Solving the puzzle: How to meet your pork carcass iodine value standard

Dietary linoleic acid is the key corner piece to solving the puzzle of meeting the pork carcass fat iodine value standard.

January 25, 2017

By Trey A. Kellner, Iowa State University Applied Swine Nutrition

No matter the piece count or difficulty when solving a puzzle the general process is: first find the corner pieces, next find the edge pieces, and then group the interior pieces by color or landmarks of the puzzle. Solving how to meet the iodine value standard your packer has placed on your carcasses is a similar process and thus makes a great comparison to solving a puzzle.

The first corner piece of the puzzle of meeting your iodine value standard is, understanding what is iodine value, and why do pork processors use iodine value as a standard of pork carcass fat quality? Iodine value is a measurement of how “unsaturated” pork carcass fat is. When pork carcass fat is unsaturated it can result in carcass fat that is “soft”. Soft pork carcass fat can result in reduced shelf life, decreased belly slicing yields, and increased risk of rancidity (Picture 1). Thus, several pork packers have implemented various minimum iodine value standards to ensure that pork carcass fat quality is adequate for customers and consumers.

Another corner piece of the puzzle is the understanding that pork carcass fat iodine value can be predicted from the diet the pig consumes. From consumption to deposition, the structure of dietary fat is unaltered. Thus, if dietary fat the pig consumes is unsaturated (for example the fat contained in DDGS) the fat the pig will deposit will be unsaturated. Making it logical that you can predict the pork carcass fat iodine value from how unsaturated the dietary fat content is.

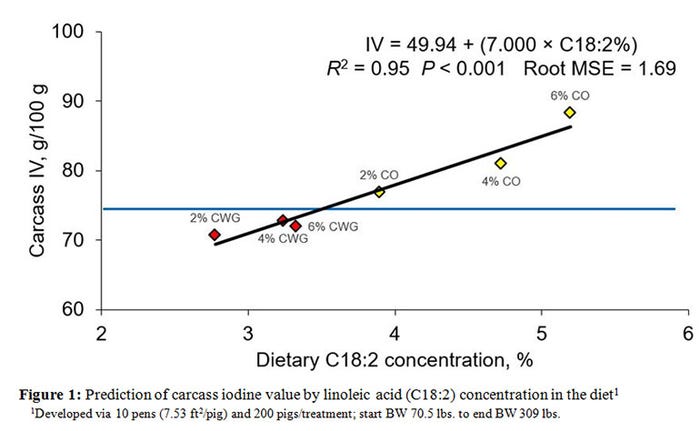

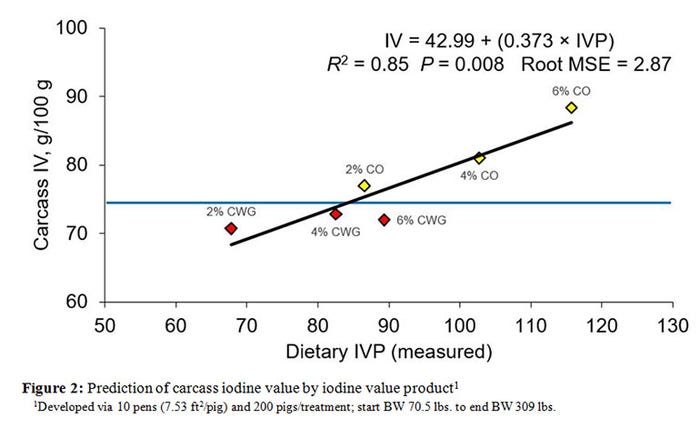

Prediction of pork carcass fat iodine value was first attempted over 50 years ago in a Danish thesis, by calculating the iodine value product. However, the IVP equation has flaws. Due to the flaws of IVP in predicting carcass IV, it has been proposed that using the linoleic acid (C18:2) content of the diet could be a more accurate predictor of carcass iodine value. Linoleic acid can only be sourced from the diet (since the pig lacks the necessary enzymes to synthesize linoleic acid) and is the major fatty acid in determining the iodine value of pork carcass fat. A recent experiment (Kellner et al., 2016) done in a commercial research facility demonstrates how dietary linoleic acid (Figure 1) is a more accurate predictor of carcass iodine value than IVP (Figure 2). Therefore to meet the IV standard placed on your carcasses by your packer, limit the linoleic acid content in the diet.

The last corner piece of the puzzle is understanding that deposited fat in the pig doesn’t just come from the diet. The second source of deposited fat in the pig is from excess energy. The pig synthesizes or creates fat from excess energy (acetyl-CoA) in a process called lipogenesis. Fat made from the lipogenesis process is largely saturated, as the pig lacks the enzymes needed to make polyunsaturated fatty acids. In most cases pigs that have a greater rate of lipogenesis (highly saturated fat) will have a lower pork carcass fat iodine value. Thus, ensure pigs stay in a positive energy balance by providing access to feed at all times, maintain health status and minimize other stressors to keep lipogenesis rates high and carcass iodine value low.

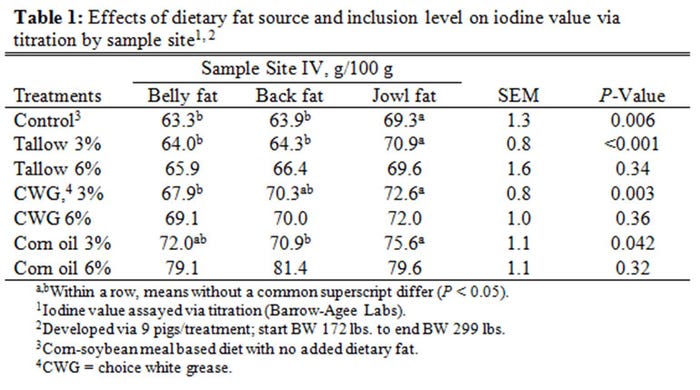

The edge pieces of solving the carcass iodine value puzzle are understanding that there are several non-dietary fat factors that can influence carcass iodine value. Heavier pigs will generally have a lower carcass iodine value as the depot fat in the pig will be more representative of fat from lipogenesis origin (highly saturated fat) versus dietary fat origin. Thus, barrows that grow faster and have a higher rate of lipogenesis than gilts will generally have a lower carcass iodine value than their gender counterparts. Ractopamine inclusion may increase carcass iodine value. Pigs fed pelleted diets may have a carcass iodine value that is greater than pigs fed mash diets. Sample location (jowl versus belly versus loin) on the carcass may also impact carcass iodine value (Table 1; Kellner et al., 2014).

The interior pieces of solving the carcass iodine value puzzle is applying these principles to your system. Understanding first, where, how and when are the carcasses being sampled? Are they being sampled in the jowl or the belly? Are the carcasses being sampled across pulls and genders? How many carcasses are being sampled (too few samples with a high proportion of gilts and or light pigs may skew your carcass iodine value average over the standard)? Second, employ dietary linoleic acid thresholds via DDGS limits or withdrawal strategies, and or feed additives that will lower carcass iodine value. Last, develop a prediction equation based off of dietary linoleic acid content, energy intake, hot carcass weight and other factors where there is variation in your system (i.e. pelleted versus non-pelleted diets) to refine dietary linoleic restrictions to ensure your meeting pork carcass fat iodine value standards without sacrificing economic returns.

In summary, dietary linoleic acid is the key corner piece to solving the puzzle of meeting the pork carcass fat iodine value standard. By placing the other pieces of the puzzle in your system, you can accurately predict the pork carcass fat iodine value of your pigs and meet the iodine value standard of your packer.

You May Also Like