Blast Chilling Inhibits Loin Chop Tenderness

December 22, 2011

Blast Chilling Inhibits Loin Chop Tenderness

Blast chilling systems, in which dressed pork carcasses pass through freeze tunnels of -15° F or colder for 1-3 hours after harvest, are used to increase packing plant throughput, enhance food safety and improve meat quality, particularly the water-holding capacity of muscles from stress-susceptible hogs.

Work at the U.S. Department of Agriculture’s Meat Animal Research Center (MARC) shows that differences in chilling systems among U.S. pork packing plants can have a strong influence on pork chop tenderness. Blast chilling results in a 13-fold increase in the frequency of loins with unacceptably tough chops. MARC is operated at Clay Center, NE, by USDA’s Agricultural Research Service.

The MARC study was designed to provide a large-scale objective comparison of pork loin meat tenderness and other meat quality traits between packing plants that utilize different stunning methods and carcass chilling rates.

For two days, hogs from a single terminal crossbred line were sourced from a single finishing barn. Three truckloads were delivered to one of three packing plants. Plant A utilized CO2 stunning and conventional spray chilling. Plant B utilized CO2 stunning and blast chilling. Plant C utilized electrical stunning and blast chilling. A boneless, vacuum-packaged loin was obtained from the left side of the carcasses.

Hot carcass weight, loin muscle depth and loin muscle intramuscular fat were similar among hogs delivered to the three plants, as expected.

However, by one hour after the carcasses exited the harvest floor, the average deep loin muscle temperature was more than 50° F higher for Plant A than Plants B and C. And deep loin muscle temperature continued to be more than 50° F higher for Plant A until six hours postmortem than for Plants B and C, respectively.

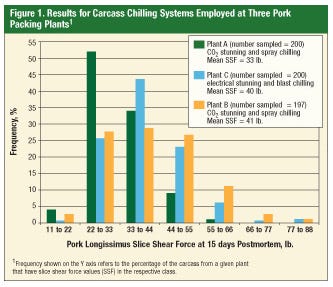

Moreover, both plants that utilized blast chilling produced loins with higher loin muscle slice shear force at 15 days postmortem than did the plant that utilized conventional spray chilling. Slice shear force is the amount of force necessary to shear across muscle fibers.

The frequency of loins with excessively high loin muscle slice shear force values was much greater for Plant B than it was for Plant A (14.7% vs. 1%). Researchers have applied for additional funding from the National Pork Board to understand the mechanism of how some carcasses can produce tender loins when blast chilled and others do not.

Among all of the traits studied, including visual and instrumental evaluations of loin muscle, muscle color, ultimate pH, marbling score and lean color stability, the only difference between Plant A with spray chilling and Plants B and C with blast chilling was that purge loss from Day 1 to 14 of vacuum-packaged storage was higher for the plants with blast chilling. That means there were no loin quality advantages detected for blast chilling.

Regardless of chilling method, CO2 stunning produced darker loin muscle color and higher loin muscle water-holding capacity than did electrical stunning.

Results for the three plants can be found in Figure 1.

MARC researchers note that the findings should be viewed in the context that tenderness is one of many traits affected by chilling systems, and other factors, including food safety and profitability of pork production, must be considered.

Further research is needed to determine temperature and pH profiles for optimal pork quality. Pork Checkoff provided partial funding for this research.

Researchers: S.D. Shackelford, D.A. King and T.L. Wheeler, U.S. Meat Animal Research Center. For more information, contact Shackelford by phone (402) 762-4223, fax (402) 762-4149 or e-mail: [email protected].

Removing DDGS Improves Belly Firmness

University of Kentucky research indicates that withdrawal of high levels of distiller’s dried grains with solubles (DDGS) in late finishing improves belly firmness. But soft bellies resulting from feeding a high level of DDGS don’t affect slicing bellies or eating quality of bacon.

An experiment was conducted to evaluate the effects of feeding a high level of DDGS to pigs for the entire grow-finish period and to learn if withdrawal of DDGS in late finishing would influence performance, belly firmness, processing of cured bellies and eating quality of bacon.

In the study, 168 crossbred pigs were evaluated in seven treatments: a corn-soybean meal control diet; a similar diet with 45% DDGS fed continuously to the end of the experiment; or three treatments in which the DDGS was removed during the final two, four or six weeks of the trial, followed by feeding of a corn-soybean meal diet. Two other treatments used the same two corn-soybean meal and DDGS diets, but with 5% added tallow. Each treatment was evaluated with six replications of three or five pigs/pen. Three pigs/pen were slaughtered for carcass information.

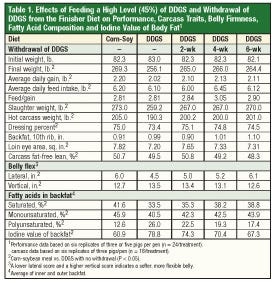

Results for DDGS withdrawal are shown in Table 1, page 28. Average daily gain and average daily feed intake were reduced slightly in pigs fed DDGS continuously, but feed efficiency was not affected. Average daily gain and feed intake improved as DDGS withdrawal time increased. Carcass dressing percentage was reduced by DDGS, and withdrawal of the ethanol byproduct improved dressing percent.

