Hord farms have steadily grown to the current level of 28,000 sows, but not just for the sake of growth. Each step has been a calculated move with one eye on the future, but also holding true to the past.

May 15, 2018

Hord Family Farms is living proof of the old proverb, “From small beginnings come great things.”

Robert Hord, the grandfather of current Hord Family Farm’s CEO and president, Pat, had been working for a neighboring farmer in the Bucyrus, Ohio, area in the 1940s, during WWII. Robert had two children and was farming, so that combination earned him a draft deferment. With an inheritance from his grandfather, Robert decided to start farming on his own. As a going-away gift, the owner of Blue Goose Farm where he had been working, gave Robert 10 gilts.

“Dad raised those pigs in a wooded lot,” says Duane, Robert’s son and Pat’s father. “From those 10 gilts he sold 82 pigs, which back in the ’40s was pretty amazing.” During WWII, the U.S. government had put a ceiling on hog prices at 16 cents per pound, as lard was being used in munitions. As luck would have it, the 16-cent ceiling was lifted just as those 82 pigs were ready to go to market, and the price jumped to 34 cents per pound, but the elder Hord settled for 32 cents per pound. “That windfall allowed him to purchase his first farm; we still have that farm today and there are 5,000 sows on that farm,” Duane says.

Duane and his father started farming after Guy Hord, the patriarch who purchased his first tract of land in 1905, passed away. Both Robert and Duane worked in local factories until the late-1960s “until they thought that they could farm on their own without off-farm employment,” Pat says.

“My dad’s passion was for raising pigs. He liked to raise corn, but I think pigs was the thing that he enjoyed the most. We probably wouldn’t have looked at the industry as we do today if we hadn’t had someone to teach us the background on pork production,” Duane says.

From those first 10 gilts, Hord farms have steadily grown to the current level of 28,000 sows. This growth hasn’t been just for the sake of growth. Each step has been a calculated move with one eye on the future, but also holding true to the past and the rich Hord family history.

It is for this reason that Hord Family Farms is recognized in this year’s class of Masters of the Pork Industry.

Matt Davis, Hord Family Farms chief operating officer

Matt Davis, current chief operating officer, has seen Hord Family Farms grow since he started 23 years ago in an entry-level position on a 400-sow farm. He agrees that the farm’s longevity, growth and successes are not accidents. “The culture, the family, I tell everybody it’s a great place to work,” Davis says. “They let us do our jobs, and give us the tools to do our job.”

Davis says his time with the Hord family can be measured by years or in sows. “We had 1,000 sows when I started, and now with the new sow farm coming online soon, the system will be at 28,000 sows. … When I started, I don’t think Pat would have put a number of 28,000 sows by 2018, nor will a sow number be put on where the operation will be in five to 10 years. The philosophy from day one is that we’ll continue to grow, but not at the sacrifice of performance. Never lower our expectations or lower our production just to say we gained a few more sows.”

Just as Duane has ridden the changes of the Hord farm, he has seen that evolution mirrored in the U.S. swine industry as a whole, from his father’s 10 gilts raised in a wooded lot to tossing the sows Purina sow cubes in the mud, “then we really got modern when we built a concrete platform where the pigs could come up and eat.”

The farm’s first slatted floor finishing barn was built in 1966. “It was a state-of-the-art, partially slatted building,” Duane says. “Visitors couldn’t believe we were bringing animals inside; it was totally enclosed. The building performed really well, but it was really dirty.”

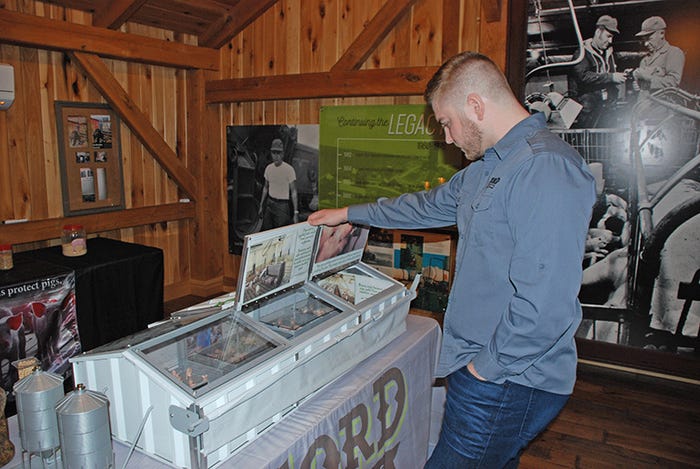

Phil Hord inspects the model of a modern hog production facility that is on display at the Hord Family Farms visitor center. While he attended college, Phil saw firsthand the disconnect that exists between consumers and modern food production.

