Safety protocols regarding manure pits and manure handling should be developed by farm operations.

October 19, 2021

Entry into manure pits can pose a great danger to farm workers. Associated fatalities were occasionally reported. From 2010 through 2019, six people died in Ohio with their death related to manure pits or lagoons (DeMartini, 2021). These tragic incidents once again attest to the importance for pork producers to be aware of manure pit air hazards.

Characteristics and regulations

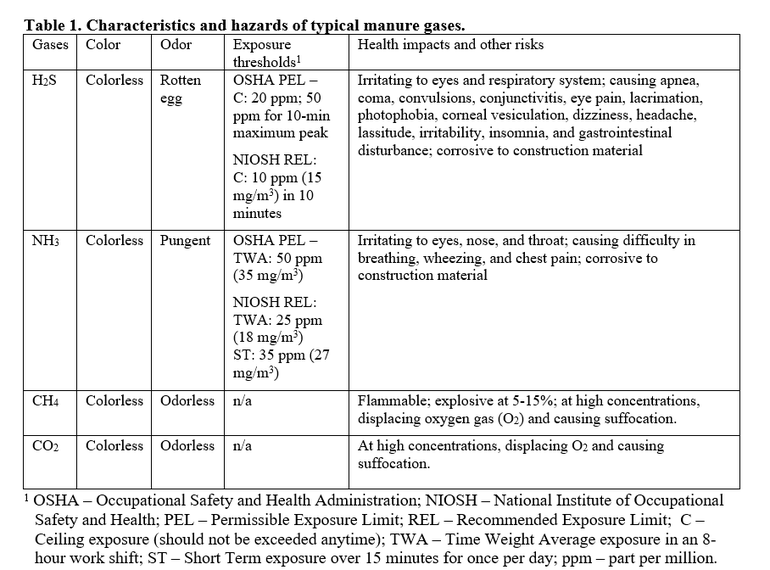

Four manure gases are usually of concern: hydrogen sulfide (H2S), ammonia (NH3), methane (CH4), and carbon dioxide (CO2). Among them, H2S, CH4, and CO2 are primarily produced from the anaerobic decomposition of manure, with little or no oxygen; whereas NH3 is produced from the mineralization of urine and feces. Their characteristics and risks are summarized in Table 1.

Specifically for H2S, the current OSHA regulation mandates a ceiling value of 20 ppm for an eight hour work shift. However, if no other measurable exposure takes place during the shift, a peak value of 50 ppm is permitted for a single-time exposure of no more than 10 minutes. The current OSHA regulation for H2S is based on data from the 1960s. More stringent regulations (TWA: 1 ppm; ST and C: 5 ppm) are being discussed by the American Conference for Governmental Industrial Hygienists (ACGIH) (OSHA, 2021). It is important to note that OSHA regulations do not apply to swine farms with less than ten employees. However, following the regulations is critical for ensuring a safe working environment for farm workers and good welfare for pigs.

The release of H2S, NH3, and CO2 from pit manure has been well characterized. For instance, in a deep pit wean-to-finish barn, H2S, NH3, and CO2 were found to release at an average flux of 6.2, 117, and 4,100 mg/m2-h (i.e., milligrams of gas released per m2 of pit area per hour), respectively, in summer (Ni et al., 2000). Manure gas risks are generally higher in summer because of the enhanced decomposition of manure at elevated pit temperatures. Other than gas release rates, factors such as gas density and ventilation also impact associated safety and health risks.

Among the four manure gases, NH3 and CH4 are lighter than air. Thus, they can disperse away fairly quickly when a pit access point becomes open. Comparatively, H2S and CO2 are heavier than air and tend to stay in the pit, thereby raising a greater risk. H2S tends to bond to pig manure and release in a large quantity when the manure is agitated. Thus, its risk is especially high during manure handling and pumping. A common misunderstanding about H2S is that since H2S carries a strong odor we can count on our noses to detect its presence. The gas does carry a characteristic smell, with a very low recognition threshold (0.0047 ppm). However, it can quickly dull a person’s sense of smell, even at low concentrations (NCIC, 2005). Therefore, to play safe, one should always assume that H2S cannot be seen or smelled, and respond accordingly.

