Research confirms intact males grow more efficiently and produce leaner carcasses than those that were physically castrated.

One by one, food companies and retailers are announcing responsible sourcing standards for their suppliers. For the swine industry, eliminating gestation crates usually leads the list on animal welfare policies. Still hovering in the shadows, physical castration may just be the next big welfare issue. Since physical castration involves cutting and manipulating innervated tissues, the pig’s pain is the focus of the animal welfare discussion.

Castration, a longtime proven practice, is performed to avoid boar taint in the meat of sexually mature males and reduce the aggression toward other pigs and people. However, many countries are requiring alternative standard operation practices in order to reduce the pig’s pain during physical castration. It is mandatory to use local or general anesthetic in Norway, Switzerland and the Netherlands. Nearly all of the males are intact when marketed in the United Kingdom and Ireland.

As researcher John McGlone of Texas Tech University verified in 1988, pain is associated with surgical castration. Alternatives to physical castration exist. As stated by the Texas Tech University team, hog producers can market male pigs before puberty, use pain relief, select genetics against boar taint or utilize immunological castration. Each option has its advantages and disadvantages in terms of feasibility and impact on the hog operation’s profits.

Applying anesthesia can be the easiest to adapt to, but not without impediments. Despite the fact local anesthesia can relieve procedural pain, it can wear off in about 30 to 60 minutes. Similar general anesthetics are effective, but they can cause complications for young pigs. Putting these issues aside, the use of anesthetics in food animals in the United States is yet to be approved by the Food and Drug Administration or USDA.

For hog producers looking for different alternatives to physical castration, immunological castration (IC) may be the place to turn. In simple terms, IC is a protein compound that protects against off odor, but it is not a hormone or growth promotant. The generic name for the active ingredient is gonadotropin releasing factor analog-diphtheria toxoid conjugate. Its mode of action is to temporarily and immunologically block gonadotropin releasing factor, which reduces the levels of androstenone and skatole in mature male pigs — the primary source of “off odors” in pork. Utilizing the pig’s own immune system, it creates the same effect as physical castration by managing the substance responsible for unpleasant aromas in pork from male animals.

Currently, IC has government approval in over 60 countries including the European Union, Australia, Japan and the United States under the brand names Improvac and Improvest. Some global pig farmers have actually used these products successfully for more than 10 years. Yet, the United States is slower to adopt the IC approach.

Real-world testing

Switching up production practices should not be an overnight decision. It calls for weighing the impact on animals and workers along with the farm’s profitability. Past research has well documented that intact males grow more efficiently and produce leaner carcasses than those that were physically castrated.

For several years, integrators have been experimenting in feeding intact males on company farms, with feed efficiency being the main reason. In various regions, contract growers are finishing out intact males in commercial operations this year on a limited basis. The pork is marketed and processed through the normal production channels because the USDA-certified process classifies animals as barrows, and therefore, does not warrant testing for off odors during inspection.

Research confirms the greater average daily gain and greater feed conversion. In fact, tweaking the feed rations can enhance the feed efficiency, according to researchers from Iowa State University and the University of Illinois.

“This research suggests we can improve average daily gain and feed efficiency by as much as 10% by increasing lysine levels at critical times of production,” says Daniel Nelson, Ph.D., PAS, senior nutritionist, Pork Technical Services with Zoetis.

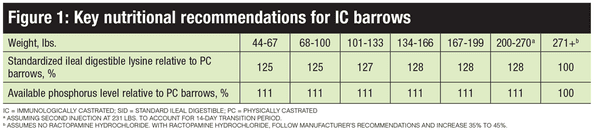

According to the research, higher lysine levels trigger greater response in ADG and feed efficiency of intact males (Refer to Figure 1 for key recommendations on feeding IC barrows).

■ Dietary requirements for lysine and phosphorus are higher for IC barrows than for physically castrated barrows until two weeks after the second dose, which is administered around 13 weeks. Because the average daily feed intake of IC barrows increases dramatically at this time, nutrient fortification can be reduced to the levels provided in a production system’s existing PC barrow diet.

■ Specifically, dietary concentrations of lysine and phosphorus should be increased to optimize ADG and feed efficiency.

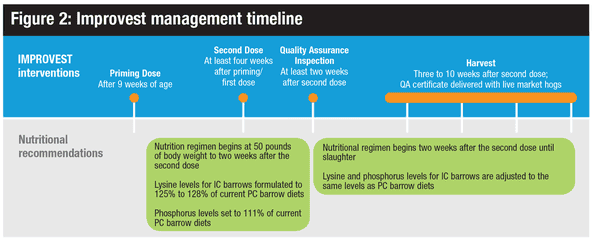

■ Lysine levels for IC barrows should be formulated to provide 125% to 128% of a production system’s current PC barrow diets, starting at approximately 50 pounds body weight through two weeks after the second dose of Improvest. Phosphorus levels should provide 111% of a production system’s current PC barrow diets for the same time period.

