Geo-fabric fences help reduce odors and dust.

February 8, 2019

U.S. pork producers, and American farmers as a whole, have long been quick to adopt the latest technologies if they can improve production of livestock or crops. Some technologies won’t budge the needle on pigs per sow per year or average daily gain, yet pig farmers still implement innovations to improve the operation — maybe for the caregivers or the environment.

When technology touts odor reduction qualities, producers will stand up and take notice.

Iowa Select Farms, based in Iowa Falls, Iowa, is just one pork production company that has installed electrostatic precipitator fences after hearing about the odor reduction claims of the technology. Marketing claims are one thing, but can such technology stand up to the rigors of a U.S. hog facility in operation?

Substantiated claims

That is exactly what Daniel Andersen, associated professor of agriculture and biosystems engineering at Iowa State University, sought to find out. Starting in June, he conducted a four-month trial at two of ISF’s farms near Alden, Iowa, to see if the technology did indeed reduce the amount of odor and dust leaving the barns. Both sites consist of two tunnel-ventilated 101-by-190-foot barns, with fans on the north wall. Both facilities are equipped with an electrostatic fence consisting of two electrically charged lines of barbed wire powered with 30,000 volts that will “knock down” the odor-carrying dust particles exiting the fans of the tunnel-ventilated barn.

“In terms of performance we didn’t see a lot of variance between the two sites,” Andersen says. “We saw higher odor coming out of one barn; but as far as a percent reduction, which the system is doing, they are pretty similar.” Andersen says the reason that the one barn had higher odor emissions was because pigs entered that barn earlier and thus were at a different growth phase. “And that meant slightly different ventilation rates, and ventilation is going to control the odor concentration that we’re going to measure coming out.”

Measurements were conducted every other week for the four-month period. Tedlar bags are used to collect odor samples, as Andersen says odor compounds do not stick to the Tedlar material. The odors captured in the bags are diluted at the laboratory to achieve detection thresholds to be tested by the panel using the olfactometer. “The human nose does come into play, but the panel is put through a screening that they need to smell a standard within certain range to qualify,” Andersen says, noting that one’s sense of smell can be subjective. “Olfactometry is a scientifically validated method of collecting and testing odors.”

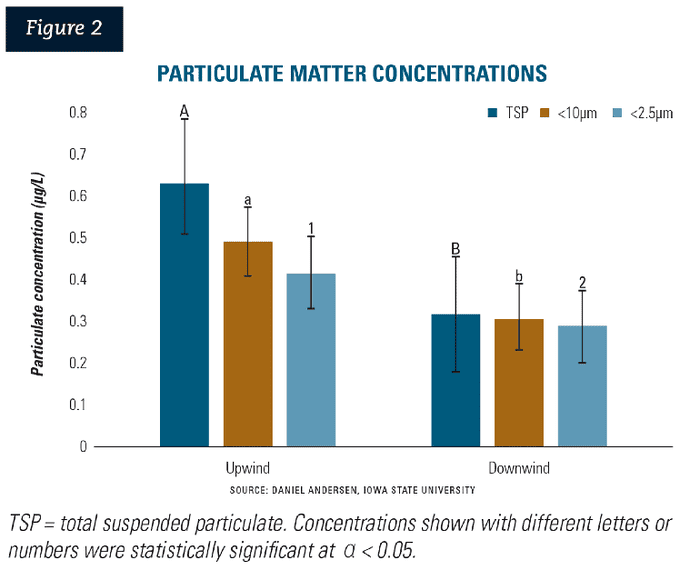

Odor attaches to dust particles, thus it is equally important to reduce the quantity of dust particles leaving a hog facility; and Andersen thought it important not only to check the amount of dust, but also the particulate size. “We like to look at 2.5 and 10 microns, because some people believe there are health indications. Your nasal passages do a good job of filtering out anything above 10. Anything below 2.5 will go through, but we’re concerned about what’s between that 2.5 and 10, because that can get stuck in your lungs” and cause health issues. Dust was captured before and after the electrostatic precipitator using an air sampler pump.

Downwind impact

Taken together, these parameters will provide ISF with the data required to understand the impact this system has on odor downwind of the facility. The olfactometry data can be used in the community assessment model developed by Steve Hoff, an agricultural and biosystems engineering professor at ISU. The CAM is used to determine “how often a neighbor so far away will receive odor from a certain building,” Andersen says. Though its use is not required when a producer is looking for a site to locate a new facility, Andersen says producers can use the CAM predict how often a neighbor may experience odor.

Andersen says his research sought to determine if the charged wires did indeed reduce both odor and dust coming out of the barn’s exhaust fans, as well as if odor and dust were further reduced after passing through the geo-fabric fence.

