Regulations today call for an integrated, close relationship between the producer, veterinarian and the feed supplier.

June 23, 2017

By Ralph D. Wilson, Pharmgate Animal Health

Since the first of the year, feed medications that were once readily available over-the-counter to treat swine diseases, now require the diagnosis and direction of a veterinarian. A stumbling block in the effort to fill out the Veterinary Feed Directive forms correctly is the space for listing the drug level as grams per ton. Additionally, estimating the amount of ration for the treatment period is troublesome. Regulations today call for an integrated, close relationship between the producer, veterinarian and the feed supplier. A great deal of information is required to have precise estimates of the modifiers of feed intake, and hence drug intake. This column will attempt to show examples of calculating drug levels in different scenarios and estimating the amount of feed required.

The proper dosage should be paramount in our efforts to treat animals in our care. Under-dosing of drugs could result in improper treatment, continued sickness and even death of the patient. Over-dosing of drugs is irresponsible and could lead to residue in the food we are producing. Food and Drug Administration Guidance for Industry 233 states that the VFD form will have a space for the veterinarian to populate with the drug level in the feed in “Grams per Ton.” The relative importance of drug level has arisen from the many decades of manufacture and floor-stocking of medicated feeds. Samples could be taken at inspection time and compliance could be determined, so as to ensure fairness to purchasers and safety from over-dosing mistakes. The trouble at the farm is that drug level does not ensure proper dosing unless the modifiers of feed intake are conveyed from the pork producer to the veterinarian of record and coordinated with the feed supplier.

The veterinarian has a very difficult time in filling out the drug level portion of the VFD form, mostly because he/she is working with insufficient information from the producer and feed supplier. The VFD is much easier when the veterinarian is working in concert with the producer and feed supplier. In the process of establishing the Veterinary-Client-Patient-Relationship, communication lacks as to the modifiers of feed intake. The VFD form only calls for the estimated number of animals, but the veterinarian must also know the weight of the animals and the feed intake. Now, more than ever before, the veterinarian, the producer and the feed supplier must communicate and work together. When all parties work in concert, the VFD is much easier and more likely correct. When the veterinarian is left to assume/guess the feed intake, the drug level is data left to interpretation and judgement as to correctness by an outside inspector. This is a major point to cause a veterinarian concern and give him/her cause to prefer alternative treatment methods.

The modifiers of intake are impossible to know without a great deal of prior information from all concerned. The producer, feed supplier and their nutritionist must help the veterinarian with all this information, or the intakes will be based solely on generalized assumptions. Modifiers of intake include energy density, sex, stage of production, age, temperature, feeder space, genetics, access to water, feeder adjustment and activity, just to name a few. If these factors are known beforehand and are of sufficient magnitude, they must be included in the calculations going into grams per ton.

Examples of calculations

The feed medication claims and dosages for swine were derived from trials with ad libitum feeding. Knowing this should give the veterinarian confidence in this method of disease treatment. Natural variation in intakes should not give the veterinarian-of-record concern as the same occurred in the proofing trials. That is unless the animals are to be limit fed, as in sows, or the modifiers of intake are sufficiently large. It will always be easier when the VFD information is populated with the consensus of the veterinarian, the producer and the feed supplier.

There are examples of a single drug level appearing on the labels of MFA products for swine. An example would be Aivlosin 17% which has a single inclusion rate of 0.5 pound per ton of feed resulting in 38.6 grams per ton. Another would be the Chlortetracycline/Sulfamethazine combination products which are added to obtain a set 100 grams per ton of CTC and 100 grams per ton of Sulfamethazine. Additionally, there are chlortetracycline products which are indicated to be fed at 400 grams per ton. The VFDs for these swine indications are relatively easy to populate the drug level space.

MFA products which are intended to be fed at a rate per unit of bodyweight involve a bit more effort. Even in this case the math is easy and assumptions fit a great many situations. Let’s show an example.

Example of 80-pound grower pigs being treated with Chlortetracycline at the rate of 10 mg/lb. wt./day.