Producers in the business long enough have all experienced the evolution in everything from feeders and waterers to pens and crates, as well as in housing designs.

Duane credits his dad with being a real innovator when he started using some of the first Caswell farrowing crates. “We could see how many pigs we could save with the farrowing crates. It’s interesting to see how the evolution has gone the full circle,” he says, referring to the first gestation barn the Hords built in 1974, with pen gestation and head gates for the sows where they could be fed. Almost 20 years later, the family built their first crated gestation barn in 1993, before starting to go back to group sow housing in 2008. The Ohio Legislature has mandated that all sows be housed in group pens by 2025.

“I enjoyed the pig business because I knew it was the profit center, I had done it ever since I got out of high school, too. I knew that by doing things in volume and in numbers, there was profitability to it. You need to be in the upper 75% of the producers, and if you could do that, you could still be profitable,” Duane says. “My high school ag teacher always said pigs were the mortgage lifter.”

The Hords also have cropland and a cattle operation, as well as their own feed mill. These are Duane’s passions, and what Pat sees as an important contribution to the operation over the last many years. “Dad has a great ability to take a dream of how to implement a new piece of equipment in the feed mill, draw it up on a blueprint, hire the contractors and make it come to life.” From the beginning, the Hords have been milling their own feed, starting with a nominal number of tons per week and growing to about 5,200 tons per week today at their mill.

The Hord business includes its own feed mill, directly across the road from the visitor center, that mills 5,200 tons a week to feed the Hord hog herd.

“I didn’t want to go forward by myself, I wanted him (Pat) to show me that’s what he wanted to do,” Duane says. “I didn’t want to go out and build him a new barn to see if that’s what he wanted to do. He’s the one who inspired me to do it.”

Duane says his only son came along at the right time. “Not every kid gets to work alongside their grandpa like he did, and he spent a lot of time in the pig farm from the day he could walk. From the time he graduated from high school I could see that was something he was really enjoying, and a lot of it was that it was something he could take and run with himself, a chance to manage his own business.”

In the early 1980s, Duane had built the Hord herd to 300-350 sows. Pat says his dad’s passion was on the crop side, though, and he stressed the importance of diversification. “I started taking care of the pigs in high school; Dad was very supportive,” Pat says. “He went on a trip to North Carolina, and he said we need to go to 600 sows, and I thought, ‘Oh my.’” That 600-sow recommendation was actually built as a 700-sow farm, and that farm is now a 2,400-sow farm.

Hord Family Farms have evolved from the beginning of those 10 gilts to Purina Clean Lean breeding stock to now solely relying on PIC breeding stock.

Although Pat grew up in the hog barns, he became fully invested in the late-1980s, “at a point where a lot of producers were faced with getting bigger into hog production or concentrating on grain farming,” Duane says. “1998 made the decision for a lot of farmers, some saying, ‘This is not what I want to do, I don’t want to manage risk like that.’”

The Hords looked at contract growing that was being done in other parts of the country and questioned why it couldn’t also be done in north-central Ohio.

Pat says locals at that time were familiar with contract growing through a poultry company that had gone out of business. “Early on we had to convince them that this was different. People had confidence in us and what we were doing, and they were doing their own homework,” he says. The first contract building for the Hords was built in 1993, and “all of those first ones but one are still with us today.”

“We appreciate those early contract growers for taking a chance on us,” Pat says. “They took a leap of faith with us. There’s a lot of responsibility when they put up a barn for you, they take out the loan, but they’re dependent on us doing a good job, so I don’t take that lightly. They were willing to take a shot on us, and our family is supportive of making investments.”

