Geothermal Design Banks on Tempered Air

Agricultural engineers at the University of Minnesota have spent the better part of a year capturing a snapshot of the energy-saving capabilities of a one-of-a-kind, 900-sow, breed-to-wean facility fitted with matching sets of five geothermal heat exchangers on both sides of the structure. The relatively simple design allows outside air to be pulled through each of 10 heat exchangers to temper air (heat in winter, cool in summer) as it enters 8-ft.-wide hallways that serve as inlet air-mixing chambers.

August 15, 2012

Agricultural engineers at the University of Minnesota have spent the better part of a year capturing a snapshot of the energy-saving capabilities of a one-of-a-kind, 900-sow, breed-to-wean facility fitted with matching sets of five geothermal heat exchangers on both sides of the structure. The relatively simple design allows outside air to be pulled through each of 10 heat exchangers to temper air (heat in winter, cool in summer) as it enters 8-ft.-wide hallways that serve as inlet air-mixing chambers.

Controllers for each room open and close air inlets that allow tempered air to be drawn into the rooms. Hot-water, fin-tube radiators provide supplemental heat to further warm the air coming into farrowing and nursery rooms, as needed.

In its entirety, the all pre-cast concrete structure at the Lismore Colony farm near Clinton, MN, features two, 300-sow gestation rooms, two gilt housing rooms (one with stalls, another with open pens), 10 farrowing rooms with 18 crates each and eight nursery rooms divided into four large pens. Manure is collected in shallow pits about 30 in. deep, with pull plugs in all rooms. Manure is transferred to a sump where it is pumped to an adjacent pre-cast 204 x 204 x 12 ft., above-ground, covered concrete storage tank that holds 3.5 million gallons of manure. The farm, managed by Jeremy Wollman, is a gilt multiplication unit for Genesus. Purebred Yorkshire gilts are mated to Landrace boars to produce F-1 females.

The heat exchangers, positioned along the outside walls of the hallways, resemble oversized radiators. Each is equipped with a variable frequency drive 1.5-hp. water pump that circulates propylene glycol (common RV antifreeze) through 32 thermal loops that enters the exchanger and descends 250 ft. to the bottom of a 5-in.-diameter well, where it loops back up to complete the cycle. In all, 320 wells were drilled in a grid, 12 ft. apart.

Extension agricultural engineer Larry Jacobson and research associate Brian Hetchler collected temperature and air quality data during seven, 24-hour sampling periods spanning an every-other-month schedule to try and cover seasonal effects. The facility began operating in early 2009, and the first air monitoring was done in November 2010. The final samples were obtained in November 2011.

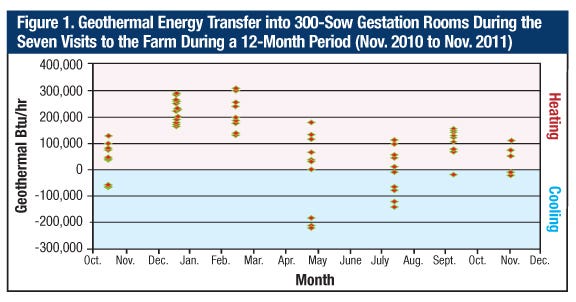

Figure 1, shows the ranges of heating and cooling energy during the seven, 24-hour monitoring sessions. Air samples were taken at 3-hour increments, starting around midday the first day of each site visit, with two more samples taken at 4-hour increments during the morning of the second day. Air samples were collected into 10-liter Flexfoil bags, as well as temperature and humidity measurements gathered from the exhaust airstreams from six rooms (two gestation, two farrowing, two nurseries). In addition, one sample was collected from air inlets in each of the east and west hallways.

The chimney-styled ventilation system, designed by Dutch-based Installation Technology Boxmeer (ITB), has variable-speed fans that exhaust air through the roof. A unique feature is a calibrated, two-speed counter fan that measures airflow rate, making it easier to capture airflow data as well as the run times for additional ceiling-mounted exhaust fans operated during warm weather.

Air samples were analyzed on-site for ammonia (NH3), methane (NH4), carbon dioxide (CO2) and hydrogen sulfide (H2S).

The original research project was amended to also measure odor and total suspended particulates (TSP) or dust during the January, May and September sampling periods. Duplicative odor samples were collected during one of the six sampling periods of each site visit and returned to the university’s olfactometry laboratory for odor analysis by a trained panel.

Dust samplers, mounted near the chimney ventilation system in a gestation, farrowing and nursery room and a hallway, operate on a timer to collect particulate matter for a specified period of time (i.e., 24 hours). Before and after weights of the filter determine dust levels.

