Prevailing Over PRRS

Monte Moss, DVM, is a realist. He knows that with 110,000 pigs being finished within a six-mile radius of his northern Indiana hog farm, he will never be “home free” when it comes to security against outbreaks of porcine reproductive and respiratory syndrome (PRRS).

Monte Moss, DVM, is a realist. He knows that with 110,000 pigs being finished within a six-mile radius of his northern Indiana hog farm, he will never be “home free” when it comes to security against outbreaks of porcine reproductive and respiratory syndrome (PRRS).

“Even if your farm is filtered, we have so much PRRS around us that we will always be at high risk. But we are getting more confident month by month that the filtration system we have installed is working and keeping the herd clean,” says the Burnettsville, IN, producer.

Moss’ 1,200-sow operation has gone 36 months without a PRRS break in his sow herd. He rents one remote finishing site that is PRRS-negative and owns one finishing site, located just a half mile from the sow farm, which is PRRS-positive. “We are weaning negative pigs and have done so for a couple of years,” he says.

Isolation Doesn’t Hold

Ten years ago, Moss envisioned that his far northern corner of White County, IN, would stay pretty well isolated with just his and a neighbor’s 1,200-sow operation, 3½ miles southwest, making up the only swine operations in the area.

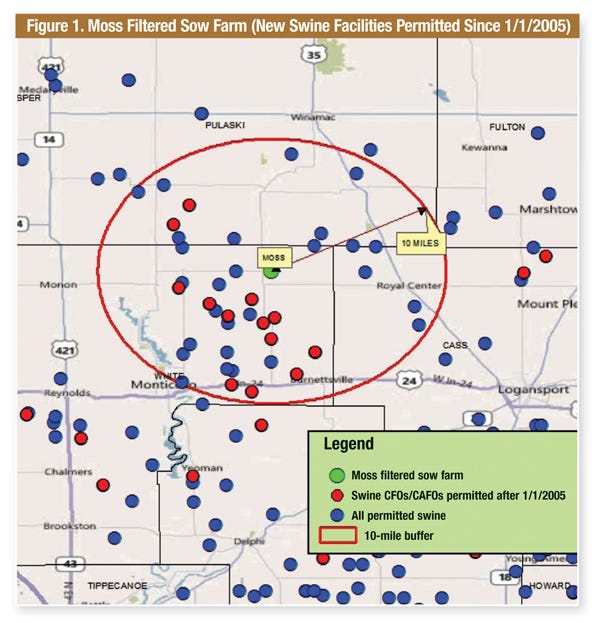

But it wasn’t in the cards. Over the last 12 years or so, close to two dozen primarily wean-to-finish operations have cropped up across the landscape adjacent to Moss Farms. And a number of them have brought PRRS along with increased pig numbers (Figure 1).

To combat this potential disease threat, Moss tightened biosecurity protocols. Thinking that the virus was coming in by trucks, he built a truck wash and required his trucks to be washed between every load of weaned pigs or market hogs.

Rendering trucks were eliminated and a composting site was constructed. The sow unit became totally shower-in, shower-out and had designated employees, trucks and tools not shared with any other site.

All those efforts didn’t stop PRRS. “We’ve had PRRS a lot of times. We have been breaking an average of once a year since 2000, but since 2003, the PRRS breaks started getting more severe,” he recalls.

In 2008, two virulent strains of PRRS struck the sow farm just four months apart, causing over 300 abortions and 10% sow deaths as well as 25% death loss in the nursery. Both breaks occurred about three weeks after weaned pigs were imported into a finishing site two miles west of Moss’s sow farm.

“I threw up my hands and said I am quitting. I am done. I can’t raise pigs here because nobody is going to buy our pigs. We were a discouraged bunch of people,” Moss says.

Becoming PRRS-Free

But Moss was intrigued by PRRS air filtration work in Minnesota and decided it was worth a try. During the summer of 2009, Moss and his staff depopulated the sow herd and began installing an air filtration system, one of the first to be installed in a commercial sow unit in the United States. Before it was completed in October 2009, the sow farm broke with PRRS again.