Building and maintaining trust

Early in the development of the Hord family’s contract partnerships, it was clear that time and effort would be needed to build acceptance of pig production in an area that was not hog-dense.

“Trust is a huge thing, one of our core values, and there are multiple layers of that,” Pat says. “You’ve got to build the trust; we are always building trust. We look at it like building a bank of goodwill and hope you never have to dip into the bank, but there are times that you have to, and then you have to build it back up. … How you operate, how you treat people. How you treat people with respect. No matter if you disagree, if you treat them with respect. People, in general, want to know that you care and know that you’re listening and hearing their concerns. All of that grows trust.”

One of those first contract growers, Jay Shawk, built Hords’ second contract barn in 1994 while farming with his father at the time. “I made a decision that I didn’t want to be a full-time farmer, and I told Pat that I was looking for something else to do,” Shawk says.

“I told him that if he was going to work off the farm, he might as well come work for us,” Pat remembers telling Shawk.

Shawk started working in the Hord office about 15 years ago. “I wasn’t really sure what I was getting into,” he says. “I was familiar with the family, but wasn’t really sure where they were going.”

Shawk is now director of risk management and nutritional services. So, what was it that got him and his dad to start contract growing for the Hords, and what kept him working for the Hords for so many years?

“It’s 15 years and I’m still here, and I can’t imagine being anywhere else,” he says. “You’re valued, and you’re taken care of, and you’re given the freedom to succeed. To be able to feel fulfilled, you’ve got to have personal responsibility, and you need to feel a part of it.”

That trust extends beyond the walls of the Hord barns and the confines of the operation’s structure. Doug Clemens, chairman, and CEO of Clemens Food Group, says the close-to-three decades’ relationship between his company and the Hords is no accident.

“It’s been a good relationship,” Clemens says. “We’re both seeking a win-win as a producer and as a packer, so we have been dependent on the Hord family’s supply for a very long time, because of A) the quality of their animals; B) the quality of the people who work on their farms; and C) the quality of the family.

“One thing that we’ve always prided ourselves in is looking to partner with people that hold the same values as we do as a company and we define those values like ethics, integrity and stewardship. … the Hord family definitely holds those same values. Very honest people and I see them as a family looking for long-term, not short-term, solutions to help them with their family-owned enterprise.”

All of the hogs from Hord Family Farms are processed through the Clemens Food Group, either at the Hatfield Quality Meats plant in Hatfield, Penn., or more recently at the Clemens Food Group plant in Coldwater, Mich. Pork producers from Michigan had approached the Clemens Food Group about building a pork processing plant in the state to fill the void of Michigan being the only Midwestern state without a facility.

“As we got into it and saw the viability of the project, we saw that it would be required to be a larger scale operation than what the original producer group was looking at,” he says. “We all came to the same conclusion that we needed to reach out to beyond the state of Michigan, and the first people we reached out to was a few producers from Ohio and Indiana, and the Hords were the first people we talked to.” Today, the Coldwater facility processes 8,000 hogs a day, “and certainly the Hord family is a key to that operation,” as are the other 11 producers involved in the plant.

Although he was working on his family’s farm, Shawk felt that he was being held back as to what he could do to “stretch my wings a little bit. That’s the opportunity that I’ve had here, just to learn constantly. … I’ve never worked full time with the sows here, and I’ve never worked full time with the crops, but with about everything else here I’ve done in one aspect or another. … I’ve grown in ways that I would never have anywhere else.”

Shawk sees how the Hord team has grown together over the year, and he truly sees it as a big family. “I can walk up to Pat and challenge him on something, and he knows that it’s coming from something that can make the team and the company better. And if Pat challenges me, I know where it’s coming from. We’re never satisfied with a personal development or production point; we’re always trying to get better.”

Building a strong team is what has made Hord Family Farms successful. From the contract growers to the farm’s employees, or team members as the Hord family prefers, Pat sees them all as integral parts of the operation’s success and an extension of the Hord family.

“You build a strong team by going to everyone’s strengths,” Pat says. “Key team members who have come alongside of us and have been an integral part of any success the business has had.”

