Consider cleaning corn to reduce mycotoxin content

While it is common to utilize corn screenings, the results of this study suggest reconsidering the cost-savings of this practice.

August 16, 2017

By Ashton Yoder and Cassie Jones, Kansas State University

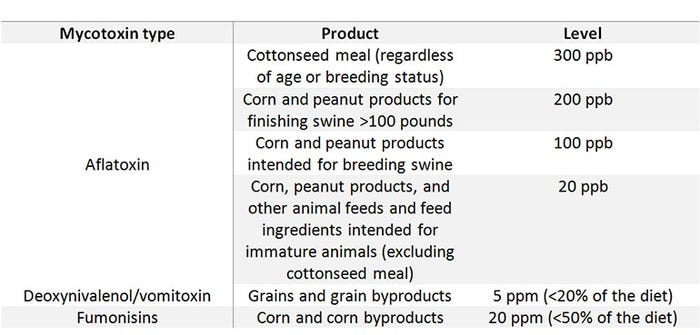

As harvest begins, it is time to again consider activities we can do to minimize the entry and proliferation of mycotoxins into the food and feed chain. There is a Food and Drug Administration guidance for maximum levels of aflatoxin, fumonisin and dexynivalenol or vomitoxin (Table 1). These mycotoxins, in addition to others that do not have guidance from the FDA, may cause illness in swine or impact production efficiency.

Table 1: Summary of maximum levels of mycotoxins in swine feed and ingredients established or recommended in FDA guidance

Ideally, exclusion of mycotoxins during growing or the receiving process would prevent their introduction. Binders have also been demonstrated to increase the level of mycotoxins that can be safely fed to pigs, but are not approved for this purpose by FDA. Thus, additional mitigation strategies are necessary so pork producers have greater flexibility in grain purchasing.

One potential strategy to reduce mycotoxin contamination is to clean corn. The exposed endosperm in these broken kernels may be a substrate for additional mycotoxin production, so removing them may reduce the quantity of mycotoxin in the cleaned corn. Furthermore, screening may reduce contamination located on the outside of kernels. However, there is limited data about the quantity of mycotoxin reduction in corn that is naturally contaminated with mycotoxins.

Methods

We evaluated the role of cleaning to reduce mycotoxins in a single source of naturally contaminated corn. Sixty lots of the corn were cleaned across two different screens using an EBM Gentle Roll Corn Cleaner to isolate clean corn, overs (material >1/2 inches), and screenings (material <3/16 inches). An 11-pound sample of the uncleaned corn, as well as samples from each of the three final fractions were collected from each lot, ground and analyzed for aflatoxin using a quick test (Accuscan Gold, Neogen Corp., Lansing, Mich.) at Kansas State University. Composite samples were analyzed via multiclass liquid chromatography tandem mass spectrometry (LC-MS) at North Dakota State University. Data were analyzed using the GLIMMIX procedure of SAS (Version 9.4, SAS Institute Inc., Cary, N.C.).

Neither the order of screening or number of times across the screen impacted (P >0.05) quantity of mycotoxin removed, so those factors were removed from the statistical model.

Results

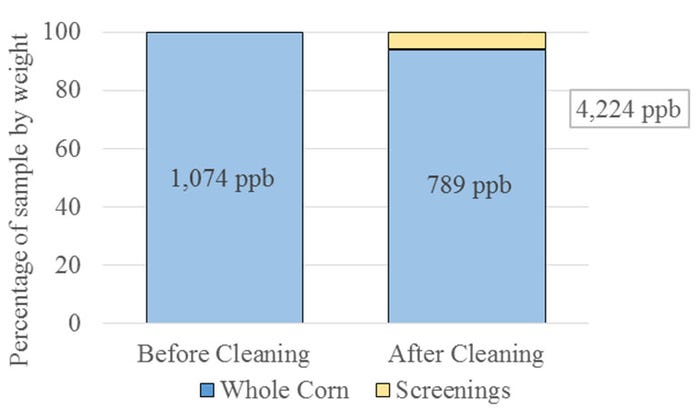

Cleaning generated approximately 6% screenings, and reduced (P <0.05) aflatoxin by an average of 26% (Figure 1; Table 2). Fumonsin was also reduced (P <0.05) by 45%, but did not impact (P >0.05) ochratoxin A or T-2. The ability of cleaning to reduce contamination of some mycotoxins, but not others, may be due to the location of the type of mycotoxin on the kernel itself, or how the toxins attach differently to kernel structures.

