Troubleshooting farm electrical systems

A farm’s electrical system requires regular attention.

October 14, 2019

Sponsored Content

The electric systems in livestock and poultry buildings are not maintenance-free. The corrosive gases and high humidity present in these facilities deteriorate electrical components at a faster rate than residential structures.

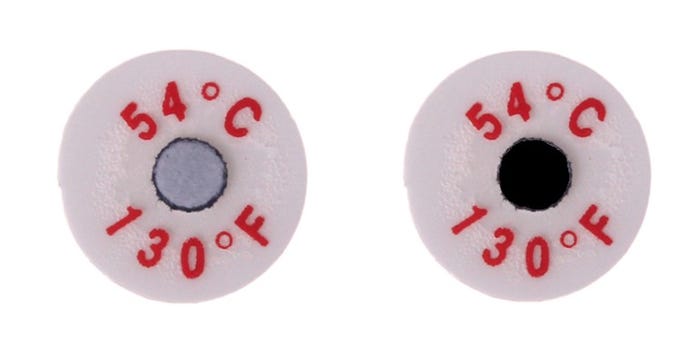

The breaker panel is one of the most common areas of electrical failure. Current flow through corroded or loose connections raises the temperature causing the circuit breakers to trip unexpectedly. Spot temperature indicators, which install directly on the breakers, offer a simple method of monitoring potential overheating. The indicators turn black if the breaker temperature reaches 130 degrees F, alerting of a potential problem. The indicators are inexpensive, costing a little over a dollar each.

Replace worn-out electrical panel boxes. Rusted areas can allow moisture and corrosive gases to enter and damage wiring connections.

Check receptacles for loose connections and damaged plug ends. Replace missing or damaged covers.

Check feed and fan motor cords for damage. The insulation on cords deteriorates with age, developing cracks, which allow moisture into the copper wires. Do not repair power cords; instead, replace them. Do not substitute extension cords for permanent cords.

If the service entrance is overhead, check the straps that secure the mast and verify the weatherhead is in place.

Entrance panels are grounded to provide an easy path for electricity to flow to the earth. Permitting the current to flow to the ground allows a circuit breaker to trip, preventing fire or electric shock. Check to see the ground rod connection is not broken or missing. Also, when replacing a grounding rod connection, choose a bronze lug for its superior corrosion resistance compared to galvanized pipe clamps.

When adding equipment, such as extra fans or larger feed system motors have an electrician verify the existing wiring is of adequate size. Additional loads can reduce the voltage to the equipment. The low voltage causes motors to overheat, which reduces their operational life.

A critical eye and prompt response to issues as they arise will keep a facility’s electrical system in good working order. On buildings over 10 years of age, schedule an annual spring inspection with a certified electrician before summer’s peak electrical usage.

About the Author(s)

You May Also Like