Sometimes family and team member intersect, such as Pat Greene, who has been working for Hord Family Farms for 18 years. He had been married to Kim Hord, Pat Hord’s sister, for about a year when another sister, April, was doing chores on a Saturday and, “I went in there and just fell in love with it. It wasn’t my intentions; I was going to school to be a mechanical engineer.”

Pat Greene, Hord Family Farms sow unit manager

So, what was it that swayed the budding mechanical engineer to join the in-laws’ hog operation? “It just felt like it was my calling,” Greene says. “You know how sometimes you know that’s what you wanted to do? I talked to Duane, and he talked to Pat.” He is now manager, and owner of a sow unit, after working his way up from general technician to breeding manager, and then farrowing manager to barn manager. Pat’s sister April, along with her husband, Greg Chance, also are co-owners in another sow farm location.

Greene is excited about the direction of the operation, from Pat Hord’s leadership by concentrating on the people aspect of the farm, “he wants to see everyone have the chance to be somebody more than they are at the time they started here.”

Phil Hord, Pat and Janel’s son, represents the fifth Hord generation in the family business, and he says coming back to the family business wasn’t necessarily a sure bet. He credits his parents with giving him and his three sisters, Colleen, Mallory and Melissa, “the opportunity to do whatever we wanted to do, to use what God gave us skills to do.”

For Phil, that meant pursuing a business degree from Cedarville University in Ohio. “I knew if I didn’t want to come back to the business, I would have that degree to fall back on. Being raised in a business family, I think we look at things differently,” he says. During his junior year in college, Phil realized the opportunity that was in front of him to return home to the family business. “Being the only male Hord of the next generation, some could see that as a lot of pressure, but I never felt the pressure that this is what I had to do.”

Phil has been with the family business since 2015. He oversees assessing and suggesting new technologies that will benefit the company for the long-term.

“We’ve learned a lot about operations, nutrition, genetics; there’s a lot of opportunity for research in these areas. I think we’re just on the brink of figuring out how to truly be innovators in the industry,” Phil says. “I’m so excited for the next 10 to 20 years, so many things that are going to allow us to be more efficient and more productive. We have such a growing population to feed and what country is better positioned to feed the growing world. More people my age are going to need to be involved in agriculture to be able to feed the world.”

Hord Family Farms’ visitor center south of Bucyrus, Ohio, offers the public a glimpse into the Hord history, meshing the past with the present.

Preserving the past, educating the future

The Hord family sees the importance of preserving the past, and to accomplish that the family built a visitor’s center in 2015 that also includes management offices south of Bucyrus.

Visitors can walk through the two-story center located across the road from the Hord feed mill to learn more about the growth of the Hord family and its farming business, as well as the growth and evolution of agriculture. Pictures and various displays aim to educate the consuming public who may be disconnected from how their food is being raised.

The Hords also offer a glimpse into a working hog barn, as five to six years ago they built the Scioto Prairie Sow Farm with a viewing area of the group sow-gilt housing in one barn, and a viewing area of the farrowing room in another barn on the site, in order “to show people what’s going on in the barn,” Pat says. “If we can influence 80 to 90% of them, it’s a win. We’ve learned that we control the things that we can control and release what we can’t.”

Hord Family Farms employs strict biosecurity steps to ensure the safety of the swine herd. The operation has installed viewing rooms on the Scioto Prairie Sow Farm so the public can get an up-close look at the farrowing room without breaching biosecurity protocol. A viewing room is also set up in a different barn on the same farm so that visitors can view the group sow-gilt housing.

Phil’s time in college helped solidify the need to reach out to the disconnected consuming public. He also interned at Fair Oaks Pig Adventure, south of Chicago in Indiana. “We’re not just pig producers, we are food producers, and we need to be able to share that story in terms that people understand because people are so removed from the farming way of life.” He brought a lot of what he learned during his Fair Oaks internship with him back to Hord Family Farms.

While pig production is the backbone of Hord Family Farms, sustainability is key to the operation. Solar panels at the Scioto Prairie Sow Farm are just one example of the measures taken by the business.

Hord Cares

Pat Hord is a business man, but he knows what it takes to be successful: faith, family and the team, in that order.