“We were thinking we’ve spent all this money on filtration and we’ve already broken with PRRS. But we weren’t totally finished with construction and so we were not totally filtered when we broke. Since then, we think we’ve shown that it works,” he says. “It’s given us the best production we’ve ever had.” Moss Farms has improved from producing 23.5 pigs/sow/year (p/s/y) to about 27 p/s/y. Finishing performance has also been good, he says.

PRRS has continued to pummel finishing sites in northern Indiana. But Moss’ sow farm has stayed free of the virus, based on rope tests and blood work performed by Max Rodibaugh, DVM, Swine Health Services, Frankfort, IN. Tests indicate the sow herd is now officially PRRS naïve (all PRRS-positive sows are gone). Pigs are tested every 30 days by polymerase chain reaction (PCR). Groups of 240 multi-age, negative gilts are isolated, acclimated and tested by PCR for PRRS to assure negative status before being introduced into the herd 2-3 times a year. No vaccine has been used to avoid all PRRS titers.

One group of 240 gilts caused quite a scare in October 2010 when they were tested seven days post-arrival and turned up PCR positive for PRRS. “The filtered isolation barn is just 140 ft. from our gestation barn. We were dazed,” Moss recalls. “But we sold all of those gilts and stayed negative.”

In early November 2011, an 8,000-head finisher just two miles southwest of Moss was filled with weaned pigs from an infected sow herd. In late November 2011, a 2,000-head finisher two miles west of Moss broke with PRRS. The Moss sow farm survived both of those PRRS outbreaks.

Moving to Filtration

Moss minces no words when he says he believes that his decade-plus troubles with PRRS can be traced back to aerosol transmission of the virus.

“In my opinion, I think 95% or more of PRRS transmission is by aerosol. That means as an industry we are spending 95% to 100% of our biosecurity efforts on 5% of the problem in this industry. If we are really serious about biosecurity and stopping PRRS, then aerosol and filtration are what we need to look at,” he declares.

Moss says evidence indicates there are very few PRRS breaks in June through August. Plus, he prefers to tunnel-ventilate the sow barns during those hot months. “If I did filter 100% year ’round in the sow units, I felt like we would give up the effectiveness of our tunnel ventilation. So I decided to use a bail-out system in summer.”

Basically, the difference between a total air filtration system and a bail-out system is that with 100% filtration no outside air is allowed into the building that is not filtered — 12 months of the year, 365 days a year.

��“The theory is that high temperatures and ultraviolet sunlight are very effective at killing PRRS virus and limiting transmission, so when you are moving the most air and therefore need the most filters is when you need filtration the least. I felt that if we could install enough filters to filter up to at least 70°F, then we should be safe from PRRS,” Moss explains.

Bail-Out System

The Indiana pork producer and swine veterinarian points out that a number of air filtration bail-out systems were installed in Minnesota — and all of those failed.

“In the original bail-out systems installed in Minnesota, they only filtered 85 cfm/sow, which is about 30-40% of the air. They also left their cool cells in place and did little to stop any backdrafting of fans. That means they were bailing out at 50-55°F,” he explains.

Instead, Moss targeted filtering 65-70% of the air and ended up filtering 192 cfm/sow. Cool cells and curtains were removed and bi-fold doors were installed on the end of sow barns. “We put doors in the end of barns that would open up in summer and close and seal up in winter,” he says. Aluminum roll seals with Velcro straps are used to seal up fans in winter. Air chutes made of parachute material are used to cover exhaust fans to prevent back-drafting.

“What people don’t realize is that with a cool cell, air comes through at about 400 cfm. By my calculations, with the bail-out doors open, air is moving at 911 cfm, which is really like a wind tunnel when you stand in the middle of it,” Moss says. For the adjoining bail-out doors, Moss mounted a series of 2x2 ft. angle irons on the outside of each door, then bolted all of the doors together so they operate as one unit on the end of a barn. “The angle iron gives them weight so when they close, they close down and seal pretty tight,” he explains.

