MUDA, MURA, MURI: LEAN means more than just meat

Our benchmarking programs in the swine industry show significant opportunities in all areas of production.

February 8, 2023

Biological manufacturing is the present reality of pig production, no matter the size of the farm. The predicted increase in the global population by 2050 has fueled the need for food production to scale. However, recent United Nations data suggest population growth may stagnate or decline. (Source: United Nations)

This prediction raises interesting implications for our industry and its footprint of protein production globally. But it also adds more risk to an already tenuous low-margin business where the cost of production and efficiency is everything. The more things change, the more they stay the same.

So, what is next? How do we meet these challenges in a sustainable way for our businesses?

Production efficiency still has huge opportunities for improvement. At the Iowa Pork Congress, I met a producer who mentioned wean-to-market performance is worse today than three years ago, primarily mortality. He felt the industry is regressing. How do we attack this problem of efficiency regression?

LEAN is more than just meat. Taiichi Ohno of Japan is considered one of the founding fathers of LEAN manufacturing. During his quest for improved efficiency, Ohno identified three major barriers that negatively influence a company's work processes: Muda (wasteful activities), Muri (overburdened) and Mura (unevenness).

Our benchmarking programs in the swine industry show significant opportunities in all areas of production. This variation will become mission-critical to define, measure and remove waste if we are to remain competitive in an unpredictable global protein economy. Furthermore, technology will play a critical role in this process.

MUDA = waste. The necessity of a data capture framework that allows visibility to MUDA will be crucial to driving out waste in the production process. Real-time efficiency index and performance scoring will be key differentiators in reducing waste and decreasing the cost of production.

The seven wastes of LEAN:

Transportation

Inventory

Motion

Waiting

Overproduction

Over-processing

Defects

Here are a few examples of LEAN thinking applied.

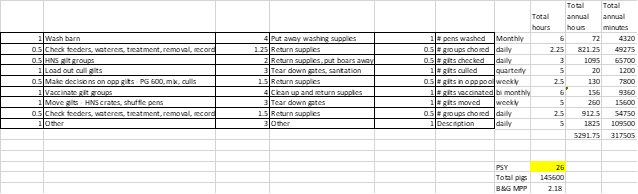

Motion and Waiting: Each stage of the production system can apply MUDA. For example, in our assessment of labor in a 10,000 sow system, we broke down the processes to look at gilt development unit contribution to minutes per pig (MPP). 2.18 MPP is allocated from GDU. This contributes 7.5% of the time to the production of the weaned pig. The total minutes per pig = 29.2, which is excessive. But now we know and can build a process around driving out motion and waiting.

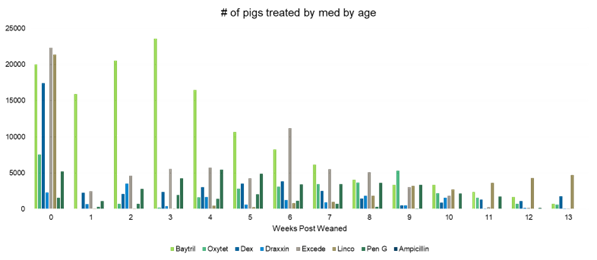

Overprocessing: Another example is the pig treatment patterns we have identified in our wean-to-market SmartAction Framework. The inconsistency in medications, dosage and caretaker behavior patterns is becoming apparent. Measuring overprocessing is the first step to standardizing the process around the correct dose and the right time. Capturing data in real-time allows for earlier intervention.

These are just a few examples of how biological manufacturing fits into the continuous improvement process. Technology plays a huge role in enabling caretakers, production managers, supervisors and C-Suite decision makers to play an active role in making changes to production execution that decrease costs and increase the opportunity for additional margin. Thus, you have MUDA.

LEAN is more than meat. It is the future of protein production in the sense that reducing variation, rooting out waste and increasing pounds produced through internal changes in the process. Having a framework to measure data in real-time and apply MUDA is crucial to improvement.

Summit SmartFarms is devoted to creating irresistible places to work in agriculture by simplifying the complex and equipping people to optimize performance through technology. If you would like to learn more about how Summit SmartFarms can help your organization, you can email Jon Hoek.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)