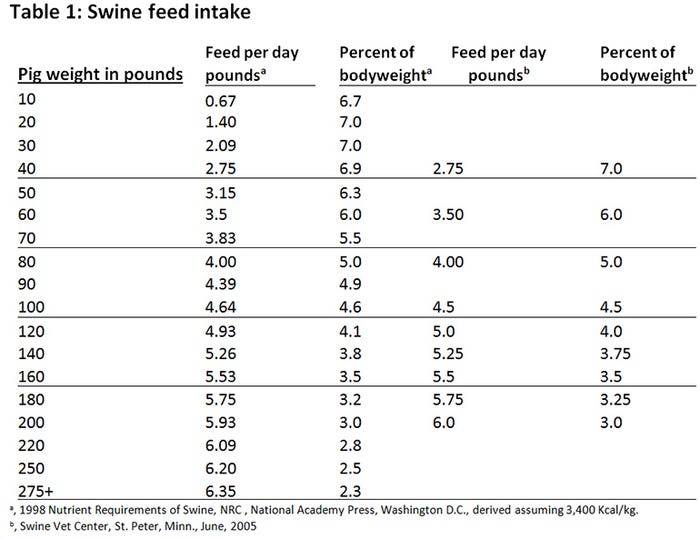

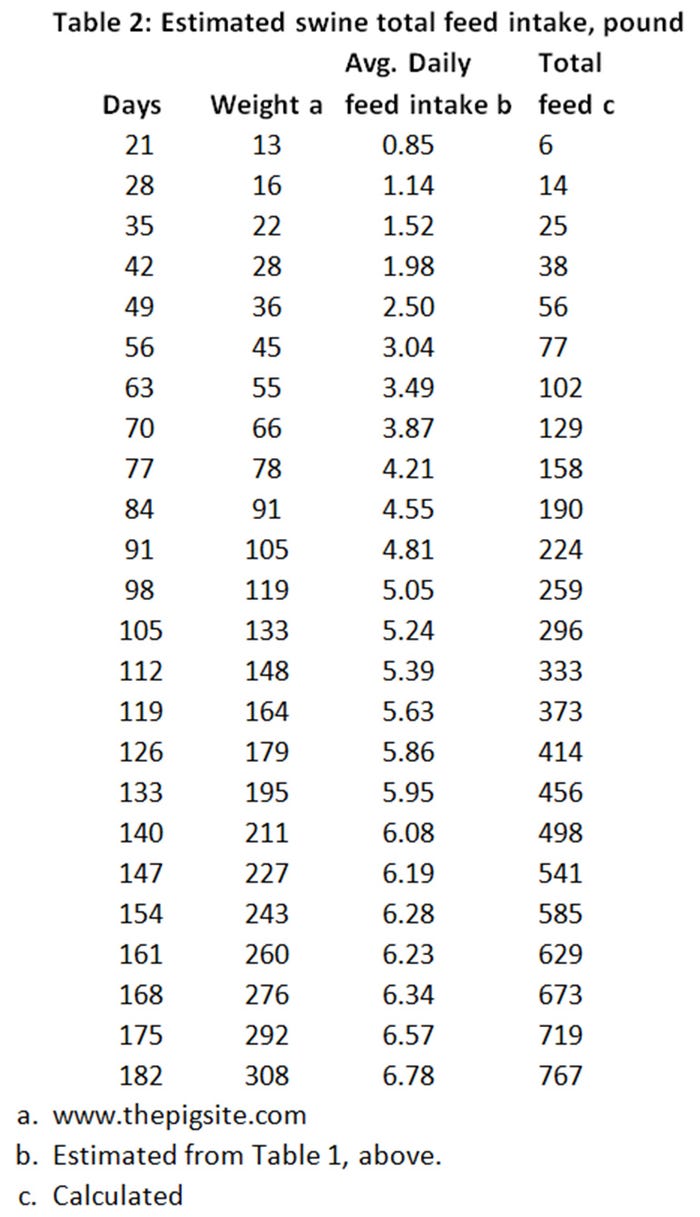

From Table 2, we find that 80-pound pigs eat 4.0 pounds of feed daily on full feed. The 80-pound pig needs 800 milligrams per day of CTC. (80 lb. X 10 mg/lb. wt./day = 800 mg/day.)

2,000 divided by 4.0 lb. = 500 daily feedings times 800 mg/day = 400,000 mg/T., or 400 g/T.

Or, alternatively, 80 lb. times 10 mg/lb. = 800 mg; divided by 4 lb. feed = 200 mg/lb. or 400 g/T in the feed

In this case the VFD would be populated with 400 grams per ton, with feeding directions that the 80-pound average pigs be full fed with the intended average intake of 4.0 pounds to provide 10 mg/lb. wt./day.

A great many typical situations for growing hogs calculate to 400 grams per ton. It is when you start to incorporate intake modifiers into the situation that you arrive at different answers. Gilts eat less than barrows. Warm temperatures reduce intake. Added fats reduce voluntary intake. Limited water access reduces intake. There are genetic groups which indeed do eat smaller meals and result in improved feed efficiency and leaner gain.