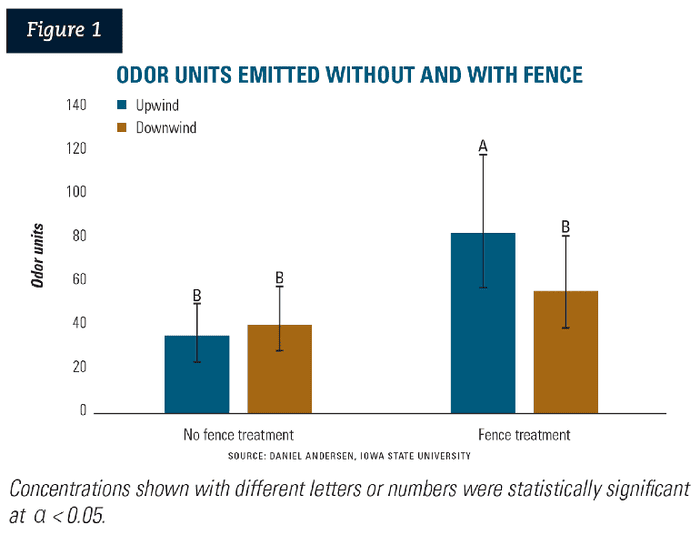

While Andersen says no statistical difference in odor concentration before and after the fabric fence was noted when the electrostatic fence was off, however, “We did see a statistical difference when the fence was on, with the average reduction in odor being 31%.” Overall, this shows that the electrostatic fence was causing an odor reduction, and it was due at least in part to the electrical discharge impact on odor. With the geo-fabric fence only, a statistical difference wasn’t seen in odor before and after the fence (Figure 1).

Of ‘particulate’ concern

As far as dust reduction, Andersen says a statistical difference in dust reduction was not detected when the fence was on or off, but dust between the fan outlet and the measurement point was statistically reduced in all cases. He says this isn’t dust removal directly due to the treatment system, as some of the dust would have settled anyway as it moved away from the fan, “but from several tests we ran without the geo-fabric fence present, it did serve to further reduce dust by about 20% to 30%.”

The electrostatic fence showed statistically significant reductions (p < 0.0001) for all three sizes of particulate matter (total suspended particulate, particulate matter less than 10 microns and particulate matter less than 2.5 microns). Reductions were 50% for TSP, 37% for particulate less than 10 microns and 31% for particulate less than 2.5 microns. The results are summarized in Figure 2.

Andersen’s research shows the electrostatic geo-fabric fence system performed well, reducing odors by 31% and dust of various sizes by 31% to 50%, levels similar to or slightly better than those previously reported in literature for an in-barn system. Original estimates of odor reduction were 12%, reported for an in-barn system.

Dust removal efficiencies were similar, with reductions of 39% to 65% being reported in literature, versus the 31% to 50% reductions found in this study. In this case, the difference may be primarily due to sampling location, as dust measurements in-barn tend to be higher than those emitted by barn fans, which make higher reductions likely.

In theory, the dust that exits through the exhaust fans, if not knocked down, will catch on the fabric fence. Over time, the dust particulates will need to be washed off to maximize catching capacity; or, as Andersen says, the timely rains throughout the study period were adequate to wash the dust from the fence and rejuvenate its capture potential.

As impressive as these results are, these electrostatic-geo-fabric fence systems are not for every producer, as the cost may be a prohibitive factor. Andersen points to nature as having a good odor-dust reduction system in a vegetative buffer in trees or shrubs. He says the ISU Air Management Practice Assessment Tool has indicated that producers may see an additional benefit of 5% to 15% reduction in odor by planting a vegetative buffer around the facility.

Vegetative buffers

ISF has made a point of adding vegetation buffers to new sites, and Andersen says he would like to revisit these sites for further testing to see if odors and dust are further reduced once the trees and shrubs reach maturity.

“Vegetation buffers have been shown to work pretty well, and they are something that most producers should think about,” Andersen says — not only for the odor and dust reduction qualities, but also for improving the site’s “curb appeal.”

Pit fans are common at hog facilities; but at these particular ISF grow-finish barns, the pit fans were turned off during the summer months, allowing the tunnel ventilation to handle the odor removal. “This has the potential to reduce odor from the facility by another 10% to 20%,” as typically, pit fans do, he says.

Lessons learned over time also help, as Andersen mentions a newer ISF construction where pit fans have been removed altogether, moving the pit fans up the sidewalls. “That sounds like a small change. But when you think of where odor comes from in a barn, the majority of it comes from the manure; so when we ventilate right at the pit level, we are pulling out the smelliest air and exhausting that,” he says. “By moving those pit fans up into the sidewalls, we’re pulling cleaner air that’s near the pigs.”

Andersen acknowledges that previous research shows fan location doesn’t drastically change the air quality within the barn, “so we might as well put them up and emit just a few less odors. … This research, not mine, shows an odor reduction of 10% to 20% just by moving fans around, so that’s not too bad.”

In addition to Andersen wanting to extend research once the vegetation buffers mature, he says he and John Stinn, ISF environmental projects manager, have discussed altering the design of the electrostatic fence for even better performance — possibly looking at the spacing of the charged wires.

Regardless, as producers adopt new technology, or adapt nature to do the dirty work, it is imperative for producers to do their part in keeping the environment clean and the neighbors happy.

You May Also Like