Perhaps evaporative cooling pads may have greater effectiveness in finishing barns located in more arid climates outside of the Southeastern U.S.

May 10, 2018

By Jeff Wiegert, Sanjay Shah and Mark Knauer, North Carolina State University

Pork producers understand summer heat stress impacts finishing pig growth rate, yet significant reductions in summer market weights continue to be observed. A logical starting point to improve summer throughput is to identify cost-effective management strategies that improve barn environment.

Evaporative cool cell pads are large pads mounted on barns that cool the air entering the facility. This technology is commonly used in the broiler industry and on sow farms in North Carolina. Yet their potential for use in grow-finish facilities to alleviate seasonality in pig performance has yet to be characterized.

In the present study, barn environment, pig temperature and pig performance were measured in tunnel-ventilated finishing barns equipped with (Cool; n=two barns) or without (Control; n=two barns) evaporative cool cell pads. Both Cool barns (Figure 1) were created in 2013 by retrofitting tunnel-ventilated barns with cool cell pads (approximately 4-foot height x 30-foot length). Each barn used in the study had identical dimensions (approximately 40-foot width x 150-foot length), number of fans and were located on the same site in eastern North Carolina.

Figure 1: Tunnel-ventilated barns used in the experiment (bottom barn retrofitted with cool cells).

During the summers of 2014 through 2017, barn temperature and relative humidity were recorded every 15 minutes using data loggers at 20, 75 and 130 feet from the barn entrance. From each time point, a temperature-humidity index was calculated. Environmental data points were classified into daytime (9 a.m. to 9 p.m.) and nighttime (9 p.m. to 9 a.m.). Ambient climate conditions (Ambient) were obtained from a North Carolina State Climate Office (Raleigh, N.C.) weather station located four miles from the farm.

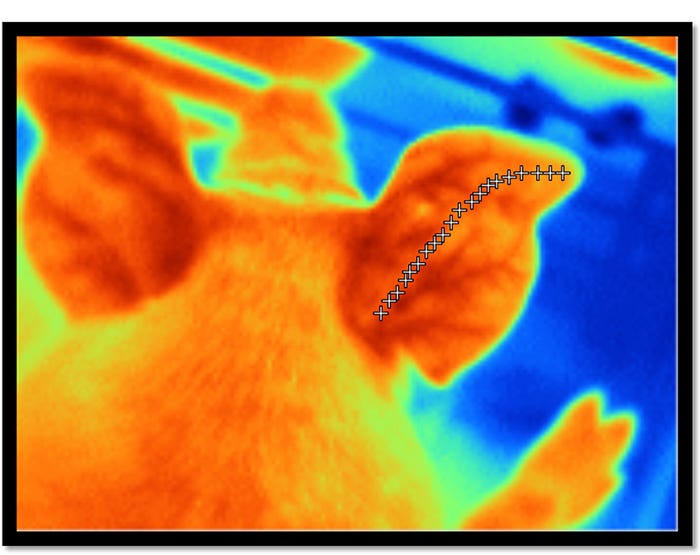

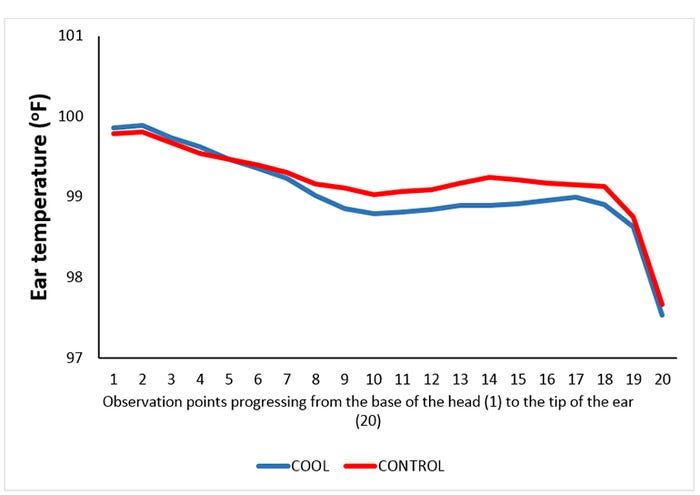

During summer 2016, pig heat stress was assessed using thermal imagery (Figure 2; Brown-Brandl et al., 2015). Thermal images are a noninvasive means of assessing an animal’s physiological state and present an accurate, practical and suitable alternative to measuring respiration rate and rectal temperatures in group-housed pigs (Brown-Brandl et al., 2013). Briefly, a thermal image of the back of the pig’s ear was recorded and the temperature gradient is measured along the midline of the ear from the warmest part of the ear (nearest the head) to the coolest part of the ear (nearest the tip of the ear). Because pigs utilize radiant heat transfer from the ears to dissipate excess body heat, a small ear temperature gradient (meaning that the tip of the ear is nearly as warm as the base of the head) reflects a considerable body heat load, while a larger temperature gradient indicates a more manageable body heat load. Therefore, pigs with smaller ear temperature gradients may be said to be experiencing a greater severity of heat stress than pigs with a larger ear temperature gradient. Pig average daily gain and feed efficiency were recorded during the summers of 2014 through 2017 and provided by the cooperating farm. Barn was considered the experimental unit.

Figure 2: A thermal image of the back of a pig’s ear. The ear temperature gradient is measured along the midline of the ear as indicated. Because pigs utilize radiant heat transfer from the ears to dissipate excess body heat, a small ear temperature gradient reflects a considerable body heat load, while a larger temperature gradient indicates a more manageable body heat load.

