Maintaining the ability to strategically use antimicrobials and more complex nursery diets to support the health and wellness of pigs should not be taken lightly

Maintaining the ability to strategically use antimicrobials and more complex nursery diets to support the health and wellness of pigs should not be taken lightly, according to Rodger Main, DVM, Department of Veterinary Diagnostic and Production Animal Medicine at the College of Veterinary Medicine at Iowa State University.

Main shared results and observations from an experience implementing a production model aimed at providing consumers with an alternative pork product raised without antibiotics. A 15-month working evaluation was conducted to understand the practical implications of executing an antibiotic-free (ABF) program in a large-scale production system.

Two of seven pig flows from a pyramid of isolated sow units were selected to enter into the ABF production scheme. The five flows not selected remained on conventional production feeding and management methods.

The objective was to produce a consistent flow of process-verified pigs that had never been administered antibiotics and were fed vegetarian diets, Main explained at the Iowa State Swine Disease Conference for Swine Practitioners last fall in Ames.

Overall, the farm health status and production environments were “very comparable” to other mainstream, upper Midwest, three-site production systems, he says.

For the ABF program, weaning age was increased from 18 to 23 days. Individually treated pigs were tagged, recorded and segregated from the rest of the group. ABF pigs received increased floor space in the nursery. Pigs on vegetarian diets were fed no plasma, lactose, fish meal, blood meal, milk products or animal fat, but instead received processed soy protein, dextrose and vegetable oils.

Additional growing pig vaccines used in the ABF pigs included oral K88 E. coli, salmonella, ileitis and erysipelas vaccines, along with a combination Mycoplasmal pneumonia-Haemphilus parasuis that replaced the Mycoplasmal pneumonia vaccine being used in the conventional pig flows.

ABF pigs were finished in more isolated grow-finish sites to minimize regional pig-density-associated disease pressures.

ABF vs. Conventional

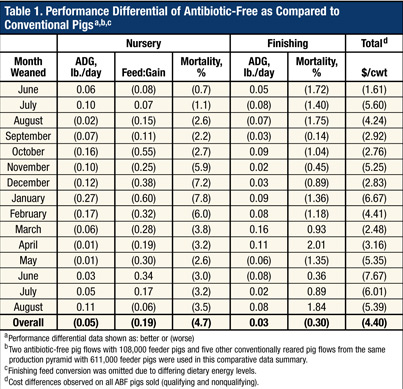

Comparisons of ABF vs. conventional pig flows were based on averages of monthly closeouts from June 2006 to August 2007 (Table 1).

Overall, ABF nursery performance lagged conventional output, with average daily gain in the nursery 0.05 lb./day worse and nursery mortality consistently 5% worse.

In finishing, there was no measurable impact on performance in terms of growth rate and mortality when the two production groups were compared.

“The impact on total cost of production from birth to market showed that it cost more to raise ABF pigs to the tune of about $4.40/cwt. or about $11/pig,” Main says.

However, the percentage of pigs actually sold as ABF-qualifying top hogs needs to be understood to more fully recognize the total opportunity costs they carry to slaughter.

For example, if only 70% of the pigs sold from ABF pig flows actually qualify, the cost difference between conventional and ABF is $4.40 vs. $6.29/cwt., he points out.

ABF dropouts are caused by individual pig treatments, cull pigs, group or whole-herd antimicrobial treatment, incomplete production records, or processors not buying ABF pigs caused by an imbalance of supply and demand.

Impact on Caretakers

Treating and managing animals to preserve animal health and well-being are at the core of animal caretakers’ training and sense of responsibility. ABF production programs add another level of complexity for those responsible for managing the pigs. “Treat and disqualify” or “wait and see” is a daily decision of increased consequence in ABF production programs, Main notes.

Beyond segregating pig flows, more records are required at the farm and feedmill levels to document standard operating procedures and protocols. Third-party audits add to the complexity. A number of inventory controls, checks and balances, testing and verification practices must be put in place.

Trials Offer Insight

Main says the venture was a success because it clarified the practical implications of executing the ABF program in this particular production system. It showed that sustainability was most challenging in pigs under 50 lb.

The true costs, potential premiums, and market demand need to be clearly understood before entering into niche markets that require significant input changes, he adds.

About the Author(s)

You May Also Like