Refining Feed and Water Delivery

Often, producers and nutritionists are left with requirements to make the feeding program fit the constraints in the existing system, whether they are space shortages, small feed bins, small feed lines, old feeders that are difficult to adjust or other variables.This article will discuss facility design considerations that will minimize the constraints on the feeding program and maximize flexibility for management and diet formulation.

October 15, 2012

As swine nutritionists, we are always excited when given the opportunity to offer input into building design before the barn is built or remodeled. Often, producers and nutritionists are left with requirements to make the feeding program fit the constraints in the existing system, whether they are space shortages, small feed bins, small feed lines, old feeders that are difficult to adjust or other variables.

This article will discuss facility design considerations that will minimize the constraints on the feeding program and maximize flexibility for management and diet formulation.

Built-in Flexibility

Some key considerations apply regardless of the type of facility — farrowing, nursery, wean-to-finish, finishing or breeding/gestation — being built or remodeled.

The site should have enough space for trucks to have easy access to feed bins. Be sure power lines are placed so there is no risk to truck drivers.

The feeding system should have the flexibility to handle low- or high-energy diets, small particle size ingredients in meal or pelleted form and low- or high-density diets. New or remodeled facilities should be built with large-capacity, tandem bins. Ideally, bins should hold a semi-load of feed and the bin should be allowed to completely empty before the next load is delivered. Thus, tandem bins should be used for any feed line.

Practical diets can vary greatly in bulk density and, therefore, bins should be oversized to ensure that full loads of diets with low bulk density will fit into each bin. In some nursery or wean-to-finish situations, three bins may be desirable to allow two diets to be delivered without having to reclaim leftover feed. With starch going to alcohol production, we will likely be feeding lower bulk density diets in the future.

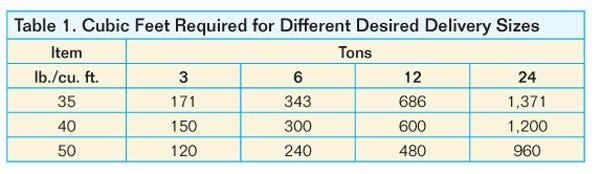

Most manufacturers use 40 lb./cu. ft. as the default bulk density in estimating bin capacity. At 40 lb./cu. ft., a bin has to have at least 1,200 cu. ft. of capacity to hold 24 tons of feed. If high-fiber ingredients are included in the diet, and the bulk density is reduced to 35 lb./cu. ft., the bin needs to increase in size to 1,371 cu. ft. to hold the same 24 tons of feed. Conversely, if pelleting increases the bulk density to 50 lb./cu. ft., the bin only needs to have a capacity of 960 cu. ft. to hold 24 tons. Similar ratios would hold for determining the capacity required for feed mixers, delivery trucks and feeders.

Feed bins should also have weather-tight lids that open and close from ground level. Feed truck augers should have shrouds that ensure feed flows into the bin without the auger resting on the bin, which can cause damage, and the vibration during unloading packs feed in the bin and reduces feed flowability. Bin design features that can help improve flowability, such as cones, automated hammers and steep, slick sides, also should be considered.

Feed lines should be at least 3 in. in diameter. Smaller lines limit flowability. Consider a disk drive instead of an auger to improve cleanout and maintain pellet quality/integrity.

The number of feed lines required will depend on the age spread of the pigs and whether barrows and gilts are separated. Ideally, each gender could be fed separately during the finishing period with a maximum age spread of one week on each feed line. The recent rise in soybean meal price makes split-sex feeding more economical than in the past.

For sows, a minimum ability to provide separate gestation and lactation diets is required. Ideally, sows in the breeding area would receive a different diet than is fed during gestation. Recent research indicates that providing separate gestation diets for early and late gestation may be profitable and should be considered when building or remodeling a facility.

As barn sizes grow, the size of water pipes needs to increase as well. For example, a line designed to supply water to 1,000 finishing pigs should be at least 1 in. in diameter (Table 1).

Feeders that Fit

Wet/dry feeders don’t work well for pigs weighing less than 30 lb. Therefore, dry feeders are recommended for nursery pigs, or wet/dry feeders are operated as dry feeders in the nursery stage in wean-to-finish barns.

Whether to use dry or wet/dry feeders in the finishing barn is a matter of preference. Wet/dry feeders increase growth rate and feed intake by approximately 5%; however, feeder adjustment has a greater impact on performance with wet/dry feeders than with dry feeders. Wet/dry feeders also waste less water than most other watering options.

Once the decision whether to use wet/dry or dry feeders is made, other critical design factors include the quality of the feeding space, number of pigs eating at each space, ease of feeder adjustment, durability and ease of cleaning.

