Innovative Insulation Inc. innovates again, applying its 34 years of expertise benefiting the agricultural industry to help farmers reduce energy costs.

January 10, 2020

Sponsored Content

The financial losses wrought by heat stress on producers and the pork industry costs U.S. pig farmers about $900 million in revenue according to an estimate by Steven Pollmann, PhD, a livestock consultant and former president of western operations for Murphy-Brown LLC, a division of Smithfield Foods.

These losses include impaired sow productivity as well as losses from grow-finish pigs. Pollmann estimates that on average producers lose $50 to $60 per animal each year due to heat stress.

Since pigs lack the ability to sweat, they are extremely sensitive to heat. They become susceptible to heat stress at about 70 degrees F (21 degrees C). If temperatures stay at 80 degrees F (27 degrees C) or higher for several days, it could have a myriad of negative effects on breeding herds, sows and those at the grow-finish stage of production. Under such high temperatures, pigs also experience reductions in performance.

"Heat stress is far and away the single biggest loss we see," Pollmann says. "It will have more impact on the industry than disease because it hits every farm. Heat stress, particularly in the North American market, will hit 95% of the herds."

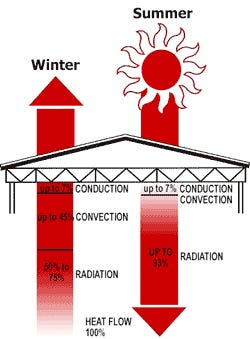

Perry Faulk Sr., executive director at Innovative Insulation Inc., gives a practical explanation of the heat stress problem, and a practical solution to eliminating heat stress issues in hog barns. "One challenge for hog farmers to reduce heat stress economically starts with the architecture of the modern hog house. The modern hog house is a pole barn wrapped in sheet metal. Sheet metal is well known as a superior conductor of radiant heat from the sun. The sheet metal's daytime temperatures during a typical sunny day can exceed 150 degrees.

"Traditional insulation like fiberglass or foam insulation are conductive insulations and are not well suited to combat high temperatures due to radiation. The attic temps under the metal roofs and above the insulated drop ceilings of a hog house can exceed 150 degrees as well. By the middle of the day, the high temperatures in the attic space defeats the insulation above the drop ceiling.

"If you can eliminate the radiant heat that enters the attic space, you can effectively cool the hog house by 60 degrees in the summer. We have installed millions of square feet of Ag Barrier, an agricultural radiant barrier that blocks 96% of radiant heat with the assistance of our partners like Bridgeport Corp. with tremendous results. We have effectively removed up to 60 degrees from these buildings in the summer, reduced propane expenses in the winter and eliminated condensation from under the metal roofs as well."

Jason Whitmore, an agricultural specialist for Bridgeport Corp. in Sioux City, Iowa, with more than 30 years' experience providing equipment into the hog industry explains, "This is Bridgeport's third year working with Innovative Insulation. We started off using their bubble product. Then the last two years we have seen the value of their Ag Barrier. To date, we have three million square feet installed.

"We are finding Ag Barrier is outperforming the other types of insulation. It is so much easier to install, half the cost, and provides much more radiant barrier. Everyone that has used the Ag Barrier loves the results they are seeing. We are getting readings of 40- to 60-degree cooler attic temps in the summer months.

"We are finding Ag Barrier is outperforming the other types of insulation. It is so much easier to install, half the cost, and provides much more radiant barrier. Everyone that has used the Ag Barrier loves the results they are seeing. We are getting readings of 40- to 60-degree cooler attic temps in the summer months.

"In the Midwest, like most, everyone uses a poly barrier to line their ceilings. We have found that using Ag Barrier does not trap moisture in the ceiling or your roofs, saving you a lot of LP (liquefied petroleum). This being said, Bridgeport is a proud supporter of Ag Barrier and what it brings to the ag industry, including its lifetime warranty which no other insulation carries a lifetime warranty."

Ag Barrier is useful in battling harmful radiant heat in multiple agricultural/livestock buildings such as:

Hog farms

Poultry houses

Stables

Dairy/milking facilities

Ag Barrier offers a wide range of applications and products for installation in agricultural and livestock buildings. Depending on the structure of your building and the level of benefit required, there is an energy efficient "easy-to-install" option to consider.

Wide range of performance options (R-value depends on application)

Quicker installation results in lower labor costs

Product does not contain fibers or dust that require respirators or protective garments

Lowers stress levels in livestock due to lower internal building temperatures (radiant barrier application blocks 96% of radiant heat)

Reduces the impact of the "black-globe effect" on livestock (reduces the absorption of radiant energy by the animal's body and results in higher weight gain and reproductivity and lower mortality rates).

Non-toxic and non-carcinogenic.

Ag Barrier's retail cost of 13.9 cents a square foot makes Ag Barrier the most economical option for animal confinement insulation.

Ag Barrier is a simpler economical solution to the toll heat stress takes on pigs. It improves performance, reduces chronic disease, improves feed intake and lowers mortality rates. For more information contact:

Perry Faulk Sr.

Executive Director

Agricultural Specialist

Innovative Insulation Inc.

1-800-825-0123

About the Author(s)

You May Also Like