Safety measures

Several articles have discussed relevant measures in detail, including Doss et al. (1993) and Roger (2018). In short, there are several general rules to follow:

Stay away from a pit unless it is necessary;

Turn on all fans during manure agitation and pumping;

Do not work in a pit alone – at least two people should stand by around the pit for support and possible rescue;

Use a self-contained breathing apparatus (SCBA) if pit gas conditions are uncertain, or call professionals with SCBA equipment;

Use gas meters to assess the condition of the pit gas, including O2 (which should be >19.5%), H2S (to ensure that it is lower than the OSHA PEL), and CH4 (to ensure that it is <5%);

Use approved harnesses and rescue robes for anyone entering a pit;

Call 911 when a critical situation occurs.

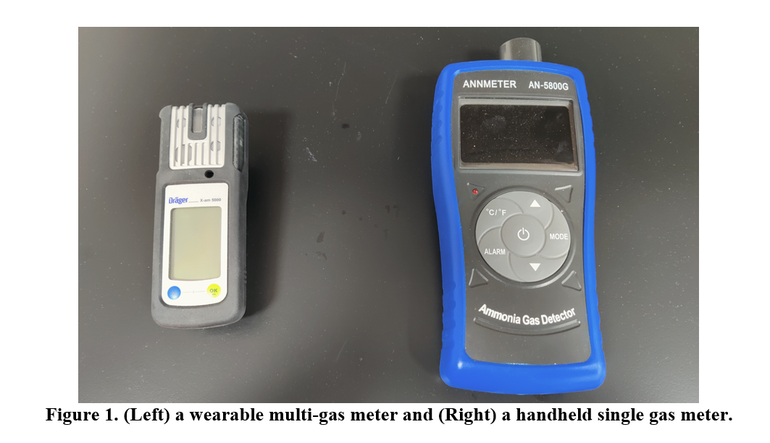

Regarding gas meters, advances in sensor technologies have made solid-state detectors more affordable than ever before. These solid-state detectors can be handheld or wearable and typically cost several hundred dollars per unit. Two example detectors are shown in Figure 1. In addition to solid-state detectors, gas detection tubes and badges are still widely used in the industry because of their affordability and ease to use. However, these tubes and badges are often for one-time use. Detailed information can be found from vendors such as Cole-Parmer.

Planning is always important. Safety protocols regarding manure pits and manure handling should be developed and delivered to all farm staff, including those who are not directly involved with manure handling duties. Warning parcels should be placed at all entrances to manure pits or storages where manure agitation is taking place. All these are tied to proper training. Through the training, every farm staff should recognize the risk posed by manure pit gases, understand the meaning of warning signs, learn the operation of safety equipment, and know how to respond when danger occurs.

References:

DeMartini (2021). Manure pit fatalities spur awareness. Ohio State University News Presses. Accessed at https://cfaes.osu.edu/news/articles/manure-pit-fatalities-spur-awareness

Doss, H. J., Person, H. L., & McLeod, W. (1993). Beware of manure pit hazards. Michigan State University Extension. Accessed at https://nasdonline.org/static_content/documents/1292/d001097.pdf

NCIC (2005). Safety Bulletin, October 2005. North Carolina Industrial Commission, Raleigh, NC. Accessed at http://www.ic.nc.gov/archives/1005safe.pdf

Ni, J. Q., Heber, A. J., Diehl, C. A., & Lim, T. T. (2000). Ammonia, hydrogen sulphide and carbon dioxide release from pig manure in under-floor deep pits. Journal of Agricultural Engineering Research, 77(1), 53-66.

OSHA (2021). Hydrogen sulfide standards. Occupational Safety and Health Administration, Washington DC. Accessed at https://www.osha.gov/hydrogen-sulfide/standards

Patnaik, P. (2003). Handbook of Inorganic Chemicals, McGraw-Hill Professional, New York City.

Rogers, E. (2018). The dangers of manure gas and strategies for mitigation. Michigan State University Farm Management. Accessed at https://www.canr.msu.edu/news/the-dangers-of-manure-gas-and-strategies-for-mitigation

You May Also Like