Slat maintenance

Routine examination of the slats will help operators identify problems and correct them before they become a more significant issue.

June 1, 2019

Sponsored Content

Worn slat surfaces can cause foot and leg problems, additional cleaning time and premature slat failure. Most damage to concrete surfaces occurs from the acidic and sulfide compounds found in the building’s environment. Deterioration is particularly acute around waterers and feeders, especially wet/dry models.

Proper slat maintenance begins with prevention.

A typical method used for protecting slats is placing a hard, plastic mat under the feeders extending 12 inches out from the feed trough. While this product does protect the slats directly under the mat, this method in fact, moves the problem to the edges. A better solution is to protect the slats with an epoxy-based coating protecting the slat surface while allowing the acidic moisture to drain away. The same product can also be used to create a protective area under nipple and cup waterers.

Schedule routine inspections.

Routine inspections will permit an operator to spot premature wear, and to correct any problems before the deterioration becomes severe. Check the condition of the slat between groups in finishing and plan for annual checkups in gestation/breeding facilities.

Also, check the condition of the support beams under the slats. Look for developing cracks in the beams where moisture can enter and cause the supporting rebar to rust causing failure. Deterioration of the support beams is the cause of most catastrophic slat failures.

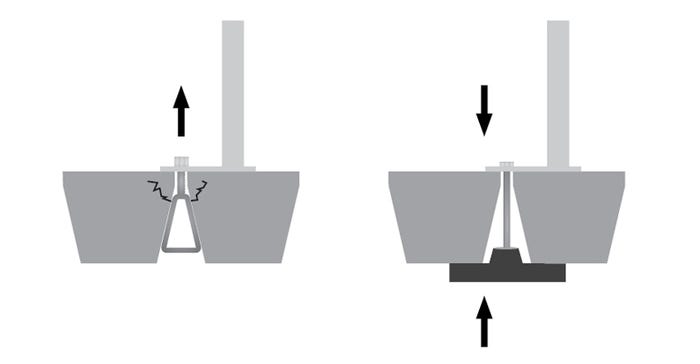

Check the T-bolts used to anchor the penning or feeders to the slats. Loose T-bolts can cause mechanical damage to slat edges. A note of caution, we strongly recommend against using any anchoring hardware that tightens by wedging between the individual slats. This type of anchor places tensile stress on the concrete and will eventually cause cracking. T-bolts, by comparison, fit under the bottom of the slat and are tightened by compression. Because of concrete’s excellent compression strength, it is virtually impossible to damage slats by over tightening a T-bolt.

For a more-detailed look at identifying the different levels of slat damage and products used for repair, download our free guide, Slat Repair and Replacement.

About the Author(s)

You May Also Like