Pork bellies of DDGS-fed pigs were softer, but belly firmness improved as withdrawal time increased. When DDGS was withdrawn for six weeks, the belly flex measurements were the same as for the control pigs.

In other results, the percentage of polyunsaturated fats in the backfat and belly fat increased when DDGS was fed, but the changes moderated the longer DDGS was withdrawn.

Iodine values (IV) rose when pigs were fed DDGS, but values decreased with increased time of withdrawal. The four-week withdrawal time brought IV to near 70, considered ideal, and the two-week withdrawal time brought IV to near 74, considered acceptable. Adding tallow (a harder fat) failed to improve belly firmness or IV.

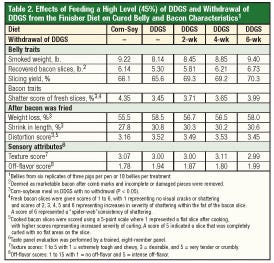

Carcass bellies were processed at a commercial processing plant where slicing yield was determined and fresh bacon slices were scored for shatter. Slices were fried and scored for distortion, cooking loss and shrink, and evaluated by a trained, eight-member sensory panel.

Table 2 shows that feeding DDGS resulted in softer bellies but had no effect on slicing yield of smoked bellies, similar to findings of previous research at the University of Kentucky.

The softer bellies actually produced bacon with improved shatter scores, but after frying there was more weight loss, shrink and greater distortion in bacon from pigs fed DDGS.

The sensory panel found no significant differences in texture or off-flavor in bacon from any of the treatment groups.

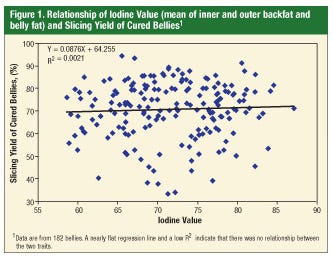

In this study, belly firmness did not correlate with slicing yield of cured bellies, which is in contrast to packing industry observations that soft bellies are difficult to slice and result in less marketable bacon slices.

In further evaluation, slicing efficiency of individual bellies from this study and a previous study were plotted against the IV scores of those same bellies. The belly data illustrates that while slicing efficiency was quite variable, there was no relationship between IV and slicing efficiency (Figure 1).

This study clearly shows that feeding DDGS to finishing pigs increases belly softness, polyunsaturated fatty acid percentages and iodine values of backfat and belly fat.

Belly softness problems and high IV can be overcome by withdrawing DDGS in late finishing. This study, supported in part by the Pork Checkoff, found a two- to four-week withdrawal period produced acceptable iodine values.

Researchers: Miranda Ulery, Gary Cromwell, Gregg Rentfrow and Merlin Lindemann, University of Kentucky. For more information, contact Cromwell at (859) 257-7534 or e-mail: [email protected].

Unsaturated Fat Increases Carcass Fat Iodine Value

Adding fat to pig diets improves performance and feed efficiency. However, adding highly unsaturated fat will result in an increase in the iodine value of carcass fat. Jowl fat has higher iodine values than fat sampled from the belly or from backfat.

Of most concern to pork carcass quality are fats that are termed “unsaturated” or those that are soft or even liquid at room temperature. Corn or soybean oil are highly unsaturated fats. Tallow is a saturated fat (solid at room temperature). Choice white grease, commonly used in pig diets, is intermediate between tallow and corn oil. Distiller’s dried grains with solubles (DDGS) contain 8 to 12% corn oil, which means feeding DDGS to pigs results in the feeding of corn oil, an unsaturated fat.

Measurement of iodine value (IV) is a key issue in the pork industry, as some packers use it as a standard of quality. Yet, research on IV is relatively limited.

The objective of this study was to develop a more comprehensive understanding of how supplemental fat in the diet affects the composition of body fat during finishing and at marketing.

Individually penned pigs were fed one of six treatments: 3% or 6% of either tallow, choice white grease (CWG) or corn oil. A control corn-soy diet with no added fat was also fed.

In analyzing carcass fat samples, it was shown that carcass fat IV was affected by the unsaturation in the fat source. Unlike the other two fat sources studied, the IV produced by corn oil in the diet was affected by inclusion level. Corn oil at 6% had the highest IV at 80, while all other treatments resulted in carcass fat samples with IV under 73.

If we assume that an acceptable IV is 74, then both CWG and tallow can be fed without concern up to 6% of the diet. However, IV for CWG can vary widely; the product used in this experiment had an IV of 66.5, but can be much higher depending on the supplier.

Carcass lipid IV was also affected by sex, with barrows at 69.1 and gilts at 71.5. These results indicate the importance of knowing IV of fat source in the diet and the level at which it is fed. This helps producers determine how much corn oil, fed directly or as DDGS, can be fed while still producing a good-quality carcass.

Average daily gain and gain-to-feed ratio were improved by added fat, reinforcing that increasing diet energy intake will increase barn throughput (Table 1), but highly unsaturated fats will increase carcass fat IV in a dose-dependent manner.

Researchers: Trey Kellner and John F. Patience, Iowa State University. For more information, contact Patience by phone (515) 294-5132, fax (515) 294-1399 or e-mail: [email protected].

You May Also Like