Finishing pigs benefit from increased dietary soybean meal

Increasing amount of dietary SBM was positively related to improved total weight gain and feed efficiency.

July 1, 2021

In a previous article highlighted in National Hog Farmer, we reported that extensive displacement of soybean meal (SBM) reduced growth rate and eroded feed efficiency in early finishing pigs (84-166 lbs..). Supplementation with crystalline amino acids negatively affected growth and feed efficiency in SBM control diets without DDGS. In contrast, crystalline amino acid addition to DDGS diets did not reduce growth, which appeared to be the result of increased intake. Feed efficiency, however, was slightly worse which was similar to the effect in pigs fed control diets. Thus, extensive replacement of SBM compromised gain and feed efficiency, the former being critical in a fixed time system.

Replacement of SBM was carefully balanced through formulation of diets that met or exceeded requirements for standardized ileal digestible lysine, methionine plus cystine, threonine, tryptophan, valine and isoleucine and were equal in net energy content. We proposed that the improvement in weight gain and feed efficiency with increasing amounts of SBM were related to growth and health-promoting components in SBM, commonly referred to as functional constituents. Indeed, it is known that SBM contains significant amounts of isoflavones, saponins, and phenolic antioxidants that can modulate immune responses and improve growth of pigs exposed to viral disease challenges (see review by Smith and Dilger, 2018. J. Anim. Sci. 96:1288-1304). In the human literature, generation of bioactive peptides, with digestion, is also known to benefit health and tissue growth. Price competitiveness of DDGS and crystalline amino acids (including tryptophan and even valine and isoleucine) have forced dietary SBM inclusion to very low levels, especially in late finishing diets. This reduces possible benefits that functional components in SBM may provide beyond serving as a well-balanced source of amino acids.

We conducted a second study, funded by the soy checkoff, to determine the impact of displacing SBM with DDGS with or without high levels of crystalline amino acids on growth performance of late finishing pigs until market weight. A total of 480 pigs with an average starting bodyweight of 183.2 ± 0.8 lbs. were blocked by weight and placed into one of 80 pens (3 gilts and 3 barrows per pen and 10 blocks per treatment). Dietary treatments were constructed as a 2 × 4 factorial arrangement with DDGS included at 0 or 20%, and crystalline lysine added at 0, 4, 8, and 12 lbs. per ton of feed. Diets were formulated to contain 0.74% and 0.67% standardized ileal digestible (SID) lysine for Phase 1 (21 days) and 2 (13 days for the heaviest 5 blocks and 20 days the lightest 5 blocks) diets, respectively. Diets were balanced for standardized ileal digestible (SID) lysine, methionine and cystine, threonine, tryptophan, valine, and isoleucine and were equal in net energy. Inclusion of SBM decreased with increasing levels of crystalline amino acids from 21.75% to 2.85% for Phase 1 and from 18.75% to 3.35% for Phase 2 for the control diets. It decreased from 18.40% to 0% for Phase 1 and 15.40 to 0% for the DDGS supplemented diets. For Phase 2 diets with DDGS, only 0.427% added lysine·HCl was required to meet SID lysine requirements for the highest crystalline amino acids supplemented diet. Thus, supplemental crystalline lysine·HCl supplementation was limited to a maximum of 8.54 lbs./ton for Phase 2 diets.

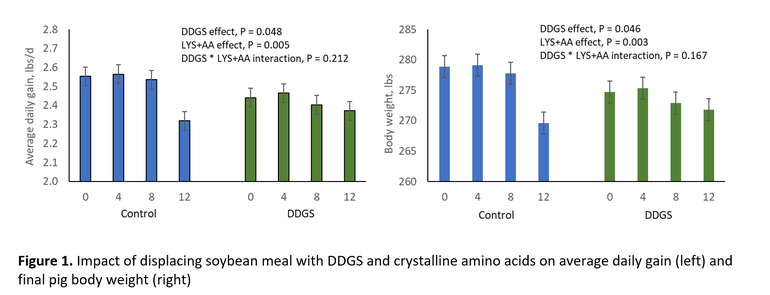

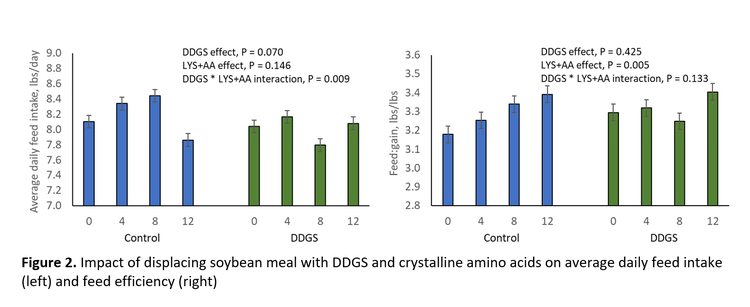

Average daily gain was reduced (P = 0.048) with the inclusion of DDGS (Figure 1) and DDGS tended to decrease daily feed intake (P = 0.070) without impacting feed efficiency (Figure 2). Supplemental crystalline amino acids linearly decreased average daily gain and worsened feed efficiency (P = 0.005). Visually, adding more than 8.0 or 4.0 lbs. of crystalline lysine·HCl/ton compromised body weight gain and feed efficiency, respectively, for SBM control diets. Pigs fed DDGS to displace SBM were 2.65 lbs. lighter at marketing with a feed efficiency that was similar between the two groups. Inclusion of 12 lbs./ton of lysine·HCl (8.54 lbs./ton for Phase 2) while balancing other essential amino acids decreased final market weight by 6.06 lbs. and increased feed:gain by 5.0% which was equivalent to 0.162 lbs. of extra feed per lb. of gain.

