008, when very few producers sold $100/cwt. lean hog futures for June of 2009, because corn prices suggested no profit would be available.

The time is long overdue to drop the one-dimensional focus on prices and/or costs and get serious about producing and assuring long-term profitability.

Controlling Variance

The pathway to profitability in the next decade runs squarely through the variance. Those who hope that increasing the averages of key production metrics or lowering cost of production are the best strategies for the future face a disjointed exercise without an integrated reference to profitability.

There is a class of innovation occurring in crop production that could inspire the way forward for meat protein production. The term widely used and understood is “precision agriculture,” and it represents a set of methods that recognize that crop production is a biological process that inherently exhibits variability.

Since crop production is highly variable, often time-inflexible, and requires a full year to turn once in many climates, simply sowing seeds and hoping for a desirable outcome places producers and even regions in an unacceptably risky situation. Being able to monitor the process while it is underway, observe harmful variation and intervene in a timely fashion when necessary is the basis of precision agriculture in crops.

Since the 1990s, increasingly sophisticated methods have gradually been adopted by crop producers. Technologies such as global positioning satellites (GPS); infrared photography captured by satellites and aircraft; and computer-guided tractors, combines and planting equipment are utilized.

In modern crop production, it is possible to have a GPS-guided tractor with field maps stored in an on-board computer pull a planter across a field while executing a precise, variable-seed density planting strategy utilizing criteria such as soil type, elevation (moisture-holding capacity), end of irrigation reach and other information about the field. During the growing season, infrared pictures can reveal color change patterns and identify emerging problems, such as wet spots, nutrient uptake failure, missing nutrient applications (clogged nozzles, etc.) or disease and insect infestations. These pictures can be combined with layering software to guide custom application passes of supplemental fertilizer, herbicide or insecticide, delivered precisely to where it is needed, vs. simply blanketing the field with the corrective input(s).

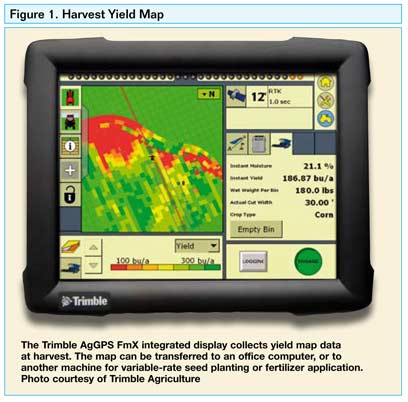

Harvest monitors on combines constantly measure harvest densities and automatically adjust the speed of the combine to minimize field losses, while other technologies keep the combine in the rows without human steering (Figure 1). When the harvest is complete, an electronic file literally provides inch-by-inch data to analyze the harvest outcome. A color- coded map can help identify areas in the field that require tiling or other amendments to the crop plan for next season.

Yield-per-acre is an obsolete figure. Today, it is possible to achieve much finer measures that track within-acre variability across a number of factors and provide an opportunity to plan all cropping procedures more precisely.

Precision Principles for Pigs

The growing world population and the accelerated cost of limited resources will demand that precision principles be applied to animal production also. To do so will require open-mindedness and adaptability to overcome the structural obstacles that could impede implementation of more precise animal production.

One of the pillars of the last great move forward for animal agriculture was to view production as a biological system that is managed rather than individual animals being raised. This requires a change in mindset — from pig production to meat production. This was a precursor of scale where production input efficiencies were dramatically altered and investment was attracted.

These efficiencies of scale — focused on production systems — de-emphasized the focus on individual animal treatment and on establishing a growing environment where, on average, the group performs best and the poor performers are culled.

The breeding herd is perhaps a partial exception and a counter example where producers moved from unobserved pen mating to handmating, and then to individual inseminations.

All-in, all-out pig movement, and then multi-site segregation and movement strategies, offered a means of potentially establishing a biosecure environment where disease organisms could be effectively prevented from entering — or, if present, kept from being transferred within the system. In some cases, where entry had already been gained, a disease was eliminated.

Recordkeeping systems gradually evolved to manage the scaled-up production systems, now located on multiple sites. Metrics were developed and applied to drive cost per unit of output to new lows.