When feeder space is designed correctly, research indicates that 11 to 12 pigs can be fed from each feeding space when meal diets are fed in dry feeders. When meal diets are fed in wet/dry feeders, stocking density should not exceed 15 pigs/feeding space. These stocking rates are considerably higher than traditional recommendations of 4-5 pigs/feeding space, but are supported by research data.

Quality of the feeding space has two principle components — can the pig eat comfortably, and will the pig be easily displaced by another pig?

Comfort is mostly dictated by the size of the feeding space. The pigs’ spatial requirements dictate the width and depth of the feeding space.

Width of the pigs’ shoulders dictates the width of the feeding space. The preferred width of the feeding space can be determined by adding 10% to shoulder width at the maximum pig weight. When pigs are marketed at more than 300 lb., the width of the feeder space should be 14 to 15 in.

The depth of the feeding space is dictated by the slope of the front of the feeder and size of the pig’s head at their heaviest weight. For pigs marketed at 270 lb. or more, the depth from the front of the feeder lip to where feed enters the feed pan should be at least 10 in. to allow pigs to eat comfortably while standing perpendicular to the feeder. Full partitions that separate feeding spaces increase comfort, prolong feeding time and reduce displacement at the trough by reducing pig-to-pig interaction during feeding.

The quality of feeder adjustment mechanisms continues to improve. The adjustment device should reside inside but near the top of the feeder so it does not get covered by feed and does not get damaged when feeders are being cleaned. The adjustment mechanism should be sturdy enough to last the life of the feeder.

Free Access to Water

For water, access appears to be the most critical element, while flow rate and quality are less important for growth performance and feed efficiency. Pigs are adept at adapting their drinking time based on flow rate to achieve their needed water intake. From a practical perspective, flow rate should be 1 pint to 1 quart/min. for 20- to 44-lb. pigs and 1 to 2 quarts/min. for finishing pigs.

A general recommendation for the number of drinkers is one nipple drinker per 15 pigs or one bowl drinker per 30 pigs. Providing multiple drinkers in a pen reduces the possibility of limiting water intake when a drinker becomes plugged or unusable.

Swinging nipple drinkers reduce water wastage vs. mounted nipple drinkers, although providing water via wet-dry feeders or bowl drinkers reduces water wastage further. Water pans also appear to reduce water wastage compared to swinging or stationary nipple drinkers; however, the pans should be elevated off the floor and be small enough to discourage pigs from trying to use them for cooling or dunging.

Some research indicates that pans do not work as well as swinging drinkers for starting pigs on water in wean-to-finish facilities. Thus, if pans are used in wean-to-finish barns, some producers have installed swinging drinkers for use during the first couple of weeks after placement.

Liquid Feeding Systems

While not popular in the United States, liquid feeding is more common in Europe and in some provinces of Canada. Liquid feeding systems offer great potential compared to conventional, dry feeding systems if used in the correct situation, such as when there is a continuous supply of liquid co-products in close proximity to the farm.

There are two options with liquid feeding — adding water to conventional dry feed or, more typically, taking advantage of inexpensive liquid by-product ingredients such as liquid whey, corn distillers’ solubles or corn steep water. Liquid feeding systems generally consist of a main mixing tank, sometimes a fermentation tank, and various pumps and pipes to deliver the liquid to feeding troughs.

Liquid feeds typically contain approximately 20 to 25% dry matter. Pigs can be fed separate meals in long troughs throughout the day or full-fed when a feed pan is equipped with a sensor to maintain water (feed) level. A separate source of water should also be provided when using liquid feeding.

Because liquid feeding involves pumps, timing of meals, mixing and delivery, expertise in computers and engineering is recommended.

Gestation Feeding, Watering

In gestation, there are two main questions for designing feed delivery systems:

1. Whether to use individual gestation stalls, group housing or a combination of both (individual stall until confirmed pregnant, then group pens throughout gestation), and

2. Whether to feed two diets — one for early gestation, another in late gestation.

There are many unanswered questions about the best group housing system and whether feeding two gestation diets can be justified economically.

With individual sow stalls, feed drop boxes must be versatile and easily calibrated. Drop boxes must be accurate and have a wide range of capacity, as one producer may need to drop 2 lb. of pelleted feed twice daily, while another may prefer a single drop of 8 to 10 lb. of a high-fiber, low-energy gestation diet. With bulky, high-fiber diets, drop boxes may need to be 12-15% larger.

Most drop boxes must hang perfectly vertical in order to deliver the correct amount of feed, although some designs seem less affected by vertical positioning (See sidebar, page 28). It is best to have some sort of flexible tube from the drop box to the solid feed delivery tube to prevent sows from hitting the tube and shaking feed from the box.

