Ad-lib sow feeding without bells and whistles

Simple is better when it comes to feeding lactating sows.

January 15, 2020

Sponsored Content

Correctly feeding a sow in lactation is a hard skill to learn or teach. A sow needs full access to feed to reach her full genetic potential without wasteful overfeeding.

The latest method proposed to feed lactating sows is an electronically automated system. An operator sets a feed plan for each sow, and the system delivers the ration in small "snack-sized" portions.

This system gives the operator complete control of feed intake so the sows milk heavier, better maintain body condition and prepare for rebreeding. Oh, and you can add an optional wireless activator allowing the sow to "ask" for additional portions of feed.

There is little doubt a skilled manager, with an aptitude for electronics and computers could successfully operate this type of system. But computers, smart phones, ear tags and electronics are not the only way to accurately feed sows to appetite in lactation.

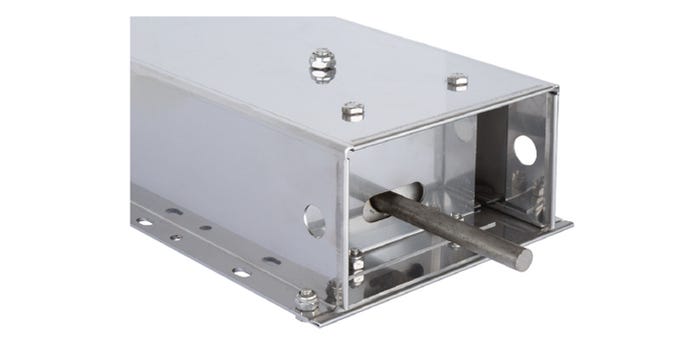

The SowMax dispenser mounts on the sow bowl, storing the feed until the sow activates a simple lever dropping a small amount of feed. The sow consumes that portion and can then decide to trigger the lever again until her appetite is satisfied.

The SowMAX system is flexible, allowing you to choose the amount of automation that is right for your operation. You can hand fill the 20-pound hopper twice each day, which provides the sow with a full day's ration. Or you can omit the hopper and install an auger or chain system to automatically fill the dispenser.

Any changes in the system are made right in the barn without a tablet or computer. Typically the feed program consists of limit feeding the sow two to three days pre-farrowing and two days post-farrowing. Fill the hopper on Day 3 and watch for feed disappearance to ensure the sow is eating. If not, that alerts the farrowing attendant the sow needs additional attention. If feed starts to accumulate in the feed pan, the trigger is adjusted down to limit the amount delivered with each stroke. It is a feeding method easily taught to even an inexperienced labor force.

Upkeep on the SowMAX system is also more straightforward than an electronically based system. The farm staff is already familiar with maintaining the augers, motors and feed drops used with an automated SowMAX system. Compare this with the expertise needed to repair a feed system based on electronics and computers.

True, the SowMAX doesn't alert your smartphone when a sow doesn't eat in a predetermined amount of time. You'll have to go into the barn to see that. Nor does it electronically record total consumption by an individual animal.

What SowMAX does provide producers is a simple-to-use method of ad-lib feeding sows 24/7 with reduced labor and maintenance, minimal feed wastage and no guesswork. To learn more about the SowMAX system, click to download The SowMAX Handbook.

About the Author(s)

You May Also Like