Like many great ideas, the seeds of its own destruction were hidden in the initial, dramatic improvements in profitability and the challenge of managing larger scale and complex financial arrangements. The technologies employed largely prevented the cost-effective measurement of individual animal characteristics, such as feed intake, weight or pig health status, except when they were apparent with casual visual inspection.

Animals, especially from weaning to finishing stage, became known only by the average of their performance metrics. Today, the basic and in many cases only measure a farm can produce — production or financial — is the average or mean value.

Value of Variance

As the mean value of most production metrics has been exploited and the prospects of ongoing improvement become more costly — the law of diminishing marginal returns — the importance of measuring and improving the variance of key metrics has risen and the value to early adopters is still quite large. Yet measuring, effectively benchmarking and acting on the variance to increase profits are problematic because our status quo methods and technology will not allow it.

Once pigs are weaned, we typically have no individual animal data to measure the variance of anything. The best we can do is measure truckloads of feed and pigs for which various “totals” are summed and divided by the number of animals, pounds or hundredweights to track performance.

This deficiency was brought to our attention some time ago by particularly perceptive individuals like Bill Greenley at Swine Graphics and John Deen, DVM, at the University of Minnesota. They were pioneers who brought the methods and models associated with quality and process control to the rapidly growing and changing swine industry. Techniques such as statistical process control, sampling and programmed intervention to prevent production problems have been attempted by many production systems to varying degrees, but many producers have lost interest. Sampling is costly and very difficult, and the performance of even standard operating procedures on many farms is difficult to consistently enforce.

Deen says in many production systems there is often a subset of pigs (30-35%) that fail to reach acceptable market weights. Or producers set wide standards for “acceptable” or standard pigs — often with up to 40 lb. or more weight ranges — in which no discount from the base price by the packer is applied.

My own study of this over the last few years reveals that worldwide production systems require a 100-lb. weight range or more to capture the live weight of all the animals that “finish” the production process. Understanding this value loss is often complicated by the typical manner in which the production and financial information is collected, summarized and used to make decisions.

A Biological Process

Modern pig production is a biological process carried out within a production setting, which generates a distribution of outcomes. Pig growth is naturally a variable process, but one that can be highly responsive to the challenges induced along the way. Those challenges literally begin at implantation in the uterus — or possibly before. Adding to this natural variation is not a pathway to profits.

Challenges such as out-of-feed events, poor ventilation, wide swings in temperature, crowding, etc. result in the distribution of pig weights that, when measured in a barn prior to harvest, tend to be skewed. In the typical bell-shaped curve of pig weights in a group, the lightweight tail of the distribution curve is often longer and more spread out, and it reflects all of the challenges the pigs have encountered since implantation in the uterus. In a sense, it records the life story of each pig, but unfortunately, they are hidden in the average story of the group.

Although no pigs are ever individually weighed or measured for quality characteristics prior to harvest, each pig is typically evaluated when it is sold to the packer. Asking for and receiving the electronic files from the packer opens up the efficacy of the producer's intentions, whether they were met or fell short. This is often the first look at the variance of a production process and it can be very revealing.

From this data, a field map of pig production can be created. Like the field map generated by a modern combine, it is an encyclopedia of information ready to guide future tactics and capture latent opportunities (Figure 2 on page 7).

Rethinking Marketing Criteria

Most farms keep production and financial records completely separate and rarely share financial information with production workers. Therefore, production workers naturally focus on improving average and total production, and it is common for them to be rewarded for increasing (or decreasing) the mean value of a metric (production parameter) in their control. Generally, they have little or no knowledge of the subsequent effect on the underlying variance of production, nor the impact on profitability.

There is a common saying in pork production: “The only thing that matters is pounds out the door.” When I hear this phrase, I often point out that a pound is a measure of weight, not a measure of value or profits. A quick look at any packer pricing matrix will quickly prove the point. While a single base price may be offered at any given point in time, most packer payment schemes are pushing out 100-200 different prices with each base price, when all of the various discounts and premiums for weight and quality measures are applied as Figure 2 shows.

