Your minimum ventilation rate may be wrong

A minimum ventilation rate of 1.5 - 2 cfm/weaned pig is a well-accepted guideline

December 16, 2016

Sponsored Content

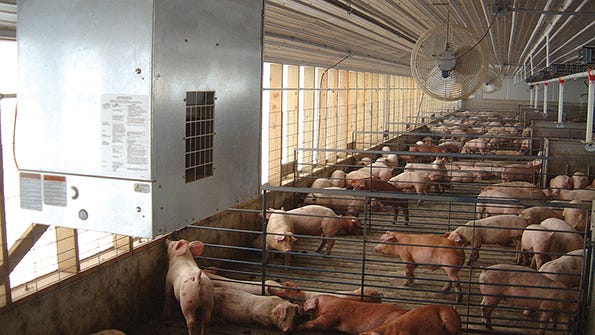

A minimum ventilation rate of 1.5 - 2 cfm/weaned pig is a well-accepted guideline. What is typically not taken into account is the additional ventilation required to remove combustion by-products from unvented heaters. In some cases, it is necessary to INCREASE the winter ventilation rate to 3 - 4-cfm/ pig to prevent excessive carbon dioxide (CO2) from being released into the animal environment.

Looking at a standard 1100 head, wean/finish building commonly built in the Midwest with (2) 250,000 BTU unvented furnaces

The minimum ventilation rates for the pigs

1100 pigs x 2 cfm = 2200 cfm

The owner’s manual for a popular brand of unvented heater lists the ventilation air required to ventilate the combustion of their 250,000 model as 1050 cfm.

2) 250,000 BTU heaters x 1050 cfm = 2100 cfm

While the minimum ventilation rate for the pigs exceeds that of the heaters, the increased CO2 levels may require an increase in ventilation, older less well-maintained heaters are more likely to require an increase.

Facilities equipped to use infrared gas heaters may require even higher ventilation rates.

The same 1100 head, wean/ finish unit uses (20) 17,000 brooders. Again from the manufacturer’s owner manual a rate of 200 cfm per brooder is suggested for air quality.

20) 17,000 BTU Brooder x 200 cfm = 4000 cfm

The natural tendency for barn operators is to reduce ventilation rates below minimum during cold weather to save on heating costs at a cost of pig and worker health. The additional carbon dioxide released from the gas appliances combined with increased humidity, dust levels and gas levels create a poor environment for growing pigs and barn workers.

Studies1 show that non-vented forced air heaters will exceed and sometimes double the 1540 ppm of CO2 during standard winter operation. This contributes to decreased lung function in animals and the increased susceptibility of disease2.

Ultimately a properly maintained and managed ventilation system will provide the optimum environment for healthy animals as long as the operator knows what factors to take into consideration.

1.Yang, Anthony Yuan-Jung. "Effect of heater type on CO/CO2 concentrations in a farrowing barn." MS (Master of Science) thesis, University of Iowa, 2015. http://ir.uiowa.edu/etd/1939.

2.Donham, K., Haglind, P., Peterson, Y., Rylander, R., & Belin, L. (1989). Environmental and Health Studies of Farm Workers in Swedish Swine Confinement Buildings. British Journal of Industrial Medicine, 31-37.

About the Author(s)

You May Also Like