While most of us associate pad systems with evaporative cooling, the same principle applies to the fogger systems found in finishing houses.

July 15, 2022

Sponsored Content

Wetting the pig's skin and allowing it to dry creates evaporation that pulls heat from the pig's body, creating a cooling effect. For direct cooling to work efficiently, the pig's skin should be thoroughly wetted and then allowed to dry completely. The wetting and drying cycle is a critical part of the process. If the pigs are continuously wet, the humidity rises, reducing the amount of cooling by evaporation.

This wetting and drying cycle is key to maximizing the cooling effect. First, set the on-cycle to thoroughly wet the pen area, usually two to four minutes. Next, shut the fogger system off, and note how long it takes for the pen and pigs to dry off completely. This period becomes the off-cycle on the controller. The off time will vary; in areas of the country with high humidity, this period can be as long as an hour. Lower humidity can reduce the off-cycle to as low as 15-20 minutes. The most common mistake is not allowing enough off time for the pen to dry.

You will also need to include a 24-hour timer to shut the system off at night. Humidity levels tend to rise as the outside temperature decreases, resulting in lower evaporative rates that limit the cooling effect.

Configure the system to wet no more than half the pen. Mounting the foggers 54 inches high along the outside pen walls, with the nozzles pointing down at a 45° angle, provides the correct area for wetting the pen. To get accurate coverage in the pen area, choose a nozzle that emits coarse droplets that will fall quickly to cover a specific area. One example of the proper nozzle is Hog Slat's part number 61025, emitting a medium-sized droplet of about 250 microns. The ASABE standard describes this as similar to a "heavy drizzle."

Effective evaporation only occurs when there is substantial air movement across the pigs. Tunnel ventilated buildings supply sufficient airflow at 300 to 400 feet per minute. For naturally ventilated buildings, it is necessary to add stir fans to provide air movement when there is no outdoor breeze. The effective thrust of a fan is 2X (in feet) of its diameter.

For example:

18" fan - 36'

20" fan - 40'

24" fan - 48'

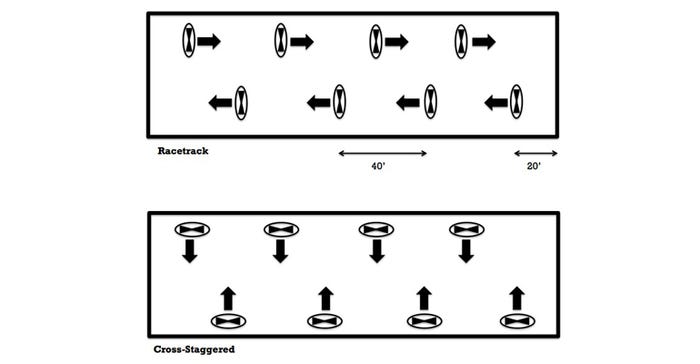

Choose from either racetrack or cross-staggered patterns to ensure proper air movement. Angle the fans in the racetrack pattern at about 20° towards the middle.

Sprinkler systems with sufficient air movement provide a cost-effective method to reduce summer heat stress for market pigs.

About the Author(s)

You May Also Like