Are we ready for the next foreign animal disease? Part 3

Every single one of the 849 breeding herd sites responded that trailers are washed and sanitized after every load.

May 25, 2023

The US Swine Health Improvement Plan is a collaborative effort between industry, state and federal entities modeled after the National Poultry Improvement Plan, but is specifically organized to meet the unique needs and challenges of the U.S. swine industry. In an effort to understand the current status of biosecurity practices being implemented in the U.S. swine industry, all producers enrolling sites with US SHIP are asked to complete a biosecurity survey. As of January 2023, 7,902 individual sites (6,784 Growing pig, 849 Breeding herd, 110 Small holding, 58 Non-commercial, 50 Boar stud, 33 Farrow-to-feeder/finish, and 18 packing plants) in 31 states have responded to the survey. This represents 52% of the U.S. breeding herd and 44% of the U.S. growing pig herd inventory.

This article will present trailer washing and Secure Pork Supply Plans survey results. It will also bring a perspective of the benefits that US SHIP can provide for the swine industry, the importance of stakeholder involvement. According to the survey, many producers are already implementing the practices that make up the current standards and participating in the program will not be a burdensome task for producers.

Much of the discussion and focus of these articles has been on African swine fever and the ASF virus. While we have known about ASFV since its discovery in 1921, it has never been as close to the United States as it is now. In 2021 it was discovered in the Dominican Republic, 72 miles from Puerto Rico. Introduction of ASF into the United States will dramatically impact swine movement, trade and pork price. A recent article describes how the impact of ASF in China increasing retail pork prices by 40%, and also increased prices of beef and poultry by 20% and 15% respectively.1

Trailer wash

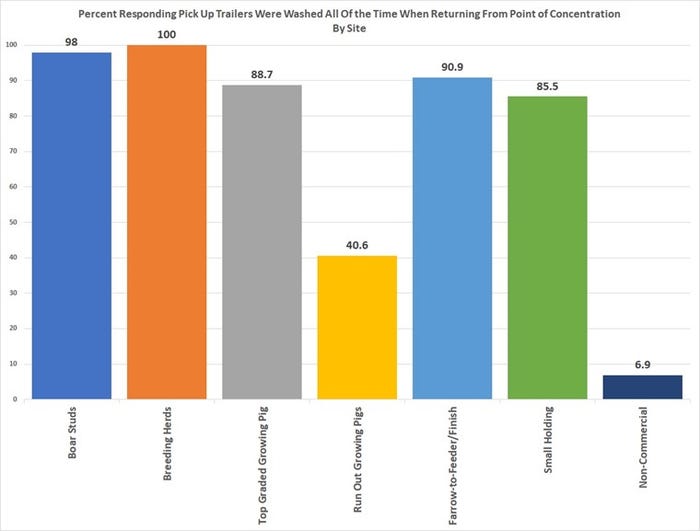

The ASFV can survive 100 days in manure, and it only takes a small amount of manure to harbor a lot of the virus.2 In the biosecurity survey, participants were asked how often the trailers used to transport animals were washed and disinfected after returning from a point of concentration. Every single one of the 849 breeding herd sites responded that trailers are washed and sanitized after every load. Boar stud sites were close behind with 98% of trailers been washed and sanitized after every load. Farrow-to-feeder and small holding sites were both above 85%. Answers for over 1,700 sites mentioned that they either rarely or never clean trailers or they don’t know if they do. See Figure 1.

On the other hand, almost 46% of the run out loads in growing sites are not washed every load when returning from terminal points of concentration, which is a major risk factor for indirectly recirculating, amplifying, and broadly distributing disease among these sites, thus also increasing the risk of contamination to nearby breeding herds or boar studs. In fact, a pattern of increased detection of pathogens such as porcine reproductive and respiratory syndrome in growing sites that precedes the increased detection in breeding herds was reported3, echoing the importance of enhancing the biosecurity in growing sites to prevent regional spreading to other type of swine farms.

Cleaning and disinfecting movement trailers with an APHIS-approved disinfectant, and giving the disinfectant the necessary time to work (contact time) is an effective way to decrease the chances that you are bringing diseases into or out of your facility. By increasing the number of trailers that are properly cleaned and sanitized, we could potentially reduce the chances of a disease outbreak spreading across the production chain.

