‘When Crates Go Away’

Done poorly, the loss of sow performance and the increase in sow mortality will explode.” That is the learned observation of Peter Kristensen, DVM, a native of Denmark, who most recently served as general manager of animal health for Boehringer Ingelheim Vetmedica, Inc. in the Ukraine, Belorussia and Kazakhstan.

July 15, 2012

Done poorly, the loss of sow performance and the increase in sow mortality will explode.” That is the learned observation of Peter Kristensen, DVM, a native of Denmark, who most recently served as general manager of animal health for Boehringer Ingelheim Vetmedica, Inc. in the Ukraine, Belorussia and Kazakhstan.

Kristensen’s presentation at PIC’s 50th anniversary symposium in Nashville, TN, in May carried the simple title, “When Crates Go Away.” But the message was clear: cutting corners when building new loose sow housing or retrofitting existing facilities can be very costly.

Drawing on producers’ experiences in the 27 European Union (EU27) countries scheduled for full loose sow housing compliance on Jan. 1, 2013, he offered some basic rules and guidelines to help anyone considering a sow housing change. The EU regulation requires 20-21 sq. ft./sow with a defined lying area (solid/defined floor with straw).

Showing a classic example of cutting corners when converting an existing sow barn, Kristensen notes the stalls were ripped out, nesting boxes and divider walls were put in place and an electronic sow feeding system was installed.

“There is nowhere to hide, no designation of a resting area or a dunging area, and sows have to pass each other, head-to-head, wherever they go,” he points out. “The sows are confused. When sows pass each other head-to-head, they will continue to have conflicts throughout gestation in a system like that.

“Regardless of design or feeding method, stay away from long and narrow pen designs. Long and narrow is a killer,” he emphasizes. “If you have a scenario in a barn where you have to feed in long, narrow pens, I prefer smaller groups. Do not attempt to put 40-50 sows in an area where sows pass each other all of the time.”

Kristensen suggests invoking a “3-meter rule” for the entrance to lying areas (resting boxes) or alleyways, where sows are likely to pass each other.

Three Basic Options

Generally, there are three loose sow housing designs/concepts popular in the EU27 — bio-fix or trickle-feeding systems, free-access stalls with straw bedding and electronic sow feeding (ESF) systems.

Trickle-feeding systems are the least expensive and can work effectively. “But the inherent danger with these systems is there is a tendency to cut corners,” Kristensen warns. “Trickle-feeding designs are an invitation to be cheap and cut corners. Err on the side of smaller groups and make sure the shoulder dividers are deep enough to separate the sows when they eat.”

The two most popular loose sow housing designs in western Europe are free-access stalls with a bedded lying area (called a “nest box”) and electronic sow feeding with a nest box.

“The design should be like an expressway for sows,” Kristensen explains. “Using the 3-meter rule, provide 3-meter-wide alleyways regardless of the design and 3-meter entrances to the nest box.”

Large, deep nest boxes are preferred over small nest boxes. He says 4.5 x 6 meters (14.85 x 19.8 ft.) is a “nice size.” The rule of thumb is 50-75% of sows are able to lie in the area during common rest periods during the day.

“Lying areas and dunging areas should be well defined. Do not run sows on traditional finisher slats. Sows need wider slats. There are some great innovations in terms of slats and passing of manure through them,” he says.

“Free-access stalls are a more expensive system, but they are more production-safe because you can get sows into the stalls, and it is easier to control their diet,” he explains. Naturally, one feeding/resting stall must be provided for each sow in the pen.

Common free-access stall pen designs have a “T” or an “L” configuration. With the T-design, two rows of stalls facing outward with a slotted dunging area in between make up the vertical portion of the “T.” The lying area is positioned horizontally in the “T” design.

Kristensen prefers a 20-cm. (8-in.) step up into the nest box from the slotted area, 0.8 sq. meters (0.96 sq. yards) of space per sow in the nest box and a solid, slightly sloped floor.

Do not try to get by with positioning the nesting area between two rows of crates, he cautions. It does not provide an attractive resting area for the sows, and adding pen dividers to the area doesn’t help. “Sows get confused about where to lie, where to eat, where to dung. When there is no defined lying area outside the stalls, sows tend to dung throughout the area, and it is impossible to keep it clean and dry,” he says.

The L-pen design is gaining popularity in Europe. Two rows of free-access stalls are positioned the same as the “T” design, but the horizontal portion of the “L” design provides a larger lying area.

Electronic sow feeding systems, also popular in the EU, allow individual feeding of sows. Small producers tend to operate the ESF systems with dynamic groups because it affords more flexibility, while large producers tend to load the pens as static groups.

The two biggest issues with ESF are competition between sows while waiting their turn to enter the feeding station and improper positioning of the feeding station. Excessive vulva biting is an indication that positioning is wrong.

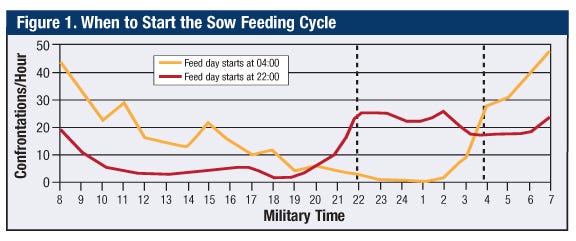

Confrontation of sows at the feeding station is highest when the feeding day starts. “When the group gets a new allotment of feed, that’s when sows fight,” Kristensen says. “If there are 75 sows on the ESF station, it’s the same 10 sows that are the first in line when a new feeding cycle starts. To help reduce confrontations, start the feeding cycle when most of the sows are resting and sleeping (Figure 1). Only the boss sows will get up.”

Free-access stalls require 10-15% more labor than ESF. “In western Europe, they estimate about eight man hours of labor per sow, so add 10-15% to that,” Kristensen explains.

In Europe, nesting material — usually straw — is required. The legislated requirement is 1.3 sq. meters (1.6 sq. yards) of bedding per sow, whether in free-access stalls or electronic sow feeding configurations.

“They will audit how much straw a producer buys in accordance with how many sows he has,” Kristensen explains. “One bale of straw in the corner with cobwebs on it will not cut it,” he assures.

Editor’s note: Kristensen became PIC’s European director on August 1.

You May Also Like