A $5 million grant from the USDA’s National Institute of Food and Agriculture was devoted exclusively to advancing the science and practical knowledge of feed efficiency in swine. The grant funded an International Symposium on Feed Efficiency in Swine to establish the current state of the art of feed efficiency.

February 1, 2012

An international team of swine nutrition specialists and related scientists gathered in Omaha, NE, on Nov. 8-9 to take a hard look at the many challenges and opportunities associated with the efficient conversion of feed into lean pork.

The International Symposium on Feed Efficiency in Swine was coordinated by Iowa State University (ISU) and Kansas State University (KSU). The goal of the two-day program was to establish the current state of the art of feed efficiency — “what we know and what we need to know,” explains John Patience, ISU swine nutritionist.

The impetus for the conference is a $5 million grant from the USDA’s National Institute of Food and Agriculture, devoted exclusively to advancing the science and practical knowledge of feed efficiency in swine, Patience says. Several ISU scientists will join researchers from Kansas State University, the USDA Agricultural Research Service National Laboratory for Agriculture and the Environment, the Australian Pork Cooperative Research Centre, the Institut National de la Recherche Agronomique in France and the University of Saskatchewan in Canada. Twenty-one scientists are involved in a multidisciplinary approach to a five-year project coordinated by Patience. Two-thirds of the funds are to be directed to research and one-third to Extension, the conference being the first step in sharing existing knowledge and the knowledge to be gained.

Fifteen presentations covered all manner of measuring and managing feed conversion in swine — from the impact of genetic selection, herd health and environmental influences to feed form, physiology of digestion, and the standard adjustments needed to effectively calculate feed efficiency at various stages of production.

Setting the Stage

As feed costs rise, interest in feed efficiency logically follows. It stands to reason, then, that as the price of corn doubled in the span of about two years, the nation’s largest pork producer — Smithfield Foods — was readily crunching the cost of production numbers on the 17 million hogs raised annually.

“A 25-cent/bushel change in corn price and all of the associated feed ingredients that comes with that — since everything hedges to corn — changes our cost of production about $1.60/cwt.,” explains Steve Pollmann, president of Murphy-Brown western operations, a pork-production arm of Smithfield Foods.

A swine nutritionist by training, Pollmann opened the conference program by citing AgriStats data representing about 35% of U.S. pork production. Feed costs represented about 60% of the cost of production in May 2009, but by August 2011, that figure had grown to 70%. Extrapolating the cost-of-production increase to a sensitivity analysis used by Smithfield Foods, Pollmann says a 1% change in feed efficiency is equivalent to about a $31 million shift in cost of production for the U.S. pork industry.

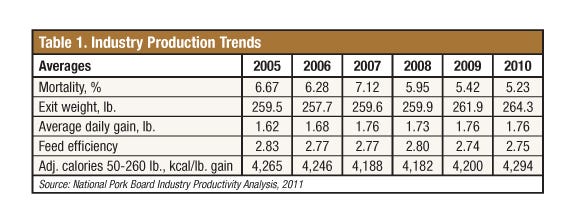

Furthermore, a current National Pork Board production trend analysis shows feed efficiency has changed very little in the past six years (Table 1). “The data suggests that we have had a lot of mortality in the U.S. pork industry the last six years, but it is getting better at a rate of about 3% per year. Market weights are increasing at the rate of 1 lb./year and average daily gain is also improving. Feed efficiency has changed only slightly, and caloric feed efficiency, measured in kilocalories/lb. of gain, has changed very little,” he adds.

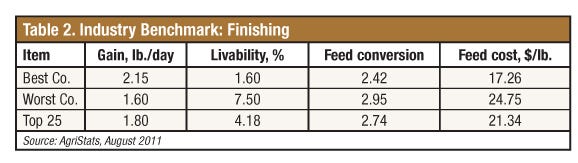

“Still, it’s amazing to see the amount of variation that exists from the top to bottom in our industry,” he continues, citing finishing data summarized in August 2011 (Table 2). Pitting the “best” companies against the “worst” in the dataset points to a 40% difference in average daily gain, 53% difference in feed conversion, 6% difference in livability and $7.50/cwt. difference in feed costs/lb. of gain. “That’s a 43% range, top-to-bottom, an incredible variation. Somebody’s not going to survive at those kinds of rates,” he notes.

“When we look at feed efficiency — the intent of this conference — it is an important metric, but it is not a lead indicator (of performance), in my opinion. It is a ratio that can be very confusing,” Pollmann continues. “We have to be very careful as we strive to benchmark feed efficiency because it requires extensive standardization of variables, such as the nutrient density and physical form of a diet, pig placement and market weights, mortality rates and whether Paylean (Elanco Animal Health) was fed.

“Feed efficiency is an outcome. Be careful with it,” he urges. “Do not use it as a lead indicator of performance, because it requires a lot of standardization.” Examples of feed efficiency adjustmentswill appear in a host of related articles entitled, "Gettng a Handle on Whole-Herd Feed Efficiency," "Small Details Offer Big Feed Savings," and Focusing on Pigs' True Amino Acid Needs."

You May Also Like