Grinding corn to reduce particle size increases the surface area, allowing more enzymatic activity to occur.

July 8, 2021

Beyond swine nutrition diet and formulation strategies, manufacturing of cereal grains within complete feeds can impact feed efficiency of growing pigs. Grinding corn to reduce particle size increases the surface area, allowing more enzymatic activity to occur, which increases the digestibility of both energy and other nutrients. Research in finishing pigs has shown that reducing corn particle size from 1,000 to 400 microns improves feed efficiency, however, decreasing particle size below 700 microns is not always beneficial. One consequence of reduced particle can be more lesions and greater keratinization of the stomach esophageal region due to the lack of protective mucus in this region. Therefore, the objective of these studies was to determine the effects of reducing ground corn particle size from 900 to 300 microns on nursery and finishing pig growth performance, carcass characteristics, and stomach morphology.

For this research, experiments were conducted with nursery pigs and grow-finish pigs. For the nursery experiment, 360 pigs were used with five pigs per pen and 12 pens per treatment for 35 days. For the finishing experiment, a total of 323 pigs were used in an 83-day trial. Pens of pigs were allotted to 1 of 6 dietary treatments in a randomized complete block design with BW as the blocking factor, with nine pigs per pen and six pens per treatment. On day 79, two pigs per pen were selected and transported to a USDA inspected packing facility for slaughter and to collect stomachs. The stomachs were taken to the K-State veterinary school where a scoring system was used to determine the severity of ulceration and keratinization of the esophageal opening of the stomach. On day 83, the remainder of the pigs were individually weighed and taken to a packing plant for carcass analysis. For both experiments, treatments were arranged in a 2 ft. × 3 ft. factorial with main effects of corn source and ground corn particle size. The ground corn was ground to 900, 600, and 300 microns.

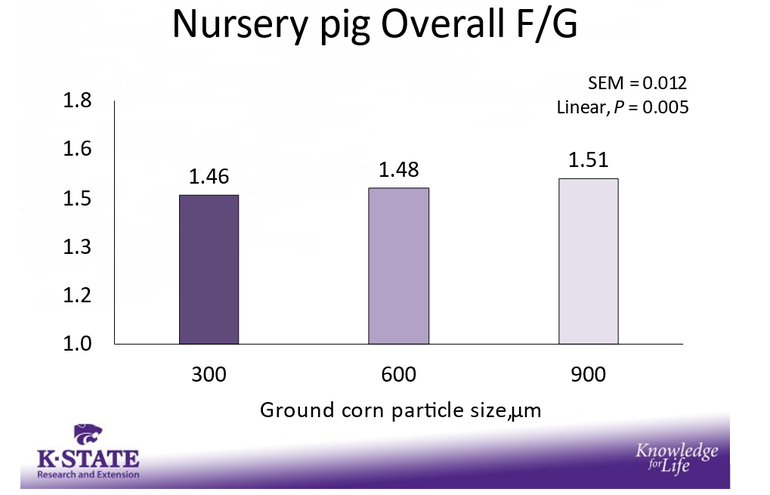

For the nursery experiment, as corn particle size was reduced from 900 to 300-micron, feed efficiency improved. Also, there was a quadratic tendency for an improvement in average daily gain with the best gain achieved in pigs fed corn at 600 microns. This led to a tendency for improved in final body weight for pigs fed 300- and 600-micron ground corn compared to pigs fed ground 900-micron corn.

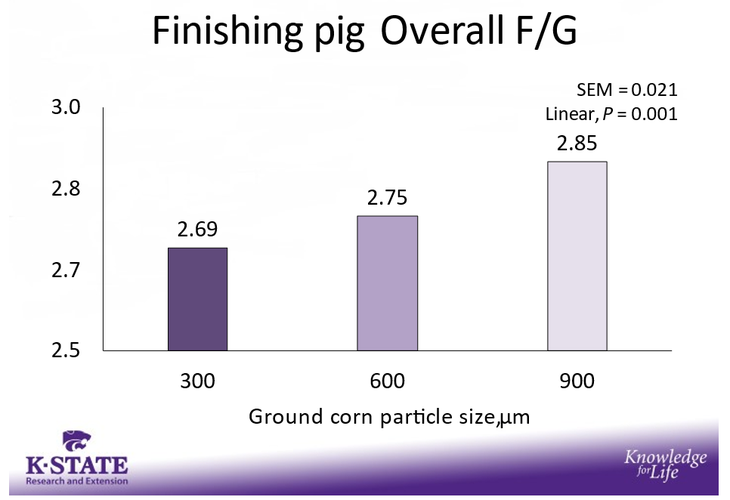

In the grow-finishing study, average daily gain increased as the particle size of the ground corn was reduced from 900 to 300 micron. For feed intake, as particle size of the ground corn was reduced from 900 to 300 micron, we observed a linear decrease in intake. Feed efficiency improved as particle size of the ground corn was reduced from 900 to 300 microns with a 1% improvement in feed efficiency for every 100-micron reduction in ground corn particle size, which is similar to previous research in finishing pigs. There was no difference in ulcer scores between particle size treatments, but as particle size of the ground corn was reduced from 900 micron to 300 micron, we observed an increase in keratinization score. The increase in the keratinization score indicates an increase incidence for keratinization to occur on the esophageal region of the stomach.

In summary, our research has shown that reducing the particle size of the ground corn improves feed efficiency in both nursery and finishing pigs, with a more pronounced response in finishing pigs. This response was generally found by pigs having increased daily gain and reduced feed intake. This data confirms that modern genetic pigs have similar response to corn particle size as data generated over the past several decades evaluating particle size in pigs.

Source: Hadley Williams, Mike Tokach, Joel DeRouchey, Jason Woodworth, Robert Goodband, and Jordan Gebhardt, Kansas State University, who are solely responsible for the information provided, and wholly owns the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset. The opinions of this writer are not necessarily those of Farm Progress/Informa.

You May Also Like