■ Beginning two weeks after the second dose of Improvest and until slaughter, IC barrows should be fed the same diets used for PC barrows.

On a farm near Greensburg, Ind., IC barrows are put to the test in a real-world setting. The nursery-to-finish facility houses 500 male pigs in groups of 25, all raised under the same housing and management standards found in a typical commercial swine operation setting with high school-aged caretakers managing the day-to-day operations of the farm under the supervision of farm owner Larry Rueff, DVM. The intact males are received from local producers and are not handpicked. Instead of being castrated, male pigs at the demonstration farm receive two doses of the FDA-approved veterinary prescription product to grow as intact males. The administration process is overseen by a certified Zoetis staff member; the FFA students do not administer Improvest.

Bill Beckman, Zoetis, administers the second dose of Improvest as high-school-aged workers assist while observing the procedure.

Rueff and Bill Beckman, Zoetis area application manager, host groups from retailors to packers to producers. The research farm site is also used as a place to train individuals. “The demonstration farm is a place to show Improvest in action. I am a big believer when you get people in the barn, they can see it, and their responses are more real,” says Rueff.

The ninth group of pigs was present on the farm recently when Beckman demonstrated administrating the second dose of the product while Rueff reviewed the nutritional program formulated by Zoetis. Reviewing the performance data, the feed efficiency was 2.35 on the first five groups fed wean-to-finish meal diets.

After tweaking the same meal diets to reflect the new recommendations, the feed efficiency for the IC barrows of group 6 and 7 was 2.14 and 2.15, respectively. As for the average daily gain, the IC barrows on meal diets average 1.9 pounds per day while group 6 and 7 penciled in at 2.18 pounds per day and 2.05 pounds per day, respectively.

Reviewing the basics

Still, it is clear there is hesitation to adopt the technology in the United States. Rueff says it is a change. Historically, vaccinations are given at weaning age. Any time you ask a producer to administer a vaccination at 10 weeks of age or older, there is going to be a pushback. It is reasonable for a hog farmer to question the practical nature of the program. Therefore, rigid protocols are established to protect the administrator and ensure the quality assurance procedures are followed for marketed IC barrows.

Since it is a prescribed product and a certified quality assurance process, there are requirements for who can administer the product. The person must be trained and certified. The veterinarian must write a prescription. The information is loaded into an electronic platform on GlobalVetLink so any pig in the program is tracked and monitored. Every action is time dated and stamped, including the person administering the product. That all generates a letter of declaration that goes with the pigs when they are loaded on the trailer and is given to the processing plant upon delivery. This on-farm implementation program is approved by the USDA Food Safety and Inspection Service, verifying the process, and generates the certificate identifying the males as barrows for the packer.

Each intact male receives an injection behind the ear.

Each intact male receives two doses behind the ear. The first, or priming dose, is given at 9 weeks of age, followed by a second dose at least four weeks later. “The first dose has no effect on the pigs’ growth. The pigs are growing at their natural ability. Seven to 10 days after the second dose the behavior will change, and the pigs will transform into a barrow,” explains Beckman.

Within two weeks after the second dose, a quality assurance inspection is conducted. The group is monitored for a period of time for riding activity, vocalization and any other aggressive behavior. However, Beckman points out that the observer must know the difference between a learned activity, such as mounting, and actual thrusting. Any male exhibiting boar-like behavior is identified and given another dose.

Improvest has a zero withdrawal period; however, IC barrows cannot be marketed until three weeks after the second dose. The reason is it takes that long to remove the boar taint.

Because of concerned hog farmers, a special applicator was designed to prevent accidental self-injection, along with an extensive training and certification program for those responsible for giving the product.

“This device we use to inject pigs with is very safe. Once you insert a needle and take the sheath off, the needle is completely encased. It will not move. That is the safety aspect that eliminates that fear,” says Beckman as he demonstrates. “You squeeze the trigger and that unlocks the needle, allowing the product to be given safely.”

Bill Beckman, Zoetis area application manager, demonstrates the safety of the application device.

Furthermore, he explains, the training program is not just watching online videos and quizzes for more than five hours. It is in the barn, hands-on training with intact males.

As seen in a live demonstration, the entire process of actually giving the doses is smooth and quick. In fact, the animals calm down several minutes after the administration process (as seen in the photo below).

Realistically, all procedures have trade-offs. The method of castration is a choice of the producer. However, abandoning physical castration means more time for Day 1 pig care and the removal of scalpels from the barn.

“Any time you can take sharp objects out of the barn, it’s a good thing for workers,” says Rueff. “Unfortunately, workers can cut themselves when performing physical castration.”

Overall, Rueff says the program requires wean-to-finish sites to be better managers. “I actually believe that Improvest is an example of technology that helps us to learn to manage our finishing sites better. It forces us to perform certain tasks at certain times. We have to be aware of diets. I think it is a positive, and makes us manage finishing pigs more intensively.”

About the Author(s)

You May Also Like