Growth Performance and Economics of Increasing Dietary Tryptophan in Nursery and Finishing Diets

October 13, 2014

The use of feed-grade tryptophan in swine diets has become more economical recently due to the increased cost of soybean meal and the increased usage of distillers dried grains with solubles (DDGS).

Tryptophan is historically considered the fourth limiting amino acid in corn-soybean meal-based diets for nursery and growing-finishing pigs. The increased inclusion rates of DDGS in diets have resulted in tryptophan becoming the second limiting amino acid after lysine. As the economical availability of feed-grade tryptophan has improved, interest has grown in using it as a replacement for protein sources in swine diets.

Tryptophan plays a role in a wide range of functions besides protein synthesis, and limiting dietary tryptophan levels may cause an amino acid imbalance which can result in reductions in feed intake, and consequently reduce growth rate. The optimum tryptophan requirement in swine diets can be expressed in different ways. Using a standardized ileal digestible (SID) tryptophan requirement expressed as a ratio to lysine (tryptophan:lysine ratio) is considered a practical approach for diet formulation. As a ratio to lysine, the National Research Council (20122) suggests that the SID tryptophan requirement is 16.5% of lysine for 25- to 45-lb. pigs. For finishing pigs, the ratio increases from 17.2% for grower pigs to 17.7% in late finishing. But from a practical perspective, it is important to determine not only the growth performance, but also the economic impact of different SID tryptophan:lysine ratios.

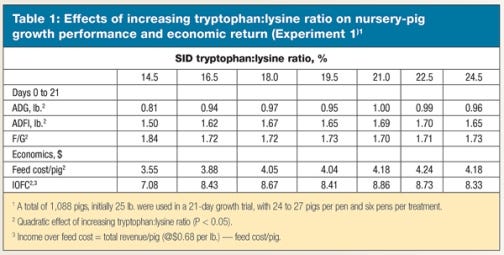

Nursery Study

In a recent nursery study to be reported at the 2014 Kansas State University (KSU) Swine Industry Day, 1,088 pigs with an initial weight of 25 lb. were fed one of seven dietary SID tryptophan:lysine ratios ranging from 14.5 to 24.5% of lysine. All diets contained 30% DDGS. Increasing the SID tryptophan:lysine ratio improved (quadratic; P < 0.05; see Table 1) average daily gain (ADG), average daily feed intake (ADFI), and feed efficiency (F/G) through the 21.0% SID tryptophan:lysine ratio.

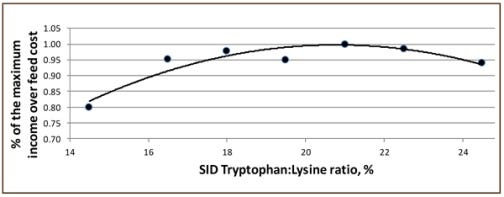

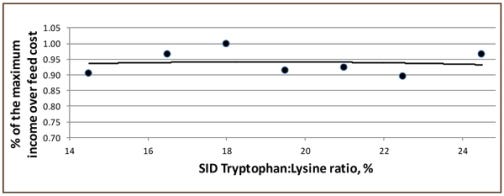

However, increasing tryptophan in the diet increased feed cost per pig. Despite the rising feed cost per pig, the added weight gain offset this, and income-over-feed cost (profitability) increased through the 21.0% SID tryptophan:lysine ratio (See Figure 1 ). This result suggests that increasing the margin of safety from 16.5 or 17.0% of lysine that is typically used in the U.S. diet formulation, to 18% or greater can be accomplished with little cost to economic performance. Also, the diets fed below 18.0% SID tryptophan:lysine were more detrimental to economic return than those fed above this range.

Figure 1:Effects of standardized ileal digestible (SID) tryptophan:lysine ratio on income over feed cost (IOFC) as a percentage of the maximum response observed (25- to 55-lb. nursery pigs).

