Schedule a preseason tune-up for your fans to maximize their performance this summer.

March 3, 2020

Sponsored Content

When it comes to cooling pigs, wind speed is critical. And when it comes to moving the large volumes of air in tunnel-ventilated buildings, we rely on large energy-efficient fans. Follow this checklist before hot weather comes next summer.

1) Replace rubber fan belts annually. Fan belts don't stretch. Instead, they wear from constant contact against the pulleys. As they get thinner, they ride lower in the pulley grooves, causing the fan blades to rotate slower. Since the fan's air output is directly related to blade speed, it's not uncommon to see fan delivery diminished by as much as 20% because of worn belts. See this simple guide for measuring the correct belt replacements.

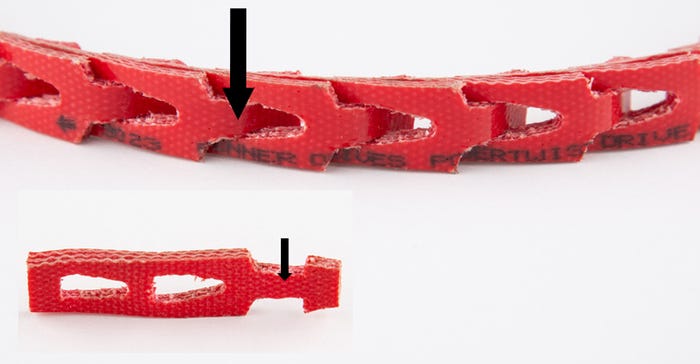

If your fans use a link-style belt, check for cracks on the neck portion of the individual links. The neck is the part of the link subject to the highest amount of stress as it rotates around the pulleys. Replace the entire belt, not just the damaged link. Since every link is subject to the same amount of flexing, the rest of the links will probably continue to fail in short order. Click LINK BELT for instructions on installing a link-style belt and watch the videos at the bottom of the page.

2) Check the pulleys. While you have the belts off, visually examine the pulley grooves for wear. The grooves should have a sharp V shape. Replace pulleys with rounded grooves. An excellent tool for aligning new pulleys with the existing drive assembly is the Laser Fan Pulley Alignment Kit. Easy to use, just place the laser pointer in the pulley groove and adjust the target piece in the new pulley until it lines up. The target piece also functions as a pulley groove gauge to check existing pulleys for wear.

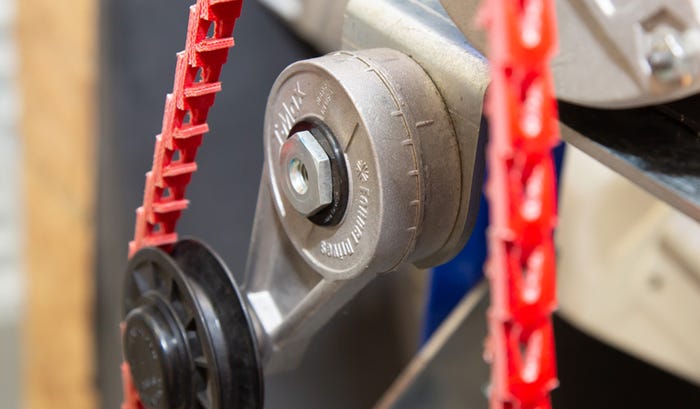

3) Check the automatic belt tensioner. This device contains internal springs that push against the belt to maintain its tightness. Work it several times to ensure the tensioner is not seized.

Also check for proper tension. With the belt on, the indicator bar should register between the first and second marks on the tensioner body. To increase the amount of tension, use a 15/16 wrench to rotate the body nut counterclockwise.

4) Check bearings for "wiggle." Bearings should be firm on the shaft to prevent vibrations that cause excessive wear in the entire linkage system.

5) Clean interior shutters. Dirty fan shutters can reduce fan output by 8%. Clean shutter vanes with a soft bristle brush or broom and keep the brush on the wall by the fans where it is handy to keep the shutters clean throughout the season. Replace any damaged vanes or vane rods that prevent them from opening and closing smoothly.

6) Replace any cone or cone sections that have been damaged by snow, ice or strong winds. Cones add 10% to fan performance, and missing parts decrease their effectiveness.

Performing preseason maintenance on summer fans will ensure they are operating to their full capacity during hot weather ahead.

About the Author(s)

You May Also Like