Don't rely on a silver bullet

Invest in a full set of comprehensive processes to fully understand African swine fever risk.

November 8, 2022

In November, farmers across the United States are focusing on finishing the harvest and fine-tuning hog barn ventilation systems for cooler temperatures. Since it is still close enough to Halloween for people to be thinking about scary things such as werewolves while eating leftover candy, perhaps it is not too off-topic to bring up the mythical silver bullet.

Some might recall that a silver bullet shot through the heart would always kill the legendary werewolf. Therefore, when seeking a single solution, regardless of the complexity of the problem, that solo action or "just one thing" is called the "silver bullet." Thankfully, there is no such thing as werewolves.

Unfortunately, there is also no such thing as a silver bullet when it comes to a simple way to understand the risk of African swine fever virus spread to and from pork harvest facilities in the United States if an ASFv outbreak occurred.

To better understand the ASFv spread risk to/from US pork harvest facilities, a research team at UMN has embarked on a pathway analysis as the first step in that risk assessment process. This first step is required when tackling the often complex and variable methods of moving pork, pork products, byproducts and waste from a harvest facility.

Briefly, this ASFv pathway analysis is a framework that identifies the potential routes of ASFv introduction and spread from the harvest premises. The analysis is based on current harvest facility production systems approaches and available scientific information. Completing this type of analysis in a timely manner during an outbreak is typically impractical.

Analyses conducted proactively, before an outbreak occurs, provide the framework necessary for decision-makers to identify and better understand the different pathways associated with the harvesting of pigs in the United States. This pathway analysis is an important component of a complete risk analysis. A subsequent risk assessment will more fully evaluate significant potential risks identified via the pathway analysis.

The literature and expert opinions that are being used to guide the pork harvest facility ASF pathways analysis are based primarily on experimental work in which a limited number of animals and specific virus strains were analyzed or on case reports from ASFv-infected countries. The pork harvest facilities ASF pathways assessment, when completed, should not be used to predict the spread of ASFv in an outbreak since actual ASFv behavior in an outbreak could vary significantly depending on the circumstances.

The pork harvest facilities ASF pathways assessment evaluates the most up-to-date available science and solicits opinions from experts when data is lacking. The analysis is proactive in nature and the scenarios, pathways, and movement types assessed are based on the current practices and regulations applicable to pork harvest facilities in the United States. The purpose of this pathway analysis is to provide insight into the potential pathways for ASFv spread associated with the movement of pigs to harvest facilities and pork products to further distribution.

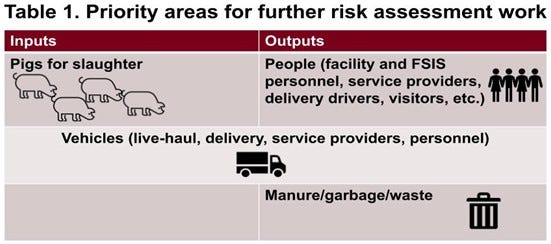

The pathway analysis has preliminarily identified several inputs and outputs that may potentially be associated with the likelihood of ASFv transmission during the pork harvesting process, as summarized in the Oct. 3, 2022 article. More importantly, the pathway analysis has identified several gap areas (Table 1). Further work is needed and ongoing to fill these gaps and better estimate the risk of disease spread associated with each pathway in order to be able to provide targeted recommendations to allow for the movement of pigs in these scenarios.

It is important to understand that the pathway analysis does not determine the amount of risk. Instead, the pathway analysis seeks to overcome the problem of understanding the complexities of modern harvest facilities. The pathway analysis methods provide meaning to harvest facility inputs, outputs and processes. This helps not only with the interpretation of what this might mean in terms of ASFv risk, but also with planning for future research work in areas that appear to be the most important or have the greatest consequences.

A pathway analysis is needed to help the academic, regulatory and industry partners discover what inputs, outputs and processes in pork harvest facilities are crucial to understand. This work, when completed, enables all involved to generate new ideas regarding ASFv prevention and control, design subsequent experiments and further validate their findings.

The work is continuing with industry collaborators in finalizing risk assessment priorities, but so far the presumed priorities will be some of the pathways in Table 1. Gaps in both inputs and outputs create concern for harvest facilities as they expose areas where ASFv can enter and spread. The aim is to have additional projects specifically on these areas of focus for full risk assessment development. That work would include more in depth analysis of the pathways, and collaboration with industry partners to develop feasible mitigations and uniform, science-based guidance to support the continued operation of harvest facilities in the event of an ASF outbreak in the United States.

Together, pork producers, pork processors, swine veterinarians, state animal health officials, federal regulatory agents and the scientists in industry and academia can form public-private partnerships and workgroups to provide scientific information upon which the U.S. swine industry can prevent ASFv or maintain a semblance of business continuity and remain sustainable during an ASFv outbreak. This takes hard work if the information is going to be thorough and comprehensive. Despite not being a silver bullet, this proactive approach should help keep nightmarish thoughts of ASFv away and help us look forward to Thanksgiving.

Source: Cesar Corzo, Marie Culhane, Carol Cardona and Timothy Goldsmith, who are solely responsible for the information provided, and wholly owns the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)