Water should be available to gestating sows at all times. Nipple drinkers are preferred over feed trough delivery, because when feed is inadvertently dropped into the trough in an empty stall space, the feed can block the flow of water to sows further down the line.

Recessed feed troughs or longer stalls should be considered to allow the sow more useable space. Pork Quality Assurance Plus standards require a sow must be able to lie down without her head resting on a raised feeder when her feet are touching the rear of the stall.

Flooring surfaces must provide slip-free footing yet not be so rough that they induce leg or shoulder sores.

In group housing systems, four main feeding systems are being used:

• Floor feeding in the pen is not recommended because of high levels of sow aggression.

• Trickle-feeding feeds groups in pens with or without shoulder barriers at the feeding trough. A box meters feed into a feed line with a very slow, rotating auger to keep the sow in her place, allowing all sows to eat their portion. Dropping about 1/4 to 1/3 lb./min. has been adopted by some.

• Electronic sow feeders (ESF) deliver a specified amount of feed to each sow based on a pre-set amount signaled by an electronic ear tag. The biggest concerns with ESF are quality and accuracy of feeders on the market, training gilts/sows to use the system, lost ear tags and having the correct number of sows per feeding station. Recommendations vary, but 50-60 sows/feeding station generally allow each sow adequate time to eat her daily feed allowance during a 24-hour cycle.

• Free-access stalls have found favor with some producers. In this system, sows can enter and leave individual stalls at will. Generally, stalls are located on either side of a common area. Research has found that sows choose to spend as much as 80% of their time in the stall in these systems. The biggest downside with free-access stall designs is the capital cost and more space

required.

From a nutritional perspective, the ESF and free-access stall systems are preferred because they allow sows to be fed individually.

With any gestation feeding system, it should be possible to feed sows without entering the facility via a timer or other electronic device.

Cup or deep bowl drinkers are preferred for sows in groups because they limit water wastage and keep floors drier.

Lactation Feeding

To maximize feed intake during lactation, many factors must be considered, including sow comfort, feeder design, water intake and feeding method. Most important is to ensure that sows have access to feed at all times.

While producers have hand-fed sows for years, many have adopted automatic or full-feeding to ensure today’s high-producing sows receive all the feed they need.

The three most popular automatic lactation feeding systems are:

1. Self-fed lactation feeder with a hopper, where feed is dispensed by the sow triggering a mechanism to drop more feed;

2. Gestation drop boxes installed for each farrowing crate that are triggered several times a day to drop feed into the lactation feeder; and

3. Tube feeder directly connecting the feed line and sow feeder, serving as a self-fed, tube-type feeder for

each sow.

Each system has inherent advantages and disadvantages that must be considered. One of the biggest questions is whether the barn staff can use it to increase feed intake while decreasing labor and minimizing feed wastage.

Most sows do not have to be trained to use self-feeders. An advantage of the automatic feed delivery systems is they require less feed storage capacity, compared to the traditional lactation feeders where up to 8 to 10 lb. is added at a time.

Producers must recognize that these systems do not diminish the time and dedication necessary to ensure that fresh feed is always available. It can be more challenging to monitor individual sow feed intake with these systems, especially the first two days of lactation. Some have opted to hand feed sows the first two days after farrowing, even though it requires more labor.

The water delivery system for farrowing crates may depend on the type of feeding system used. With an automated feeding system, it is important to locate the water source so it doesn’t spill into the feed trough where moisture will plug the feed delivery mechanism. A nipple waterer located on the side of the feeder or a cup or pan waterer is ideal in this situation.

Providing water to piglets by means of a small pan, nipple or cup waterer is recommended to supplement suckling, especially as weaning age increases and creep feed is provided.

Post-Weaning Sow Feeding

Several trials have been conducted to determine whether feed intake and nutrient concentration for the period between weaning and breeding influences the sows’ subsequent reproductive performance. Results have been mixed.

Some producers prefer to feed the lactation diet after weaning, while others offer a specific breeding diet with feed additives only fed during the breeding period. The main issue is that most gestation feeding systems are not designed to handle an additional diet.

Much to Consider

In summary, new swine buildings or major renovations to existing facilities need to take into account how diet formulation will change with high feed prices. Changing equipment capacity to handle lower or higher bulk density diets must be considered. Feed and water lines must be sized correctly to allow for adequate water pressure and prevent out-of-feed events.

Challenges to meet consumer expectations for animal well-being will also take precedence in building and feed handling designs. Yet, the resourcefulness and adaptability of swine producers will surely prevail.

See Related Sidebar Story, "Feed Drop Box Checkup."

You May Also Like