Effect of stall size, number of heat lamps during farrowing: Part 1

Turn, day of lactation, and sow parity were all related to piglet mortality and weight gain.

August 5, 2021

Farrowing stalls were first implemented in the 1980s to improve pre-weaning mortality rates. Most U.S. sow farms today are still using stalls of the same dimensions, despite the increasing sow and litter sizes. Coupled with increasing pre-weaning mortality, this raises the question if standard farrowing stall sizes and provision of a single heat lamp are adequately meeting the needs of modern sows and litters. This three-part series will provide insight based on results from a large-scale field study to investigate the impacts of farrowing stall layout and number of heat lamps on sow and piglet productivity and behavior (Leonard et al., 2020; Leonard et al., 2021).

Data collection for the study occurred at the USDA - ARS U.S. Meat Animal Research Center in Clay Center, Nebraska. This site was an integrated farrow-to-finish swine facility where every effort was made to mimic standard operating procedures used in commercial swine production. Data were collected on sows entering the farrowing rooms as gilts or parity 1-3, as all sows were culled after their fourth lactation cycle. All rooms operated on a six-week cycle per turn, where turn is one farrowing group (all-in, all-out batch) of sows. Sows were bred to either a commercial Landrace or Yorkshire sire, and cross-fostering of piglets occurred as needed within three days after parturition for uniformity of litter sizes.

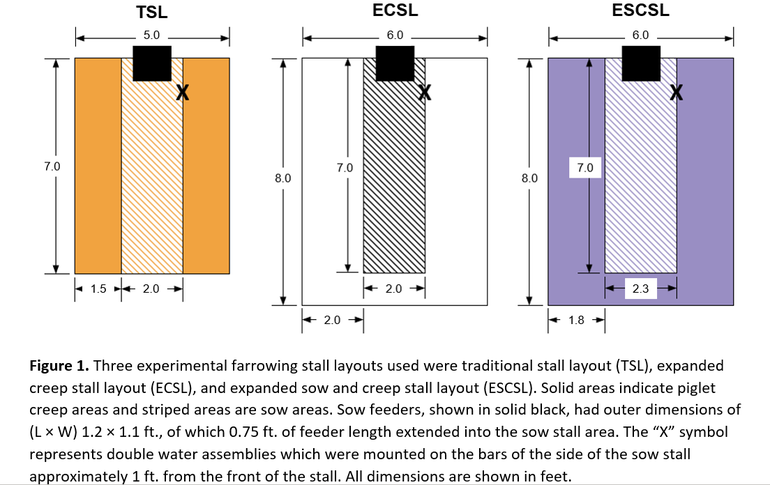

Three farrowing stall layouts were tested in this study (Figure 1). The traditional stall layout (TSL) was based on recommended farrowing stall design from the Midwest Plan Service Swine Housing and Equipment Handbook. Overall stall dimensions were 5 × 7 ft., with a 2 × 7 ft. sow crate. The expanded creep area stall layout (ECSL) also featured a 2 × 7 ft. sow crate but provided greater floor area for the piglets with outer stall dimensions of 6 × 8 ft. The third stall layout, expanded sow and creep area stall layout (ESCSL), had outer stall dimensions of 6 × 8 ft. but provided a wider sow crate with dimensions of 2.3 × 8 ft.

The three farrowing stall layouts were randomized across three farrowing rooms with each room containing 20 stalls and each stall was randomly assigned either one or two heat lamps (1HL or 2HL treatment). Each 175 W HL was covered by a metal shroud and suspended 1.8 ft. above the floor of the creep area. The HLs were centered front to back and left to right in the creep area over a 1 × 4 ft. black rubber mat. For the 2HL treatment, one HL was placed in the creep areas on either side of the sow crate.

Production data were collected for one year (September 2017 to October 2018) on 25 turns (farrowing groups) of sows by trained caretakers. Piglets were individually weighed within 24 hours after birth and one day prior to weaning. Mortality numbers, dates, and causes were recorded, as well as the number of mummies, stillborns, and overlays. Any medical treatments of both sows and piglets were recorded, and behavior data were collected for turns one through 19 using a custom computer vision system (Leonard et al., 2019).

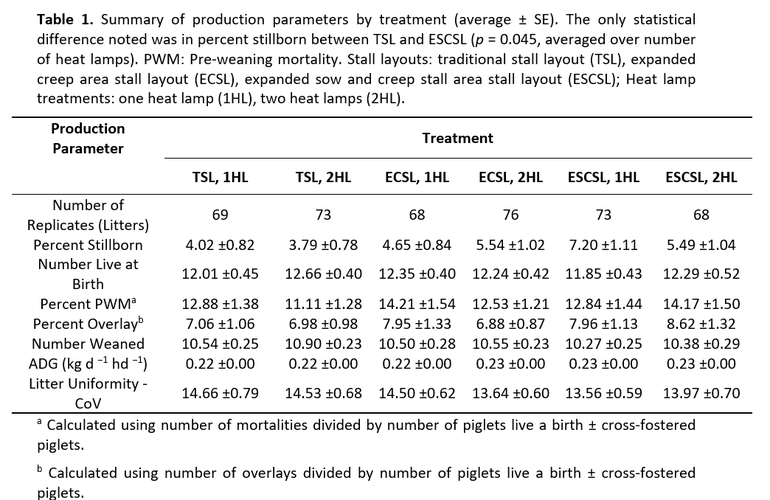

A total of 4,265 piglets from 427 litters were included in the production data analysis, with a minimum of 68 litters per treatment. Linear models were used to investigate the impact of stall layout, number of heat lamps, and relevant covariates on sow and piglet productivity. Summary metrics are presented in Table 1. The only statistical difference attributed to stall layout or heat lamp treatment was seen in percent stillborn, as piglets in ESCSL had 7% increased odds of being stillborn compared to piglets in TSL (p = 0.045). However, considering that the overall percent stillborn rate was 5.1%, this statistical difference is not of practical significance.

Though farrowing stall layout and number of heat lamps did not have meaningful influences on productivity, several of the covariates included in this study did. Turn, day of lactation, and sow parity were all related to piglet mortality and weight gain. Combined with correlations found between sow and piglet behavior and production data, the results of this study provide a more complete picture of how farrowing stall layouts and number of heat lamps impact sows and their litters. These correlations will be discussed at length in parts two and three of this series.

Source: Suzanne M. Leonard, Brett C. Ramirez, North Carolina State University, Iowa State University, who are solely responsible for the information provided, and wholly own the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

Sources

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C., Johnson, A.K., Dutta, S., Rohrer, G.A. (2021). Effects of farrowing stall layout and number of heat lamps on sow and piglet behavior. Applied Animal Behavior Science, 239(2021) 105334. doi: 10.1016/j.applanim.2021.105334

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C., Dutta, S., Rohrer, G.A. (2020). Effects of farrowing stall layout and number of heat lamps on sow and piglet productivity. Animals. 10(2):348. doi: 10.3390/ani10020348

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C. (2019). Development and application of an image acquisition system for characterizing sow behaviors in farrowing stalls. Computers and Electronics in Agriculture. doi: 10.1016/j.compag.2019.104866

You May Also Like