The computer vision system labeled sow posture with an accuracy greater than 99%, and greater than 95% accuracy for all behavior labels.

August 6, 2019

By Suzanne M. Leonard, Benjamin C. Smith and Brett C. Ramirez, Department of Agricultural and Biosystems Engineering, Iowa State University

Monitoring individual sow health and welfare can be challenging in a commercial production system. Labor considerations limit continuous human observations; thus, new technologies in precision livestock farming are working to fill this gap by monitoring individual animal behavior.

When potentially health challenged, animals will change their behavior, such as piglets decreasing activity or sows decreasing feed intake. These behavioral changes often occur days before differences are seen in the production outcomes or noticed in periodic observations by animal caretakers. However, technology can be integrated into production systems to identify changes in behavior that may be indicative of opportunities to improve animal health or comfort. Such systems can alert caretakers to the at-risk animal and lead to earlier interventions. There are many technologies available, but two developed recently at Iowa State University will be discussed here.

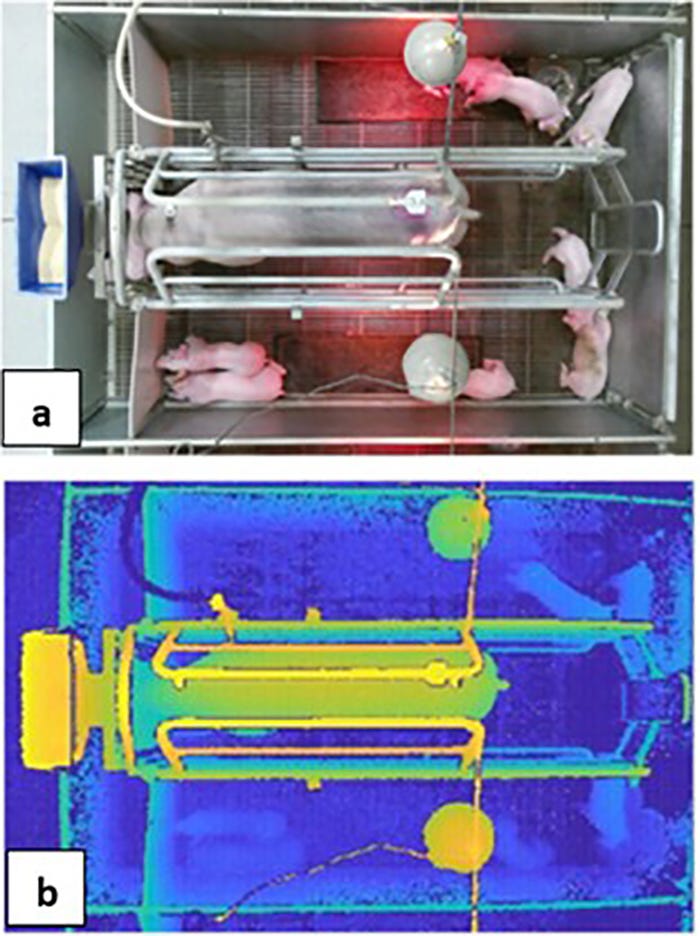

Developed primarily for a research setting, a computer vision system was created to monitor sows and piglets housed in farrowing stalls. Above each farrowing stall a Microsoft Kinect V2 was mounted to capture digital and depth images of the animals below. Images were taken once every five seconds for the entire duration of the five-week farrowing and lactation cycle. Specialized processing algorithms were developed to interpret the information captured in the images and identify the sow’s posture as sitting, standing, kneeling or lying. When labeled as lying the orientation of the udder was labeled. If occupying one of the other postures, the sow was labeled as eating, drinking or other behavior. Program labels were compared to the ground truth as determined by human observers to determine label accuracies. This system labeled sow posture with an accuracy greater than 99%, and greater than 95% accuracy for all behavior labels.

This system can be used to evaluate the effects of changing features of the farrowing environment on sow and piglet behavior. For example, with this system researchers can monitor the amount of time individual sows spend lying, orientation of the udder and if the sow is feeding and drinking. Sow behavior patterns can be compared among experimental treatments to determine if a particular treatment (crate layout, supplemental heat source type and placement, etc.) results in more desirable sow behaviors (e.g., less frequent postural changes). Coupled with production records, this information can be used to evaluate various farrowing stall designs for productivity and sow health to produce recommendations for farrowing stall designs.

An alternative approach is hardware-based to determine the sow’s posture. This method detects sow posture (standing, lying or other) by utilizing feedback from three depth sensors. These three sensors are installed above the sow on the farrowing crate and spaced equally along the length of the stall. While it cannot monitor a sow’s eating behavior, it does have the advantage of determining the sow’s posture in real-time for lower development and computational costs. Through the initial testing and development phases the system accuracy is averaging at 90% to a machine vison system for posture detection. Applying this type of system to a production system could offer producers the ability to detect the onset of farrowing and dangerous behaviors (high frequency of posture changes) during lactation.

Technology in the farrowing room will offer the possibility of improved productivity and efficiency through early identification of health and welfare concerns. By monitoring behavior, caretakers can intervene earlier as well as make better management decisions on an individual animal basis. As precision livestock farming technologies emerge, their limitations must also be considered, such as the uniqueness of every sow, farrowing stall, room, manager, etc. and the robustness needed to withstand the barn environment. Nevertheless, the trend will continue to focus on accurate technologies to aid producers in daily tasks to increase overall production efficiency.

References

Leonard, S.M., Xin, H., Brown-Brandl, T.M., & Ramirez, B.C. (2019). Development and application of an image acquisition system for characterizing sow behaviors in farrowing stalls. Computers and Electronics in Agriculture, 163(104866). https://doi.org/10.1016/j.compag.2019.104866

Smith, B.C., Ramirez, B.C., & Hoff, S.J. (2019). Infrared proximity measurement system development and validation for classifying sow posture. 2019 American Society of Agricultural and Biological Engineers Annual International Meeting. Paper No. 1900327, St. Joseph, Mo. https://doi.org/10.13031/aim.201900327

Sources: Suzanne M. Leonard, Benjamin C. Smith and Brett C. Ramirez, who are solely responsible for the information provided, and wholly own the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like