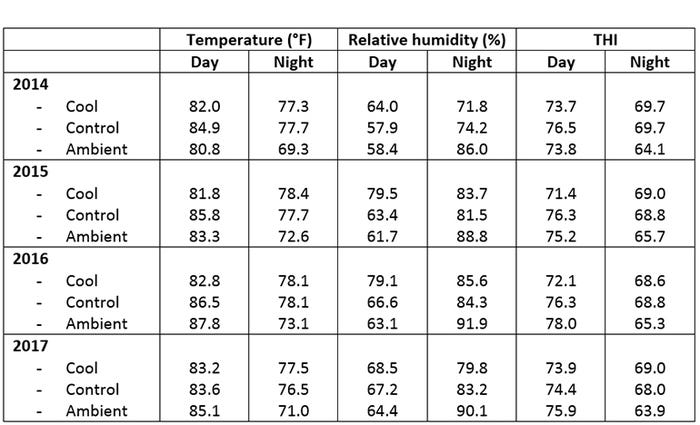

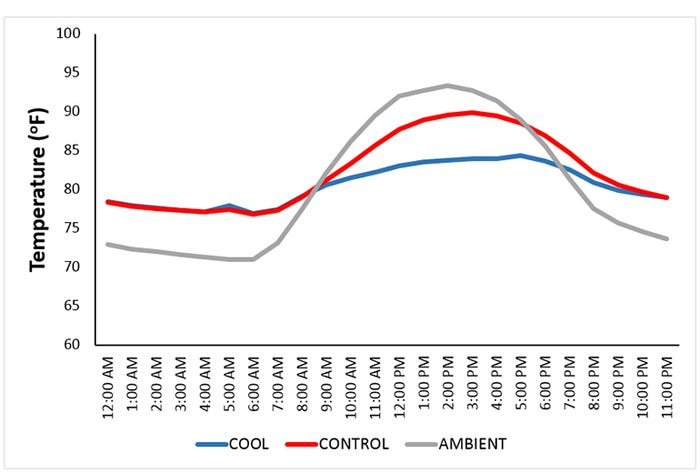

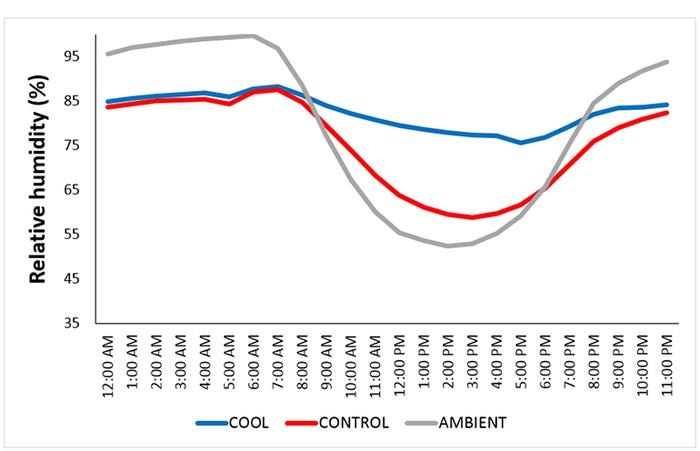

Average Cool, Control and Ambient environment during day and night are presented in Table 1. In general, the presence of evaporative cool cell pads decreased barn temperature and increase relative humidity during daytime, yet at night there are only minor environmental differences between Cool and Control (Figures 3 and 4).

Table 1: Average Cool, Control and Ambient environment during day and night during the summers of 2014 through 2017.

Figure 3: Cool, Control and Ambient temperature recorded in summer 2016 averaged over a 24-hour period.

Figure 4: Cool, Control and Ambient relative humidity recorded in summer 2016 averaged over a 24-hour period.

Similarly, temperature-humidity index was improved in Cool compared to Control during the day, but was largely similar between barns at night. Thermal image analysis similarly showed small differences in pig ear temperature (Figure 5), likely indicating that pigs housed in Cool and Control barns experienced a similar degree of heat stress. No differences were observed between Cool and Control for ADG (1.80 versus 1.80±0.02 pounds per day, respectively) or F:G (2.60 versus 2.53±0.06, respectively) during the summer months.

Figure 5: Ear temperature of growing pigs housed in Cool and Control in summer 2016.

Perhaps the increased relative humidity observed in Cool barns offset any potential benefits to be gained from decreased barn temperature. Researchers have previously reported that elevated humidity during hot temperature periods diminish the growing pig’s potential for heat dissipation via panting (Huynh et al., 2007). A more complete understanding of the interaction of temperature and humidity on pig thermal comfort in modern genetic lines may be required.

In summary, evaporative cooling pads decreased daytime barn temperature, but increased daytime relative humidity, did not impact nighttime barn environment and failed to improve pig thermal load or growth performance. Perhaps evaporative cooling pads may have greater effectiveness in finishing barns located in more arid climates outside of the Southeastern U.S.

Acknowledgements

The authors acknowledge support from the National Pork Board (NPB #13-101), the North Carolina Ag Foundation and Hog Slat Inc. (Newton Grove, N.C.) for donating the cool cell pads used in the study.

References

Brown-Brandl, T.M., R.A. Eigenberg, and J.L. Purswell. 2013. Using thermal imaging as a method of investigating thermal thresholds in finishing pigs. Biosys Eng. 114: 327-333.

Brown-Brandl, T.M., M.D. Hayes, G.R. Rohrer, and R.A. Eigenberg. 2015. Thermal comfort evaluation of three genetic lines of modern pigs using thermal images. In: Proc. 7th European Conference on Precision Livestock Farming, Milan, Italy. p. 700-710.

Huynh, T.T.T., A.J.A. Aarnink, M.J.W. Heetkamp, M.W.A. Verstegen, and B. Kemp. 2007. Evaporative heat loss from group-housed growing pigs at high ambient temperature. J Therm Biol. 32:293-299.

You May Also Like