Figure 1: Aflatoxin content in corn fraction before and after cleaning

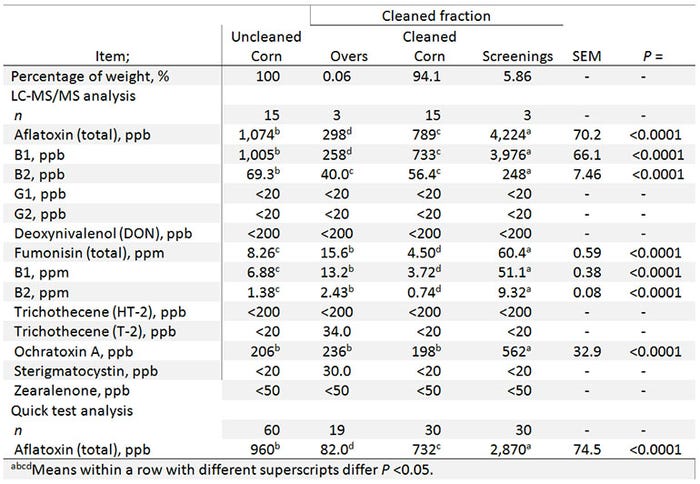

Table 2: Effects of cleaning corn on mycotoxin concentration

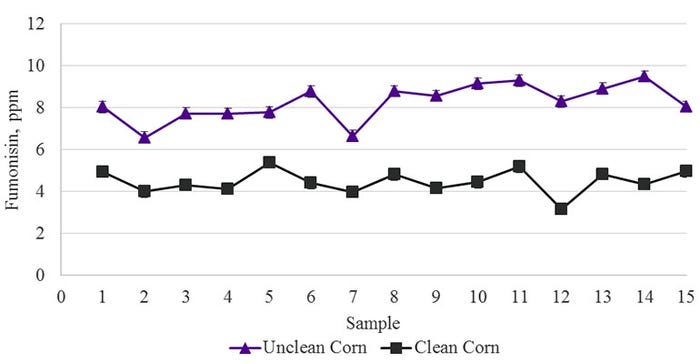

As expected, there was substantial lot-to-lot variation in analyzed aflatoxin (Figure 2) and fumonisin (Figure 3), both before and after cleaning. Still, cleaning consistently reduced aflatoxin and fumonisin concentration in each lot. Screenings had nearly four times the aflatoxin and 7.5 times the fumonisin as the uncleaned corn. This is concerning because it is common to feed screenings, either as a distinct commodity or by addition to the ground corn bin. This practice may lead to high-risk pulses of mycotoxins in swine feed.

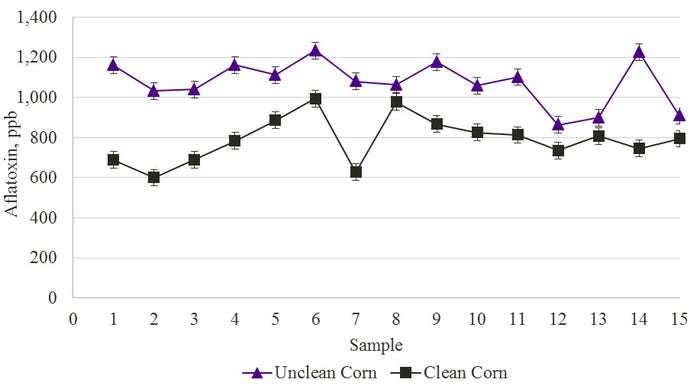

Figure 2: Aflatoxin level in corn before and after cleaning

Figure 3: Fumonisin level in corn before and after cleaning

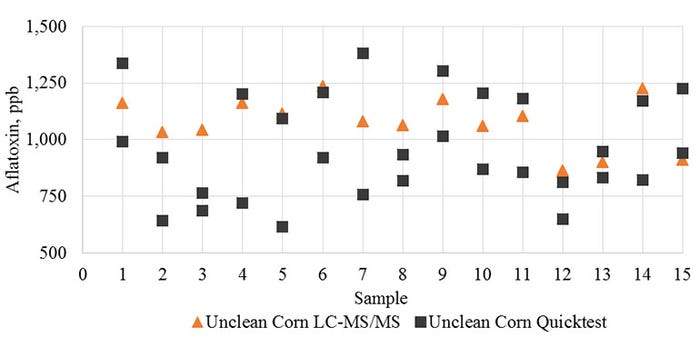

The quick test, which is validated to 150 parts per billion, had variable results within samples (Figure 4). Across multiple lots, however, the quick test method was accurate in uncleaned and cleaned corn. The overall mean aflatoxin level predicted by the quick test was similar (P >0.05) to overall levels from the LC-MS method (960 versus 1,074 in uncleaned and 732 versus 789 parts per billion in cleaned corn).

Figure 4: Aflatoxin level estimated by quick test versus LC-MS in uncleaned corn

However, the quick test method underestimated aflatoxin in screenings (2,870 versus 4,224 parts per billion). This variability in the quick test, especially in screenings, is likely due to the multiple dilutions necessary to estimate high aflatoxin levels in the quick test method beyond 150 parts per billion, as each dilution introduces additional error potential.

Summary

Cleaning corn may be one method to reduce aflatoxin and fumonisin. A limitation of this experiment is that a single supply of corn was utilized, so it is still unknown how these results may extend to corn with less contamination. While it is common for the feed industry to utilize screenings, these results suggest reconsidering the cost-savings of this practice, particularly in years when grains have high mycotoxin contamination.

You May Also Like