When is the best time to mix Prop 12 sows?

With high construction cost and square footage at a premium, how can producers optimize pigs born per sow space?

For those farms that are transitioning to Proposition 12 compliant facilities, new approaches need to be taken toward sow mixing and group optimization. Prior to Prop 12, sows could be weaned in stalls and groups formed either during pre-implantation (around five days before breeding) or post-implantation (after pregnancy confirmation). Now under Prop 12, sows need to be mixed at weaning and managed in pens for the entire gestation.

However, it’s up to each farm to figure out the best time to mix sows, says Matt Romoser, swine field specialist with the Iowa Pork Industry Center.

Some research has shown that mixing post-breeding can negatively impact productivity compared to other early pregnancy time points. Other studies have shown mixing at post pregnancy confirmation can lower conception rate compared to mixing at weaning, thus there is conflicting evidence about what is best physiologically and what is easiest to manage on farms. Romoser says there is an industry consensus that mixing around the time of pregnancy recognition and implantation (Days 12-30 post insemination) is a sensitive time during gestation and should be avoided.

So, what is optimal under Prop 12? Romoser says mixing sows at weaning is inevitable.

“It’s just the nature of it. Those sows have to be added into a group housing type system after they're weaned. If we regroup after breeding or pregnancy check, what's the impact of multiple mixing events having on productivity? So, multiple being, we've mixed those sows and stressed them at weaning, and now we're mixing them and theoretically stressing them again at either breeding or pregnancy check,” Romoser says. “Is it possible to have a pre- and a post-implantation mixing event, and what is the potential negative impact we have on production from that standpoint? So, we're looking at mixing sows immediately after breeding, and then again after pregnancy confirmation to normalize square footage per sow. for.”

With high construction costs and square footage at a premium, the goal really becomes how can producers optimize pigs born per sow space.

In a recent study, Romoser and the team at Gestal recently set out to evaluate animal welfare, production and economic impacts from multiple mixing events. The trial was conducted on a 3,600 head, multi-parity sow farm, remodeled from stalls to Prop 12. The farm was porcine reproductive and respiratory syndrome-virus stable at the beginning of the trial in June 2022, but became unstable mid-way through.

“Given the health challenges it was decided to stop allocating, sows and pens to treatments. So any sows that were already bred and assigned to treatment remained on test and the trial concluded midsummer of ‘23,” says Romoser.

The farm consisted of 480 free access stalls, with eight pens having 50 stalls and two pens with 40. From there sows were moved into electronic sow feeding pens. Of those 57 pens, 18 were 45-head pens equipped with three Gestal feed stations, 31 were 60-head pens equipped with four Gestal feed stations and eight were 30-head pens equipped with two Gestal feed stations.

Treatment allotments were:

Treatment 1- One mixing event at weaning and maintained through gestation.

Treatment 2- Two mixing events, formed at weaning and mixed after breeding..

Treatment 3- Two mixing events, formed at weaning, mixed after pregnancy confirmation.

Treatment 4- Three mixing events, formed after breeding, mixed after pregnancy confirmation.

Romoser says challenges came along with treatment allotment.

“With the barn being remodeled and having variation in pen size, it created challenges with assigning enough pens per treatment,” Romoser says. “The goal, obviously, when we started out, was to normalize all treatments at 24 square feet. We wanted all sows to at least have a similar environment at the beginning of the trial. So, in this case, if we have a 50-head sow free access pen, and we're trying to assign those to a 45-head Gestal pen effectively, we need 90% of those sows to come into heat within five days in order to be able to fully stock that pen at 24 square feet.”

This resulted in Treatments 1 (n=5) and 3 (n=5) having significantly lower number of pens enrolled compared to Treatments 2 (n=26) and 4 (n=32).

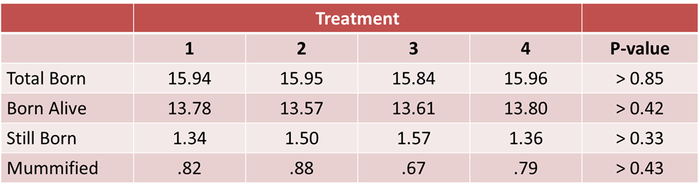

When analyzing the litter data, no differences were detected for total born or born alive across the treatments (Table 1.). From there the team analyzed pigs born/sow space to evaluated barn efficiency within treatment.

Romoser. Table 1. Effect of mixing on litter parameters.

To do so, final pen inventory was used to determine square feet per sow prior to farrowing. Final square footage was divided by 24 to obtain adjusted sow space for Prop 12 requirements. When the team looked at Treatments 2 and 4, they observed a dramatic improvement in maximizing space (1.49 spaces/sow vs. 1.17 spaces/sow). This in part because the Treatment 4 sows were normalized after 35 days gestation to 24 square, thus experienced less group attrition for the rest of gestation.

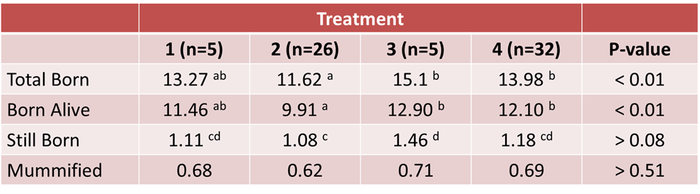

As a result, when pig born/sow space was assessed, Treatment 4 had significantly more total born compared to Treatment 2 (13.98 vs. 11.62), and born alive (12.10 vs. 9.91) (Table 2.).

Romoser. Table 2. Effect of mixing on pigs born/sow space.

From this data, the team concluded that two or three mixing events did not negatively impact litter size, however regrouping sows post pregnancy check and normalizing to 24 square feet resulted in more pigs born per sow space.

This study provides evidence for pork producers of the potential impact of mixing and how they can manage sows to maximize throughput in a Prop 12 setting. To gain a better understanding of the underlying biological effect of mixing, Romoser says future studies will need to be conducted controlling for beginning square footage and variation in return to estrus within group formed at weaning.

About the Author(s)

You May Also Like