Infiltration: Your unplanned inlet can reduce air quality

Proper air distribution from planned ceiling inlets plays a major role in providing an environment that is acceptable for both pigs and workers.

February 22, 2017

By Brett C. Ramirez* and Harishchandra Jadhav, Iowa State University Department of Agricultural and Biosystems Engineering Graduate Research Assistants

During these winter months when low ventilation rates are typically used, it is often difficult to provide an environment inside your barn that is acceptable for both animals and workers. As discussed in our previous column, we emphasized that the design Minimum Ventilation rate is used for fan sizing, whereas, the actual environment inside the barn should be used as feedback to determine the correct ventilation rate to use.

Even when the correct ventilation rate is provided, how that fresh air is distributed within the room is critical for the quality of the environment and performance of the animals. Ideally, during cold ambient conditions, all fresh air passes through the planned ceiling inlets when a pressure difference is created across the inlets by the fans; however, numerous factors allow cold, fresh air to enter the room through unplanned inlets (“leaks”) in ceiling/wall joints, pit covers, shutters, doors, building shell, curtains, etc.

Fresh air not entering the room through the inlets is known as infiltration and can reduce air quality, be a common source of drafts, and decrease ventilation effectiveness. This column aims to clarify the definition of infiltration, its impact on the indoor environment and methods to reduce infiltration.

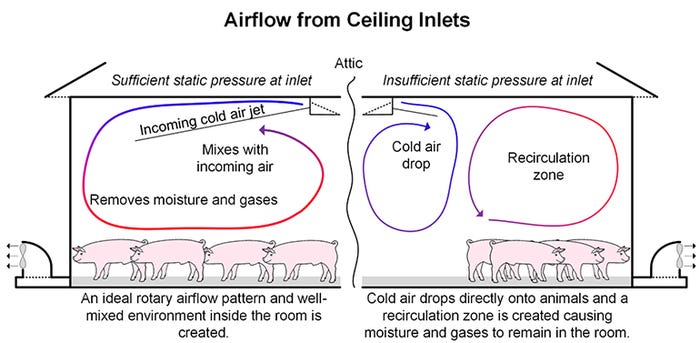

Let us first start by discussing the design and ideal operation of inlets during cold/mild conditions in a traditional negative pressure ventilation system — then we will go through how infiltration impacts ventilation. The primary inlet system is designed by engineers to ensure proper distribution of fresh air and mixing to remove generated gases and moisture from the animal occupied zone. Ideally, cold, fresh air exiting the inlet travels along the ceiling, warming up in the process, then reaches the pigs and carries away “dirty” air to the exhaust fans. If designed correctly, the flow capacity per inlet, number of inlets and opening area of each inlet will provide this ideal rotary airflow pattern and create a uniform, well-mixed environment inside the room.

The problem is, during the design phase, engineers assume a certain static pressure and thus, airspeed from the inlet. This is achievable in operation when all the design ventilation air is passing through the inlets; however, the reality is, infiltration provides an alternative route for cold air to enter through unplanned inlets, directly bypassing planned inlets, and subsequently decreasing the operating static pressure.

While construction integrity has drastically increased in tightness and quality in the last few decades, unplanned air entry into a room (i.e., infiltration) is still an integral and detrimental part of any ventilation process. Infiltration can develop stale pockets of non-uniform and undesired environments in a room and in winter can develop cold drafts around/nearby cracks. Wind effects can become amplified and decrease planned inlet performance. Infiltration has also been identified as a cause of building component deterioration, especially for positive pressure ventilation systems. Water condensation on interior claddings and water accumulation in the ceiling and walls are some other adverse effects of infiltration. Water condensation can affect animal comfort and health; whereas, water accumulation can reduce building durability.

How bad is the infiltration situation in our wean-finish barns? A recent study at Iowa State University focused on measuring, characterizing, predicting and reducing infiltration from the as-is (total) building envelope and other sources. The other sources were defined as the remaining infiltration locations after curtains (25% of as-is infiltration) and fan/pump-out housings (25% of as-is infiltration) are sealed and included locations not easily recognized, such as wall/ceiling joints. Yet, the other sources accounted for 50% of the as-is infiltration measured. The Iowa Pork Producers Association-funded study from the 17 wean-finish barns tested, found that if a barn with appropriate fan capacity and with the predicted as-is infiltration rate, that barn would be operating at a static pressure much less than what is required for adequate fresh-air mixing.

During the lower fan stages, an operating static pressure of at least 0.05 inches water column is recommended. Further, and more surprising, using the as-is infiltration rate, it was predicted that about 91%, 86% and 82% of incoming fresh-air will infiltrate through unplanned locations if a barn is operating at the typical 2, 4 and 6 CFM per head ventilation rates. The other sources of infiltration (i.e., curtains closed with ≥ 2-inch overlap and fans/pump-outs housings sealed), contributed about 58%, 55% and 49% of the fresh-air through unplanned locations at 2, 4 and 6 CFM per head ventilation rates, respectively. Air not entering a room from the planned inlets is potentially causing cold drafts affecting animal comfort and performance, in addition to ineffectively removing “dirty” air.

There are several low-cost and simple techniques that can help reduce unwanted infiltration. For example, some recommendations are a minimum 3-inch overlap on curtains, unused cold weather fans covered tightly, shutters cleaned/fixed, pump-out covers secured and sealed with sill-plate construction foam, and lastly, doorframes weather-stripped and firmly closed. Many producers are already incorporating some of these methods. While these are more easily identified areas of infiltration and relatively simple to fix, less defined locations, such as ceiling-to-side/end wall joints, can be spray foamed in the attic to substantially reduce infiltration. In addition, corroded or damaged ceiling panels may need to be patched or replaced which presents a costlier solution to infiltration.

Proper air distribution from planned ceiling inlets plays a major role in providing an environment that is acceptable for both pigs and workers. In an ideal situation, the inlet system has been designed correctly and 100% of the MV air enters a room through the planned inlets at the proper static pressure — thereby creating a well-mixed environment. Current infiltration rates are at a level that is substantially affecting our ability to provide optimal ventilation system performance and fresh-air distribution during cold-weather conditions.

The vast majority of fresh air during lower ventilation rates is originating from unplanned locations and not the planned inlet system itself. A change in building construction practices needs to be considered to reverse this situation, in addition to increased routine building maintenance. These results also point out the extent of sealing required if barns are converted to negative-pressure filtration.

The next column will go into more detail on the implications of poor facility design, construction and equipment installation.

* Corresponding author

You May Also Like