Fixing Feed Efficiency

A recent survey by Kansas State University (KSU) has found that despite decades of Extension education emphasizing the importance of feed efficiency in swine, pork industry participants still fall short in knowledge and production applications.

A recent survey by Kansas State University (KSU) has found that despite decades of Extension education emphasizing the importance of feed efficiency in swine, pork industry participants still fall short in knowledge and production applications.

Producer responses indicate they were unfamiliar with information behind the effects of adding fat to diets, the need to reduce particle size, the impact of feed additives and thermal effects on feed efficiency, notes Josh Flohr, KSU graduate student.

Many survey respondents were not sure of the best method of evaluating dietary energy — metabolizable or net energy, adds Swine Extension Specialists Mike Tokach and Joel DeRouchey.

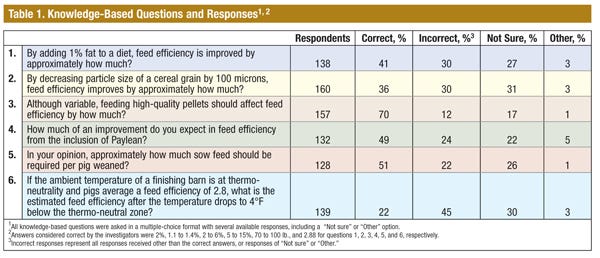

“We found a stark contrast in what respondents knew with regard to various feed efficiency areas — one being feed processing,” DeRouchey points out. “While the majority (70%) of the respondents knew that pelleting improved feed efficiency by 2 to 6%, only 36% answered correctly that reducing grain particle size by 100 microns would improve feed:gain by 1.1 to 1.4% (Table 1).

Survey Development

The feed efficiency survey grew out of a $5 million grant from USDA’s National Institute of Food and Agriculture program, which is designed to advance the knowledge of feed efficiency in swine and led by Iowa State University and KSU. It was kicked off at a symposium held last year in Omaha, NE.

The survey questionnaire sent to producers and their advisors had three objectives: 1) Determine the level of knowledge about feed efficiency; 2) Identify production practices that influence feed efficiency; and 3) Identify production gaps where more research would further improve feed efficiency.

The Web-based survey contained 32 knowledge, production and discovery questions asked of industry segments based on demographics and years of experience.

Overall, from a demographics standpoint, producers answered the questions correctly 42% of the time vs. 58% of the time for consultants, 35% of the time for academia and 32% for the “other” category.

In general, more years of experience improved the accuracy of the responses, DeRouchey notes. Following are highlights of key survey areas covered:

Defining feed efficiency: A majority of survey respondents (71%) identified feed efficiency as the amount of feed needed for one unit of live animal weight gain, and 15% responded that it is the amount of feed needed to gain one unit of carcass weight.

Dietary energy: Participants were asked to identify which energy system they use when formulating diets. Of the 129 answers, 52% said they use metabolizable energy and 23% indicated they use net energy.

When asked how much of an improvement in feed efficiency can be expected by increasing fat in swine diets by 1%, 41% correctly answered a 2% improvement (Table 1). Just 31% of producers correctly answered this question, compared to 63% of consultants.

Grinding/particle size: When asked what grain particle size is used or recommended for swine diets, 73% indicated below 700 micron parts per million (ppm). But only 4% of respondents grind or recommend grinding grain below 400 micron ppm. When asked why they didn’t grind grain to a finer particle size, the most common reason (35%) was that flowability or handling characteristics cause problems in the feeding system.

Pelleting: When asked if they feed pellets or recommend pelleting finishing diets, 59% said “no” and 41% replied “yes.” Of those responding “no,” 29% said pelleting was too expensive or that the feed processing was not available at their local mill. “These were clearly the most common reasons why individuals do not feed pelleted finishing diets,” the researchers say.

Extrusion/expanded processing: This is not used much in swine feed, but capable of making improvements in pellet quality and thus feed efficiency; 93% of respondents indicated they didn’t use or recommend these processes.