Secure Pork Supply Plan

As was mentioned earlier, if ASF is introduced to the U.S., the USDA, through memorandums of agreement with government, state and local agencies, and under international trade agreements, would issue an immediate 72-hour movement stand still, i.e., all movement on all live swine and semen would immediately stop. This would affect nearly 1 million pigs being transported daily. Almost all pork exports would also be immediately halted.4

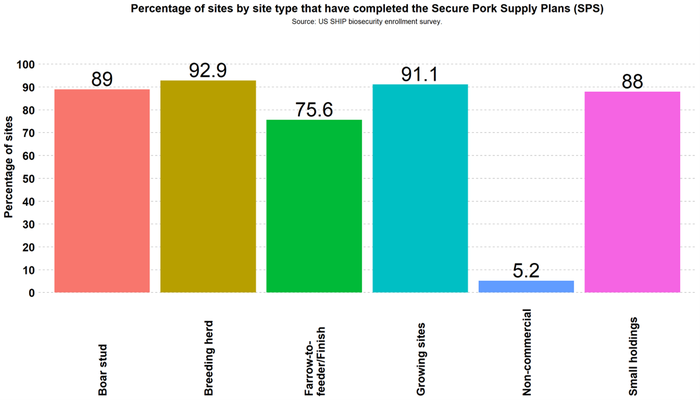

The SPS is a way to prepare before the introduction of a FAD to create credible, provable disease-free zones. These disease-free zones could be leveraged through international trade agreements to support the continuity of business. If we are able to prove that these pigs and pig products come from a disease-free area, our trade partners are more likely to buy pork derived products. Figure 2 shows that a large proportion of survey respondents already have an SPS plan. Due to the perceived importance of the SPS in helping for disease preparedness during 2022 US SHIP House of Delegates a new standard was approved by the body of delegates stating that all boar stud, breeding herd, farrow to feeder, farrow to finish and growing sites shall have a SPS in place.

Creating an SPS plan includes:

Receiving a National Premises Identification Number (PIN) from your state animal health official.

Writing an enhanced, site-specific biosecurity plan.

Monitoring for signs of FAD.

Keeping movement records of animals, people and equipment.

More information about SPS can be found here.

Many of the US SHIP's program requirements are in line with SPS and Pork Quality Assurance Plus recommendations. A list of US SHIP program requirements can be found on the US SHIP project website.

In previous articles we have discussed US SHIP's efforts to create a "national playbook" of technical standards associated with biosecurity, traceability and sampling/testing, which can be used for Foreign Animal Disease preparedness and prevention. Those articles can be found here and here.

Through this series of articles, we have discussed the findings of the biosecurity survey administered to US SHIP enrollees. While capturing a large percentage of the swine population, the survey may not truly represent the swine industry as a whole. Those participating in US SHIP in its early stages represent a segment of the swine industry who are actively preparing to combat FAD. Many stakeholders are unaware of the benefits of US SHIP or are wary of introducing more requirements into their operation. We need you.

The 2023 US SHIP House of Delegates is scheduled for Sept. 5 to 7 in Bloomington, Minnesota. Get in contact with your official state agency contacts and state pork associations to get involved and be part of the decision-making process. Make sure you have a voice in the future of US SHIP. US SHIP works through partnerships with industry and government. To find out how you can participate and help protect the swine industry, visit the project website and talk with your official state agency.

References

Acosta, A., Lloyd, T., McCorriston, S., & Lan, H. (2022). The Ripple Effect of Animal Disease Outbreaks on the Food System: The Case of African Swine Fever on the Chinese Pork Market. Social Science Research Network. https://doi.org/10.2139/ssrn.4251029

Sanchez-Vizcaino, J. M., Martinez-Lopez, B., Martinez-Aviles, M., Martins, C., Boinas, F., Vial, L., ... & Roger, F. (2009). SCIENTIFIC REPORT submitted to EFSA Prepared by Sanchez-Vizcaino. JM, Martinez-Lopez, B., Martinez-Aviles, M., Martins, C., Boinas, F., Vial, L., Michaud, V., Jori, F., Etter, E., Albina, E. and Roger, F, 1-141.

Trevisan, G., Linhares, L.C.M., Crim, B., Dubey, P., Schwartz, K.J., Burrough, E.R., Wang, C., Main, R.G., Sundberg, P., Thurn, M., Lages, P.T.F., Corzo, C.A., Torrison, J., Henningson, J., Herrman, E., Hanzlicek, G.A., Raghavan, R., Marthaler, D., Greseth, J., Clement, T., Christopher-Hennings, J., Muscatello, D., Linhares, D.C.L., 2020. Prediction of seasonal patterns of porcine reproductive and respiratory syndrome virus RNA detection in the U.S. swine industry.

USDA. (2020, April). ASF Response Plan: The Red Book. https://www.aphis.usda.gov/animal_health/emergency_management/downloads/asf-responseplan.pdf

You May Also Like