Batch farrowing may not produce the most piglets from your farrowing house, but it may produce the lowest cost of pork from your overall production system.

Population disease management for endemic pathogens requires the successful transition of individuals within the population from “susceptible” to “infected” and eventually “resistant” status. In populations with well controlled endemic disease, the population moves as a collective group of individuals through the “infected” status with minimal clinical signs, minimal performance impacts and minimal duration of infection.

In populations with poorly controlled endemic disease, subpopulations of individuals exist in “susceptible,” “infected” and “resistant” categories simultaneously. The subpopulation of “susceptible” individuals serve as a reservoir of naïve hosts for the pathogen to replicate within. The population of “infected” individuals serves as a reservoir of active pathogen replication, sustaining infectious pathogen in the population. The population of “resistant” individuals may end up being overwhelmed by the high levels of pathogen in the environment, reentering the “infected” category as their immunity wanes.

Principles of All-In-All-Out production were built with population disease management in mind. We place a group of contemporary animals all with the same individual health status and transition them from “infected” to “resistant,” minimizing disease impacts through appropriate vaccination and medication strategies. This approach works well in growing pig populations, but its application in piglet populations at breed-to-wean farms is often overlooked. Breed-to-wean farms commonly operate breeding barns on a “continuous breeding” cycle which results in a “continuous farrowing” cycle. When farms farrow every day, by definition we have “susceptible,” “infected” and “resistant” individuals within the BTW piglet population, a recipe for poorly controlled endemic disease.

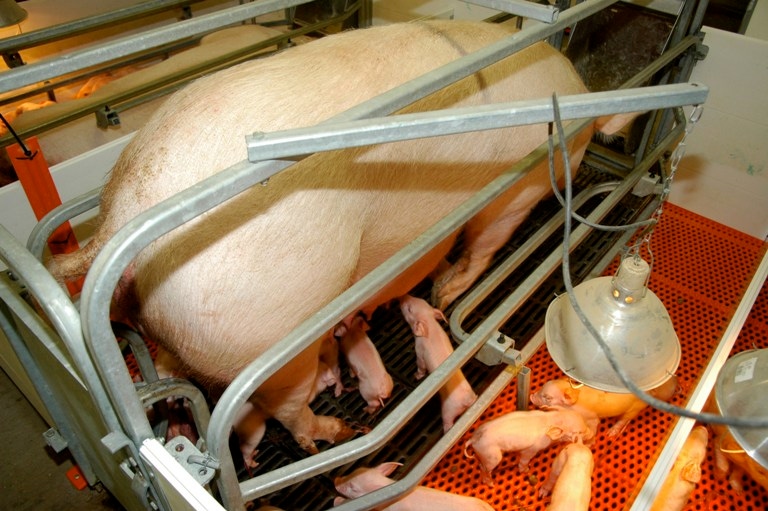

Continuous breeding and farrowing were facilitated by the industry transition to multi-site production several decades ago. On farrow-to-finish farms, nursery space was always a bottleneck that prevented continuous weaning which prevented continuous breeding which prevented continuous farrowing. As the U.S. industry moved to multi-site production, we were no longer limited by the available nursery space to regularly wean. Producers quickly recognized the value of their new system — breeding and farrowing every day decreases the percentage of time a farrowing crate isn’t being used to lactate a litter of piglets. As such, both throughput (number of farrowings per unit time) and wean age improved in continuous breeding and farrowing BTW farms.

Endemic pathogen challenges have changed dramatically since the transition to multi-site production and continuous farrowing and breeding. Influenza and rotavirus are tremendous examples of pathogens that have evolved from their previously less diverse and pathogenic ancestors. Novel and emerging pathogens such as porcine circovirus type 2, porcine reproductive and respiratory syndrome virus and porcine epidemic diarrhea virus have further challenged endemic disease control.

Simply put, the consequences of poorly controlled endemic disease challenges are much greater in 2018 than they were several decades ago. Batch farrowing remains as a tool for producers currently challenged with poor endemic disease management. Batch farrowing has its negatives — less efficient use of lactation crates, lower wean age, lower throughput (lower pigs per sow per year) and the surges in labor needs during breeding, farrowing and processing all must be considered. The negatives are generally stagnant, their impact was the same several decades ago as it is today. The positives of batch farrowing in terms of improved endemic disease control have grown more valuable with each novel and emerging pathogen challenge. Across the world, producers are asking themselves — even with fewer pigs produced from the farrowing house can I produce more pounds of pork out of my production system utilizing batch farrowing?