Feed additives: Several survey questions addressed the use of feed additives. When asked if they added or recommended adding copper sulfate to nursery pig diets, 69% of respondents indicated they did, while 31% did not. The majority of all industry segments affirmed this recommendation, especially those respondents with more industry experience.

The survey also asked if they feed or recommend feeding growth-promoting levels of antibiotics in nursery diets. Out of 134 respondents, 73% answered “yes” and 23% said “no.” Demographics showed that 50% or more individuals in each industry segment or age category replied “yes.” A follow-up question asked what percentage improvement in feed efficiency was expected when growth-promoting antibiotics were fed; 21% expected a 3% improvement, 20% were unsure, 16% answered 4% and 15% answered a 5% improvement. For those responding “no,” 33% said they were concerned about the potential to develop antibiotic resistance.

When asked if they use or recommend using Paylean (Elanco Animal Health) in late finishing, 70% answered “yes” and 30% answered “no.” Initial dosage was 4.5 grams/ton for 66% of respondents and 6.75 grams/ton for 26% of respondents.

Regarding use of a step-up program or a constant level of Paylean, 67% said they feed a constant level and 33% said they use a step-up program. The step-up program consisted of feeding a lower dosage for a period of time followed by a higher dosage until pigs were marketed. The most common reasons for not using Paylean were due to working with a special incentives or niche program.

Sow efficiency: The survey asked how much sow feed should be needed per pig weaned; 51% of respondents correctly answered 70 to 100 lb. Only 21% in academia and 41% categorized as “other” answered correctly.

Thermal environment: Those surveyed were asked what feed efficiency would be for finishing pigs with feed conversion rates of 2.80 if the temperature dropped 4°F below their thermo-neutral zone. Out of 139 replies, 22% answered correctly (2.88), 45% answered incorrectly and 30% responded “not sure.” Also, only 8% of “other,” 24% of consultants, 25% in academia and 25% of producers answered this question correctly.

Future of feed efficiency: When asked which topic areas would provide the largest opportunity to improve swine feed efficiency, the top three choices overall were herd health, genetics and feed processing. When asked to rank the need for future research, respondents listed health, genetics and dietary energy. Producers agreed with this ranking, but consultants and individuals categorized as “other” selected health, dietary energy and digestive tract microbiology as the most important.

Finally, individuals were asked to rank feed efficiency topics based on their knowledge. Overall, individuals believed they were most knowledgeable on particle size, amino acid and antibiotic use. While particle size was answered as an area in which they felt they had the most knowledge, it was one of the least correctly answered questions, as noted earlier.

Most respondents admitted they knew the least about extruding/expanding, digestive tract microbiology and feed additives (other than antibiotics).

Fact Sheets, Future Surveys

In an effort to improve knowledge about feed efficiency, the ISU and KSU teams have written a dozen new fact sheets focused on genetics, particle size, measuring particle size, pelleting, environmental temperature, market weight, decision tree (factorial of the different areas that will influence feed efficiency), dietary energy, amino acids, mortality, ractopamine and the influence of sow feed on whole-farm feed efficiency.

The fact sheets are available to download at www.swinefeedefficiency.com. DeRouchey will also present the survey findings at the American Association of Swine Veterinarians annual meeting in San Diego in March.

With 60% or more of the total cost of production in feed, improvements in feed efficiency can pay big dividends, Flohr and DeRouchey explain. The U.S. whole-herd feed conversion ratio is approximately 3 to 1. Improving feed efficiency by just one unit of change (i.e., from 3.00 to 2.99) represents about 140,000 tons of feed annually or feed cost savings of about $28 million.

“Efforts to fully adopt existing knowledge to optimize feed efficiency by the U.S. pork industry will improve its long-term competitiveness and the sustainability of food supplies,” Tokach says.

A follow-up survey is planned in four years to determine if the knowledge of industry participants about feed efficiency has improved, Flohr added.

About the Author(s)

You May Also Like