I often talk to farm workers responsible for selecting pigs for market and it is not unusual for them to tell me that they have never seen the pricing matrix upon which their picks will be valued. Still, they are often told, “There was too much sort loss last week!” or “The pigs are getting too heavy (or light)!”

While most producers can glance at a packer's kill sheet and evaluate the meaning of summary items, many supervisors of the marketing process never take the time to understand how their decisions affect the kill sheet summary.

The use of metric averages in the presence of underlying skewed distributions of production and asymmetric valuing schemes by packers (discounts and premiums are not equal on each side of a mid-point weight value) has led the industry to erroneous conclusions about everything from optimal average target weight, to substantial value calculation errors on questions of whether to add or remove an input. Consequently, there is a tendency to default to using average market weight and sort loss of the previous load as a guide to optimal market weight of the next load. Worse yet, it has led some to believe that if they are selling to a “heavy weight” packer, regardless of input costs, pig prices and distribution of weights marketed, selling “heavy” will reduce the average fixed costs of production.

It can be easily demonstrated that the wider the variance of weights in a distribution of market hogs, the lower will be the profit-maximizing average target weight for the group in general. Decreasing finished weight variance increases optimal target weight. But it is not just about sort loss reduction. It is about simultaneously optimizing (capturing) the greatest amount of opportunity remaining when every pig marketed is accounted for and how that changes as the target weight changes.

Conducting a single-pig type analysis of optimal target weights, based on average growth characteristics and costs in final finishing stages (the cost of adding another pound of gain), and comparing it to base price offerings can lead to substantial errors and continued opportunity losses. These are largely the methods used in the pork industry and it is far from precision agriculture.

Time for a New Metric

To begin the process of identifying and properly targeting the intentions of every hog farm organized as a business — namely, maximizing profits in a professional, safe and humane production process — a new metric has been proposed and championed by Elanco Animal Health. This metric is the “full-value pig.” Full-value pigs are those that achieve at least 90% of the return over feed cost of a single, profit-optimized pig as determined by the prevailing market price and final finishing ration cost. The opportunity remaining in each pig sold can then be compared to this standard and a residual measured to help illuminate the true cost of variance and to develop the strategies necessary to capture more value in subsequent loads and/or turns of the finishing barns.

Constructing this benchmark requires the individual pig data from the packer and a means to estimate individual animal growth and feed intake in late finishing. There are readily available methods to capture these values, so it can become an integral part of all record systems. Understanding the uncaptured opportunity for each pig produced can be estimated, totaled and compared to an intended profit standard. Doing so will lead to a more profound understanding that biological processes have variances, as well as averages, and that managing these variances is truly an unexplored pathway to increased profits.

My approach in the United States and several other countries has been to focus on reducing variance and resetting optimal system target weights as conditions change. This approach can add $2 to $5/head in profits, even in a relatively early stage of understanding and managing variance.

It is important to understand that simply weighing every pig and holding it until its optimal weight is achieved may reduce the variance of marketed weights, but it also spreads the variance of the production process from pig weight to pig days — and it is not a practical or profitable solution when building costs are factored into the analysis.

Managing variance is not the single task of those selecting which pigs to market. Expecting them to put uniform loads together from a high-variance production process with its accumulated weight spreads is not realistic.

Everyone on the farm, including those who never see a pig, has a role in variance reduction and bringing precision to modern animal agriculture. The secretary who fails to properly assign a feed delivery, or the ingredient buyer who reduces quality to reduce costs, impact farm production variance as much as, or more than, those who directly handle pigs.

Bringing precision agriculture to pork production will reduce input consumption and cost per unit of output and simultaneously increase per unit revenue. It's that sort of double impact to the bottom line that makes this approach both exciting and worthy of rapid adoption.

Equipment manufacturers and other technology providers have upcoming products that will ease the transition to individual animal assessment and the resulting opportunity gains that are possible.

Restructuring an industry is not an easy task, as unfortunately, few people get the privilege of actually implanting their answer to the question, “If you could start over today and build from the bottom up, what would be your design?” Perhaps the better question would be: “How would you rearrange your thinking before you rearrange your buildings?”

You May Also Like