Finishing facilities constructed with solid sidewalls lower operating costs and improve ventilation.

December 31, 2017

Sponsored Content

Evolution

For the last 20-plus years, the industry standard for finishing houses has been some variation of a total slat, double-curtain building design. This style of construction utilized lower cost curtain construction on the sidewalls.

As the design migrated north, some of the earliest adaptions to the buildings consisted of adding insulation to the sidewalls. Producers and builders used insulated or heavier weight curtains, removable bubble foil insulation and even eliminated the north curtain altogether, replacing it with a solid insulated wall.

A growing trend in new construction has seen a move away from curtain-sided finishing buildings. Several key factors have driven this movement to totally enclosed structures for finishing hogs.

Heat savings

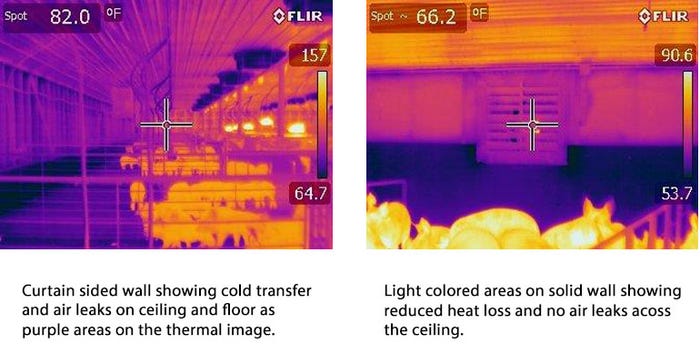

Replacing the sidewall curtains with high R-value insulated, solid wall can significantly reduce the amount of heat needed when starting pigs. A simple heat loss comparison of a 200-foot exterior wall pointed to savings of up to 0.25 gal of propane per hour. This building loss calculation also did not take into account the amount of heat needed to counter cold air leaks through tears or holes in the curtain or infiltration around the edges.

Improved minimum ventilation

The winter fans create a negative pressure inside the building drawing air from outside. Since even the best installed and maintained curtains are not airtight, cold outside air leaks in from around the curtains instead of entering through the ceiling inlets. Solid sidewalls eliminate curtain air leaks, so all the air comes through the ceiling inlets at a higher velocity. This cold, high-velocity air mixes with warmer room air near the ceiling before it swirls to pig level.

Reduced maintenance

With no curtains, hardware or curtain machines to repair or replace, producers can eliminate the annual fall maintenance program saving time and money during the busy harvest season.

Improvements in fail-safe protection

Sidewall curtains provide fail-safe protection against power outages. A simple curtain drop device connected to the winch handle allows the curtains to drop down to prevent suffocation. In practice, this system many times does not function as intended because of poor repair and maintenance. Advanced alarm system technology linked to environmental controls alert barn operators almost immediately of power outages or drastic room temperature changes.

Several producers, after seeing the benefits, have remodeled existing curtain-sided buildings into solid sidewalls. The conversion is relatively straightforward with extra 2x6 studs added to the sidewall framing, exterior steel siding, 6-inch batt insulation and interior wall covering of plywood, Fiber Reinforced Plastic, poly board or metal siding. For interior panels in animal contact areas, do not allow the panel edge to extend over the concrete wall and cover all panel joints with aluminum batten strips.

About the Author(s)

You May Also Like