Ractopamine for swine is estimated to reduce feed intakes by 6%. The major point being that the veterinarian will need to be alerted to these intake modifiers if they are going to be used in the calculations for grams per ton.

There are examples of combination claims in which one drug is included at a set rate while the other is indicated at rates based on weight. Such is the example of the combination claim of Tiamulin and Chlortetracycline. The Tiamulin is to be added at 35 grams per ton and the Chlortetracycline is recommended at 400 grams per ton, but actually is flexible with the 10 milligrams per pound of bodyweight per day indication.

Example of limit feeding 450-pound sows to a feed intake of 4.5 pounds per head with a chlortetracycline pulse at 10 mg/lb. wt./day.

2,000 lb. divided by 4.5 lb. = 444 feedings times 4,500 mg/head (450 lb. X 10 mg/lb. wt./day = 4,500 mg/day) = 1,998,000 mg/T., or 1,998 g/T. (This situation would be rounded to 2,000 g/T in a practical situation.)

Or, alternatively, 450 lb. times 10 mg/lb. = 4,500 mg; divided by 4.5 lb. feed = 1,000 mg/lb., or 2,000 g/T in the feed. In this case, the VFD would be populated with 2,000 g/T, with feeding directions that the average 450-pound sow should be limit fed 4.5 pounds of complete medicated feed daily.

How much feed is needed?

The feed supplier and producer now need to determine how much feed is needed for the indicated duration of treatment. The same care should be given to determining the amount of feed to be produced as was given to calculating the grams per ton. Producing and presenting too little feed could lead to insufficient duration of treatment of the disease and poor results. Too much feed means the duration of treatment will proceed too long and is not permitted by inspectors. State inspectors have stated that excess feed would have to be manually removed from tanks and feeders. While incredibly unpractical, it has been said that it would be required. The prospect of this has given pause to veterinarians and producers, causing them to choose alternative methods of treatment.

Estimating the amount of feed for the duration of treatment can be successfully accomplished. Some MFA products are indicated to be fed for set time periods, like feed “as the sole ration for 14 days”. Others state ranges like, “Feed continuously for not more than 14 days” or “Feed continuously for 7-14 days.” The MFAs with feed duration ranges make the decision for the amount of ration to be produced more flexible. Still, there is a desire to manufacture a proper amount to achieve desirable treatment results.

Example of feed required for 50 head of 120-pound pigs for 14 days

There is more than one way to accomplish this task.

First, using Table 1, the estimated intake for a 120-pound pig is 4.93 pounds. 14 days times 4.93 pounds equals 69 pounds times 50 head equals 3,450 pounds. This would be an under-estimate since it would not account for pig growth and increased intake over the 14 days.

Another estimate, using Table 2, would be to use the difference in total feed intake from the 98-day old pig weighing 119 pounds (259 pounds) from the total feed intake 14 days later (333 pounds). 333 pounds minus 259 pounds equals 74 pounds times 50 head equals 3,700 pounds. This estimate should be more accurate as it takes into account that feed intakes increase as the pigs grow over the 14 days of treatment.

Another method would be to use an estimated average intake over the period. Table 2 says that the pig would be 148 pounds after 14 days of growth. Looking at Table 1 again, the 148-pound pig would be eating a calculated 5.38 pounds. The average intake over the 14-day period would be ((4.93 + 5.38)/2= 5.155 pounds).

5.155 times 14 days equals 72.17 pounds times 50 head equals 3,608.5 pounds. Or, one could use the estimated intake at the midpoint of 105 days in Table 2, which is 5.24 pounds. The calculated feed needs would be 3,668 pounds. This estimate using average intake over the period would be a conservative amount but more accurate than just using the starting level of intake.

The producer and feed manufacturer would choose from these estimates which gave them the greatest confidence in providing the proper length of treatment.

The issue of mixer batch size is a problem that may not have easy answers. Mixers do the best job of mixing when filled to the designed proper level. However, this will rarely match precisely the estimated amount needed to provide the desired length of treatment. Rounding up too far to match mixer batch sizes can lead to left over medicated ration in the feeders and confrontation with inspectors.

Filling the space on VFD forms with the proper grams per ton is not an insurmountable task. Far from it. Then too, determining the exact amount of feed to produce is not without issues. However, make no mistake, it becomes an easier task when information from all parties — the veterinarian, the producer and the feed supplier — work together to improve the accuracy of the data and strengthen the VCPR.

Aivlosin is a registered trademark of ECO Animal Health Inc.

You May Also Like