There are four common models of batch farrowing: two models that are AIAO in the farrowing house and two models that split the farrowing house into two units. Each model lets the producer choose whether they prefer to take more impact to throughput (less farrowing events per unit time) or wean age (more farrowings but younger wean pigs). There is no single model that is best for all producers, the best model for each producer must be determined independently.

The 5/4 and 4/5 batch models are AIAO models that have five groups of sows farrowing every four weeks or four groups of sows farrowing every five weeks, respectively. The 5/4 model maximizes throughput with a greater sacrifice in wean age. The 4/5 model maximizes wean age with a greater sacrifice to throughput. As both models are AIAO they are generally thought of as creating the greatest health advantage.

The 7/3 and 10/2 batch models split the farrowing house into two units and have seven groups of sows farrowing every three weeks or 10 groups of sows farrowing every two weeks, respectively. The 10/2 model maximizes throughput with a greater sacrifice in wean age. The 7/3 model maximizes wean age with a greater sacrifice to throughput. While this model has two subpopulations in the farrowing house at any given time, its impact on health may or may not be different than the AIAO batch models. For producers with two independent farrowing houses, this model may give the same health advantages as AIAO models with the increased flexibility of more frequent breeding weeks.

Batch farrowing provides unique challenges for producers and veterinarians to overcome. Natural variation in a gilt’s first estrus age requires either the utilization of hormones to place gilts into an appropriate breeding week or a common gilt pool for multiple farms. Recycles similarly have a natural variation in their recycle dates and must be transferred to another breeding group using hormones or simply culled at the time of recycle identification, increasing the farm’s annual gilt replacement rate. Nurse sows are challenging to create in a batch system and consideration should be given to the use of supplemental milk decks as a method of creating nurse sows. Farrowing and breeding dates create a surge in labor needs relative to continuous production. Batch farms must shift labor from other areas of the farm if they are unable to rotate their best labor across multiple facilities. There is an important theme to recognize when managing batch-specific challenges, farms who can share common sources of gilts and/or employees have a unique advantage due to their ability to apply these resources to the farm currently needing animals ready to breed or employees with a specific skill set.

The importance of farrowing house sanitation in a batch production system cannot be underestimated. While there is a tremendous amount of work to do, labor to wash the farrowing house is generally not a rate limiting resource. In the days immediately following weaning, there are no piglets to care for, no sows to farrow and minimal if any breeding. As such, the time required to clean, disinfect and set up the farrowing house for the next batch is entirely regulated by the quality and quantity of washing equipment at the farm. Producers should aim to run multiple power washers simultaneously and stagger employee start/stop times to allow as close to 24-hour washing as possible. Routine maintenance checks of the washing equipment and supplies should occur five to seven days prior to weaning, allowing any needed maintenance or supplies to be in place and all systems functional the day of weaning. The faster we wash and reload the farrowing house, the more we maximize wean age and throughput, minimizing the inherent negative sow farm impacts.

In summary, batch farrowing improves endemic disease control by taking groups of piglets through the infection and immune development process as a group, minimizing the duration and performance consequences associated with infection. In addition to improved endemic disease control, batch farrowing also more easily facilitates epidemic disease elimination, particularly when combined with medicated early weaning/segregated early weaning programs. Farms that have the opportunity to share gilt sources and/or rotate specialized labor have a significant advantage toward overcoming the unique challenges associated with batch farrowing.

To minimize the batch impact on wean age and throughput, producers should invest in additional power washing equipment and ensure this equipment is functional prior to weaning every batch. Batch farrowing has potential costs to consider including the initial conversion from continuous farrowing, increased non-productive days, decreased wean age, decreased litters farrowed and increased hormone usage.

Producers should evaluate their projected costs and revenues under both batch and continuous production models. Batch farrowing may not produce the most piglets from your farrowing house, but it may produce the lowest cost of pork from your overall production system.

About the Author(s)

You May Also Like