Improving nutritional value of soybean, corn co-products

Research team exploring use of fungal strains to ferment low-cost high-fiber feed ingredients.

April 15, 2021

The rising prices of corn and soybean meal are a reminder of the urgent need to consider lower cost alternative sources of nutrients in diets for growing and finishing pigs. However, most of the low-cost alternative ingredients available contain high concentrations of dietary fiber and low concentrations of amino acids, which create challenges when formulating commercial diets to achieve optimal growth performance and carcass value.

The consequences of feeding high fiber feed ingredients to growing and finishing pigs (e.g., decrease carcass yield, lower dietary energy density) were well described in previous articles (Patience, 2018), and various methods (e.g., enzymes, extrusion, pelleting) have been used to increase the digestibility of nutrients of high fiber feed ingredients (Perez-Palencia et al., 2019).

Although corn distillers dried grains with solubles (DDGS) has become a common component of growing-finishing diets throughout the U.S. pork industry, more than 50% of dietary fiber in DDGS is resistant to degradation in the large intestine of pigs even when adding exogenous fiber degrading enzymes to the diet. Results from some of our previous research have shown that the use of ammonia expansion under conditions of high pressure (300 psi) and high temperature (about 100 ℃) is effective in breaking down fiber in DDGS (Urriola et al., 2018). This process, like many others, may be effective for improving the digestibility of fiber in corn DDGS, but it is expensive and difficult to apply in large industrial scale scenarios and does not increase the nutrient content of the ingredient.

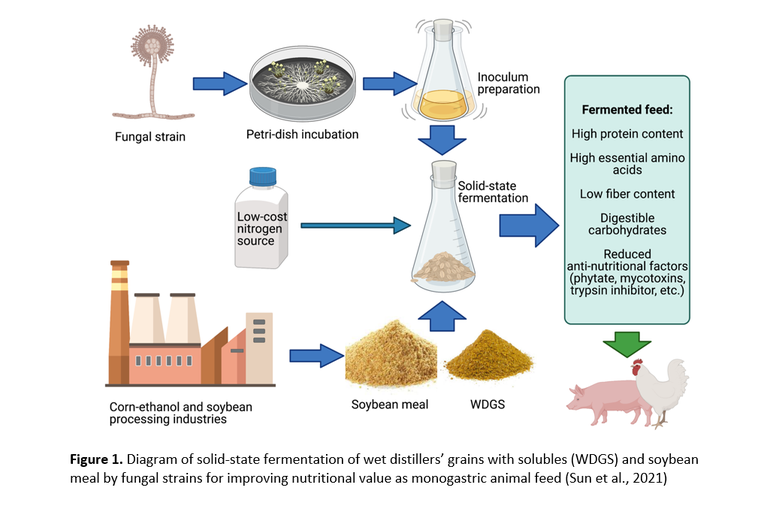

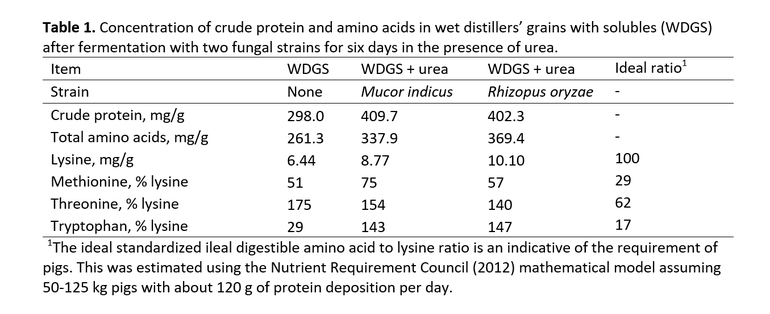

Our research team at the University of Minnesota has been exploring the use of fungal strains to ferment low-cost high-fiber feed ingredients such as wet distillers’ grains. Fungal fermentation of high fiber feed ingredients has been utilized to degrade dietary fiber and increase the content of amino acids. During ethanol production, fermentation of starch by yeast requires the addition of a significant amount of water which is later removed during drying. However, there is an opportunity of using the moisture in wet distillers’ grains with solubles for fungal fermentation. In addition, there is an opportunity to add urea as a low-cost nitrogen source that can be utilized by fungal strains for amino acid biosynthesis (Figure 1). Effectively, the concentration of crude protein and more importantly total amino acids increases in wet distillers dried grains with solubles after fermentation with either fungal strain (Table 1).

The increase in tryptophan concentration after fungal fermentation of wet distillers’ dried grains with solubles is remarkable because this is an amino acid that is in low concentration in most corn derived co-products. In practical formulation of diets for growing and finishing pigs that include corn co-products, the low concentration of tryptophan relative to lysine increases diet cost because additional sources of tryptophan are more expensive than lysine. The fermentation of wet distillers’ grains with solubles by Mucor indicus or Rhizopus oryzae increases the tryptophan to lysine ratio to one that meets the requirements of growing and finishing pigs.

In summary, there is the necessity of including feed ingredients that can decrease the environmental footprint of pork production and help farmers manage feed cost. However, the low nutritional efficiency of high fiber feed ingredients limits their overall utilization. The improvement of the nutritional efficiency could be achieved by using processes that increase the concentration of important nutrients in the feed ingredients. Fungal fermentation may be a means to improve the nutritional value of high fiber feed ingredients when coupled in the production process of the feed ingredient. However, it is necessary to scale up these processes to test the impact of fermentation on nutrient digestibility, growth performance, and the health of pigs.

Sources: Pedro Urriola, Xiao Sun, Jerry Shurson, Bo Hu, University of Minnesota, who are solely responsible for the information provided, and wholly own the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like