Ultrasound back fat thickness tended (P = 0.071) to be reduced (0.60 vs. 0.62 in.) when DDGS was supplemented, and crystalline amino acids quadratically impacted loin eye area (7.51, 7.58, 7.59, and 7.33 in2; P = 0.011). These apparent differences in ultra-sound carcass measurements were accounted for by decreased final body weight in pigs fed DDGS and crystalline amino acids. Carcass yield was reduced (P = 0.034) by 0.42% (72.62 vs. 73.04) with DDGS supplementation. Therefore, marginal carcass weight was 3.08 lbs. lower with DDGS inclusion.

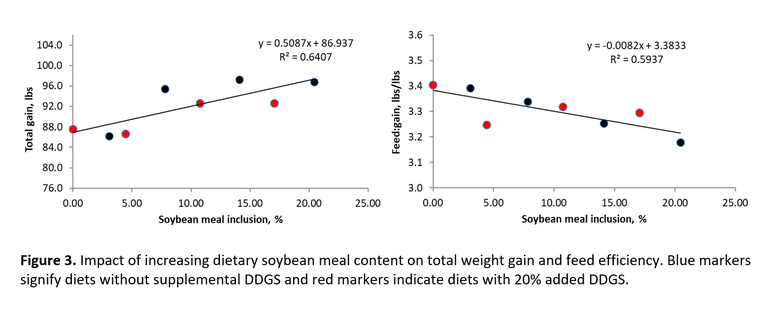

Collectively, data indicate that displacement of SBM with DDGS and crystalline amino acids, especially at the highest level of crystalline amino acid supplementation, negatively affected growth of late finishing pigs. Stated alternatively, increasing the amount of dietary SBM was positively related to improved total weight gain (R2 of 0.64) and feed efficiency (R2 of 0.59) (Figure 3). This linear response suggests that for every 1% increase in soybean meal inclusion, total gain was improved by 0.51 lbs. and feed:gain was reduced by 0.008 during this study. In the grower study previously reported in National Hog Farmer, the improvement in total gain was 0.33 lbs. for every 1% increase in soybean meal inclusion, whereas feed:gain was reduced by 0.007. The present study was conducted during the winter with high health status pigs and we speculate that the impact of SBM will be greater in pigs exposed to heat stress or respiratory health challenges.

When the data from the grower study (previous National Hog Farmer article) are combined with the data from the present finisher study, the effect of SBM level on maximizing gain is remarkable. Comparing the highest to the lowest inclusion level of SBM on live weight gain yields approximately 16 lbs. of live body weight for both the grower and the finisher study. Marginal feed efficiency, from the lowest to the highest SBM inclusion level improved by 0.17 and 0.23, for the grower and finisher, respectively. In a fixed-time scenario and especially when pigs are profitable, maximum gain is valuable, whereas strictly focusing on feed cost will compromise return over investment.

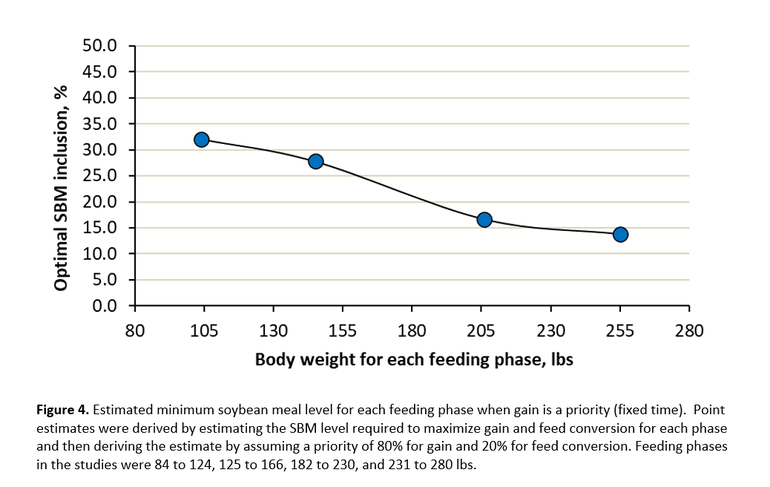

To advance our research findings to practical application, we estimated the approximate minimum SBM inclusion levels by feeding phase to maximize gain, serving as a starting point (Figure 4). Feed conversion was also improved in our studies, but the level of SBM required to optimize it was slightly different. Minimum SBM levels shown in Figure 4 favor maximum growth and assume fixed time conditions (e.g., summer). Fastest growth tends to produce the highest percentage of full-value price market pigs and least cull-value market pigs in the population. In practice, this prospective curve would be challenged and refined to derive the optimum population profit outcome. Financial optimization integrates feed input cost against value created, however, when pigs are profitable, and time is fixed, pounds of full-value pigs produced overwhelmingly drive the SBM specification. Conducting tests to further calibrate SBM inclusion must be based on population outcomes and must make the specifications applicable to the specific production system and time of year; answers will be different for summer versus non-summer. Addition of a normal summer diet as a control when developing a summer SBM optimum curve will be important to verify whether maximizing growth by preventing SBM replacement from being too extreme is beneficial.

Source: Eric van Heugten, Brooke Anderson, Jon Holt, and R. Dean Boyd, North Carolina State University, Nutrition Research LLC, who are solely responsible for the information provided, and wholly owns the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset. The opinions of this writer are not necessarily those of Farm Progress/Informa.

You May Also Like