Hord Cares was established as a way for the growing agricultural entity to begin to give back to the local communities, and to live out their core value of care. Janel Hord, director of administrative services, is actively involved in the financial and pig accounting side of things, but what gets her blood pumping is the mission of Hord Cares.

“That is my passion,” she says. “Several years ago we decided as a management team to develop ways to reach out the community, get more pork out there and also help local charities.” This philosophy is actually building on when Robert Hord began donating ham for the local Relay for a Life cancer fundraising event. “We want to get our great pork out there,” she says, “and we wanted to honor Grandpa Hord.”

The Hords created a pork loin lunchbox fundraiser where local businesses can honor their employees, and as long as five or more meals are ordered, the Hord team will deliver the meals to their business. Last year, more than 1,000 meals were sold. “We started out by reaching out to businesses that we do business with, and word has kind of spread,” she says. Funds raised from the loin lunchbox had been going toward the county Relay for Life, but those funds are now being distributed to other local entities, too.

A couple of such entities that benefited recently from Hord Cares are Flying Horse Farms near Mount Gilead, Ohio, and the Bucyrus Outreach and Resource Network, a local group helping area residents in need. Flying Horse Farms is a camp that “provides magical, transforming experiences for children with serious illnesses” allowing them a camp experience that they would not normally be able to have. Every Hord team member votes each year to decide which entities will benefit from the Hord generosity.

Hord Cares originated as a way to get the good pork out into the community, but has since grown to be “any opportunity to tell our story or show the community we care.” A couple other areas that they have been active in is gathering care packages for local military personnel and Christmas meal bags, which are given around the holidays as a way to “pay it forward” and bring a smile to local families.

Both Pat and Janel are involved on local boards, and they have also recently helped form the non-profit called Crawford Works, which is in the pilot stages to connect employers with willing and able job seekers in the Crawford County area. “We have some people who are stuck in generational poverty, they just don’t know how to get out of it, and the only way we know how to combat that to help them is through work,” Pat says. The couple has underwritten the program, and Pat sees it as an intersection of the family’s faith and business. “I believe the Bible teaches that you should help those in poverty, so we like to give someone a hand up through employment mentoring instead of just a handout,” he says. “Kind of like the old saying of, ‘Give a man a fish, and you feed him for a day. Teach a man to fish, and you feed him for a lifetime.’”

Robin Davis, Hord Family Farms chief people officer, sees the Hord Value Tree as far more than a neat figure and motto on the wall and the website. She sees it as the way the Hord team operates, from the top down. “That truly is the way that we work around here,” she says. “It’s the way we live and work, if you try to fake it, people will see through that. And if you try to fake it, it’s not going to work.”

Obviously, Pat sees the importance of the investing in the business, but more importantly he sees the value of investing in people. “We are doing our best to steward the business by following Christ as we care for one another and look for ways to serve others,” he says. One example of this is how they recently decided to hire “Market Place Chaplains” to support their team. Everyone goes through challenges with health, marriage, children, finances, etc., and it is nice to have someone unbiased to help talk through some of those things. Another way they give team members the tools for a better life is by sponsoring them to go through Dave Ramsey’s Financial Peace University. “We really like the idea of supporting our team with personal financial training,” Pat says. “We try to act like a family around here. … So, investing in the farm is important, but it is just a tool that can be used to make a difference in the people and community around us.”

Phil sees the strong heritage he has to uphold that started with Guy Hord and had trickled down to his father. “There’s never been a day where I felt like he wasn’t dedicated to get better and continue to improve. I think that started way back with my great-grandpa, and to my grandpa, I think it’s in our DNA to continually get better. If we lost that, that would definitely be a big difference in how we do business and how we operate, but if you’re able to maintain that ‘we haven’t arrived’ mentality, that we are constantly improving and dedicated to that mindset each day. He has been able to instill that from top down to the team.”

As with any business, there are growing pains, and Hord Family Farms is no different. “We went from having five pigs born every day to having more than 2,000 pigs born every day today, and you don’t get that done without a fantastic team,” Pat says. “I have been blessed to have a very engaged team that has high expectations for themselves. I’ve been really fortunate to surround myself with people strong in areas that I am not strong in.

“This isn’t about me, it’s about us as a family, about us as a team.”

You May Also Like