Finer Corn Grinding Improves Efficiency

Conventional wisdom recommends that corn be milled to an average particle size of approximately 650 microns. Finer grind has been avoided due to concerns over pigs developing ulcers.

March 7, 2013

Conventional wisdom recommends that corn be milled to an average particle size of approximately 650 microns. Finer grind has been avoided due to concerns over pigs developing ulcers.

But with the vast increase in the use of more high-fiber feed ingredients, such as distiller’s dried grains with solubles (DDGS), the risk of pigs developing ulcers is reduced, thus opening the door to grinding corn to a finer particle size without experiencing problems with ulcers.

Grinding corn to a finer particle size could help pigs better utilize energy and nutrients. However, the direct relationship between corn particle size and digestibility of energy, amino acids and phosphorus is not known.

To learn more about those relationships, University of Illinois professor and swine nutritionist Hans H. Stein and doctoral student Oscar J. Rojas conducted two experiments to determine the concentration of digestible energy (DE) and metabolizable energy (ME), the standardized total tract digestibility (STTD) of phosphorus and the standardized ileal digestibility (SID) of amino acids and crude protein in corn ground to different particle sizes and fed to growing pigs.

Rolled corn was divided into four batches and processed through a hammer mill to obtain final particle sizes of 338.5, 485.0, 676.5 and 864.5 microns, respectively.

Like what you're reading? Subscribe to the National Hog Farmer Weekly Preview newsletter and get the latest news delivered right to your inbox every Monday!

In the first trial, the concentration of DE and ME and the STTD of phosphorus in the four batches of ground corn was determined using 40 barrows, 10 pigs per batch, at a starting weight of about 50 lb.

The SID of amino acids and crude protein in each of the four batches of corn was determined in the second trial using 10 barrows (starting weight of about 64 lb.) that had a T-cannula installed in the distal ileum.

In both experiments, diets consisted of corn ground to the four particle sizes, and vitamins and minerals were used.

Research Results

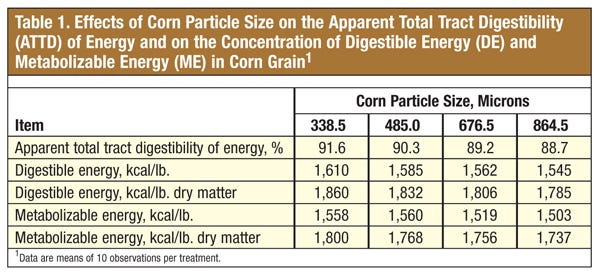

As shown in Table 1, the digestibility of energy increased from 88.7% to 91.6% as the particle size was reduced from 864.5 microns to 338.5 microns.

The concentration of DE in the corn also increased as the particle size decreased from 864.5 microns to 338.5 microns.

Likewise, Stein and Rojas found that the ME concentration in the corn increased from 1,503 to 1,558 kcal/lb. (as-fed basis) when corn particle size was reduced from 864.5 microns to 338.5 microns.

“Feed conversion rate can be improved by approximately 3.7% by grinding corn to less than 400 microns rather than to 800 microns,” Stein says. “This will save approximately 3.5% in diet costs. The savings will depend on the total diet cost. At $250/ton, the savings will be $8.75/ton of feed, or $3.50/pig produced.”

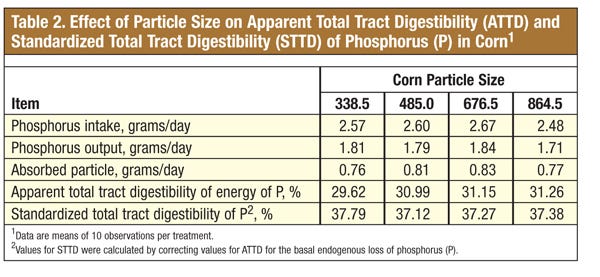

The digestibility of phosphorus was not affected by particle size of corn, and there were no differences observed among the four batches of corn for the STTD of phosphorus (Table 2).

This finding agrees with data for DDGS, which also indicate that there is no effect of particle size on the digestibility of phosphorus.

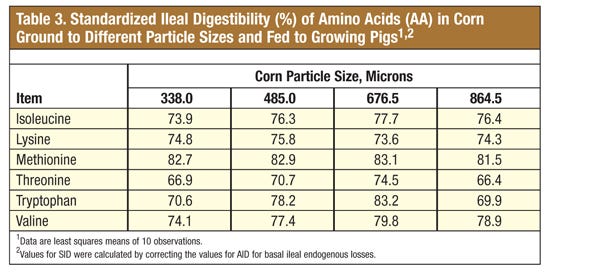

Similarly, the particle size of corn did not influence the digestibility of amino acids and crude protein (Table 3). This finding agrees with results indicating that the digestibility of amino acids in soybean meal is not affected by the particle size.

This research was supported by Pork Checkoff funds from the National Pork Board and by the Nutritional Efficiency Consortium.

Researchers: H.H. Stein and O.J. Rojas, University of Illinois. For more information, contact Stein by phone (217) 333-0013, fax (217) 333-7088 or e-mail: [email protected].

You May Also Like