He stresses that he doesn’t bail out of filtration mode until the temperature exceeds 75°F in the sow barns. “We switch from filtered mode to bail-out, tunnel mode when the last-stage fan comes on. We lock the system down and lock the bail-out doors by Oct. 1 and do not unlock them until at least mid-May,” he explains.

Moss and his team built floors and walkways in the attics of the barns to install filter banks to help distribute air throughout the barns.

To efficiently coordinate the different ventilation stages needed for all of the facets of the air filtration system, all new controllers and actuators were installed.

Air Locks

To maintain the integrity of filtration, air locks must be added to entryways. “Whenever you open a door, you’ve got negative pressure that starts pulling a lot of air into a building,” Moss states. Adding an interior door and appropriate fans creates an air lock that blows air out instead of in. Moss also added air locks to a utility room now used as a fumigation chamber for incoming supplies, at load-out areas and in a hallway that connects to the isolation barn that wasn’t sealed up during the switch over to the filtration system.

Back-Drafting

Back-drafting of fans has been identified as one of the biggest sources of air leaks with filtration. Moss designed a flap that fits over the outside of variable speed fans that works as well as a double-shutter system without the added energy needed to open two shutters. Air chutes strapped around exhaust fan cones also include a screen on the end of the fans to prevent negative pressure from sucking the material back into the cone.

As with all ventilation areas sealed for filtration, be sure to caulk all adjacent holes to prevent air leaks, he reminds.

At the Moss sow farm, manure is flushed from 12-in.-deep pits every three hours into an adjacent lagoon. “We recycle flushwater from our lagoon and that is one thing that we have been concerned about, but to date it appears that our source of the PRRS virus is totally aerosol,” he says.

Flush pipes entering the lagoon have a rubber flap over the ends of the pipes to prevent back-drafting.

Barn Issues

If your barn is older and there has been a lot of damage to moisture and insulation barriers and walls from rodents, Moss advises to build new in order to have an air-tight facility capable of accommodating an air filtration system.

Foundations with excessive cracks must also be addressed.

Filtration Costs

It becomes difficult to pin down costs to remodel an existing set of barns for filtration. Moss’ remodeled gestation and farrowing barns were built in the mid-1990s.

“I can tell you when I add in the cost of filters, pre-filters, duct work, new ceiling inlets, new controllers, roll seals over the fans, air chutes and all of the material that I bought for air filtration that it came to $90/sow, not counting labor or other changes,” Moss says. “Filtering 100% of the air would require 30% more filters and air inlets, and additional fans would be required to work at higher static pressure.”

Building air locks, adding new doors, and rebuilding the ends of the barns and attics adds quite a bit of labor cost to the project.

In his case, new ceilings and roofs were installed at the time of the remodeling project, which added to costs.

“Everybody’s barn is going to be different on remodeling, and the cost all depends on how much of it you can do yourself,” Moss explains.

Main filters are expected to be replaced every 3-4 years ($130-140 each) and pre-filters ($4 each) once a year. He estimates it will cost $75,000 to replace the main filters every three years and about $1,600 annually to replace the pre-filters.

“The total cost for filters comes to about $80,000 every three years. We produce over 30,000 pigs a year, so at over 90,000 pigs produced over three years, that puts the cost at a little less than $1.00/pig to maintain the filtration system,” Moss says.

Respect Your Neighbors

No one wants to see a regulatory

program developed for control of PRRS. But Moss believes it is time to show fellow producers some respect so that all players in the pork industry can get along.

“We have always been taught to build a sow unit in an isolated spot so that it doesn’t have the risk of disease. But when finishers want to come in and build next to that sow unit, that can result in the sow unit getting PRRS and being unable to keep it out,” he remarks.

What’s needed is some respect for neighbors to avoid those kinds of situations, Moss suggests.

About the Author(s)

You May Also Like