Grow-Finish Studies

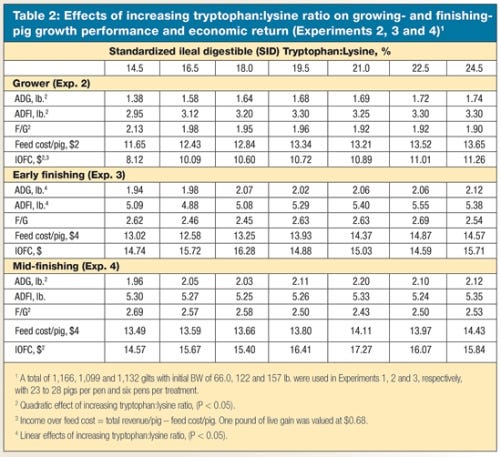

In addition to the nursery study, three 21-day growing-finishing studies with a total of approximately 1,100 gilts in each were carried out. All gilts used in each of the three studies initially weighed 66, 122 and 157 lb., respectively. As in the nursery, dietary treatments contained 30% DDGS and were: 14.5, 16.5, 18.0, 19.5, 21.0, 22.5 and 24.5% SID tryptophan:lysine ratio.

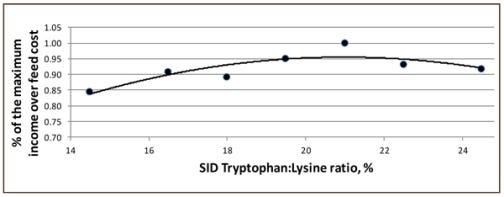

In the grower period (66 to 101 lb.), increasing SID tryptophan:lysine ratio increased (quadratic; P < 0.05) ADG. However, the rate of increase progressively diminished, particularly above the 19.5% SID tryptophan:lysine ratio (see Table 2). In addition, F/G improved (quadratic; P < 0.05) as the SID tryptophan:lysine ratio increased, with the greatest rate of change up to 21.0% of lysine.

In the early finishing phase (122 to 165 lb.), ADG increased (linear; P < 0.05) with increasing SID tryptophan:lysine ratio, but there were no differences in feed efficiency among treatments. Finally, in mid-finishing (157 to 201 lb.), average daily gain and F/G both improved (quadratic; P < 0.05) through 21.0% SID tryptophan:lysine ratio.

Economic Impact

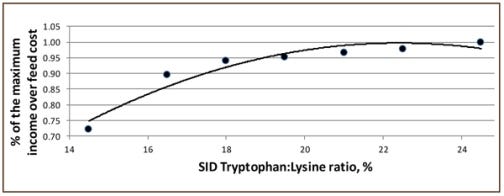

Unique about these data sets is that not only is the tryptophan requirement for pigs fed high levels of DDGS increased above current recommendations, but also the shape of economic returns to formulate to these increased concentrations. In each experiment, although diets with increased SID tryptophan:lysine ratios were more expensive, the cost was generally offset by the improvement in growth performance resulting in increased income over feed cost (IOFC) (see Figures 2, 3 and 4). These results again confirm that formulating to the least expensive diet may not result in maximum profitability or return to the producer. Producers are encouraged to visit with their nutritional adviser to evaluate the value of increasing tryptophan levels in their nursery- and finishing-pig diets. Also, a potential pitfall with adding L-tryptophan to swine diets is its flow ability; some microingredient bins may have difficulty in proportioning the proper amount of L-tryptophan in the diet. However, with the current volatility in ingredient prices, especially soybean meal and DDGS, adding L-tryptophan may be an economical option for hog diets. These studies provide good evidence to formulate diets for nursery and finishing pigs with at least an 18.0% SID tryptophan:lysine ratio, because the growth and economic risk of formulating diets below that ratio is considerably greater than formulating diets above that ratio.

Figure 2: Effects of different standardized ileal digestible (SID) tryptophan:lysine ratios on IOFC of 66- to 100-lb. growing pigs as a percentage of the maximum response.

Figure 3: Effects of different standardized ileal digstible (SID) tryptophan:lysine ratios on IOFC of 122- to 165-lb. finishing pigs as a percentage of the maximum response.

Figure 4: Effects of standardized ileal digestible (SID) tryptophan:lysine ratios on IOFC of finishing pigs as a percentage of the maximum response (157- to 201-lb. finishing pigs).

1. The authors thank Ajinomoto Heartland Inc., Chicago, IL, for partial financial support of these projects.

2. NRC. 2012. Nutrient Requirements of Swine. 11th ed. Natl. Acad. Press, Washington, DC.

You May Also Like