Armed with concentration data for gases, odor and dust coupled with air flow rates, emission (flux) rates were calculated. Farm records, coinciding with sampling periods and barn conditions, were analyzed to determine geothermal effects on sow performance.

Heating/Cooling Effects

“The goal of the company designing the system (ITB) was to balance the heating and the cooling. Whatever heat they put in the ground in the summertime, they wanted to extract in the winter,” Hetchler explains.

“They actually cool the ground temperature in the wintertime because they are extracting heat, then they put heat back in the summertime,” Jacobson reinforces.

“There’s a small zone around each of those wells where the soil temperature will fluctuate up and down a little. But, at 250 ft., the soil is saturated, so heat and cold are easy to transfer,” he adds.

The soil temperature around the buried tubing is a relatively static 50°F., except for the top 10 ft. of soil.

In the study, researchers focused on the two gestation rooms because neither had non-geothermal supplemental heating or cooling sources.

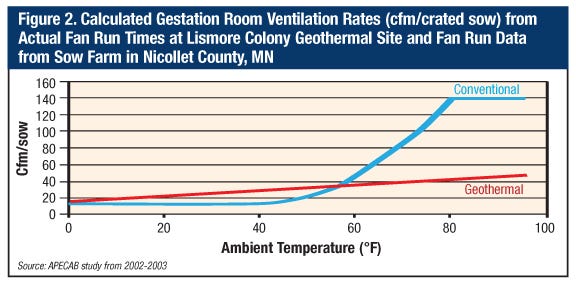

Ventilation rates (cfm/sow) for the 12-month monitoring period in the two gestation rooms were compared to data from “conventional” sow gestation barns in southwestern Minnesota, which were monitored in 2002-2003.

The first measurements were taken in a colder-than-normal March (2011), when outside temperatures dipped below freezing but hallway temperatures held at about 50°F. “The geothermal system delivered between 200,000 and 300,000 BTU/hour of heat to the 300-head gestation barn (Figure 1),” Jacobson points out. “Fans were providing the minimum ventilation, so with low air flows the temperature rise of the incoming air was relatively high (20 to 30°F).”

Figure 2 shows a large difference in airflow rates as a function of outside (ambient) temperature. “Most obvious is the very significant reduction in the barn’s ventilation rate (in the geothermal unit) during periods of warm-to-hot outside temperatures,” he explains. “You just need enough air exchange to get rid of the moisture and maintain air quality and CO2 levels, which is 40-50 cfm/sow. Lo and behold, we were measuring 50 cfm/head in this geothermal gestation room,” he adds.

“During the wintertime, we can keep the breeding-gestation rooms at 72°F., at minimum ventilation rates,” Wollman explains.

Cooling rates are expressed as “tons of cooling or tons of refrigeration” and translated into BTUs/hour (Figure 1), similar to common measures of heating, explains Hetchler. Interestingly, the “tons of cooling” measurement is a holdover from the days of ice block cooling, which is defined as “the cooling capacity of 2,000 lb. or 1 ton of ice.” One ton of cooling is equal to 12,000 BTU/hour. For perspective, a standard home air conditioner provides about 1.5 to 2.0 tons of cooling.

In the 300-sow gestation rooms, on an average (85°F. maximum) July day, “we were seeing 15 to 18 tons of cooling per room provided by the geothermal system,” Hetchler notes. In addition, the geothermal system condenses some of the humidity out of the air as it passes through the radiators. This water is collected in large trays at the base of each radiator.

“Not only are we reducing the dry bulb or sensible heat, we are removing a lot of moisture — and that is huge!” Jacobson proclaims. “You can’t do that with evaporative cool cells — they actually add water (to the air).”

Air Quality

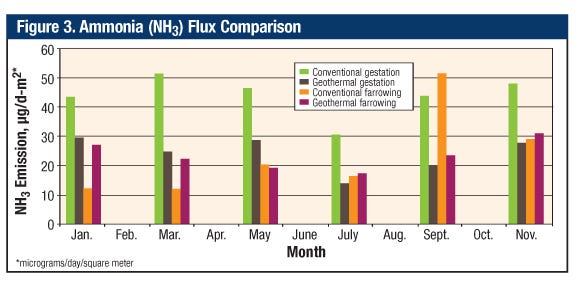

Figure 3 shows the emission or flux rates for ammonia (NH3) from the Lismore Colony farrowing and gestation rooms. To provide a comparison with “conventional” facilities, researchers turned to data from a 15-month Aerial Pollutant and Emissions from Confined Animal Buildings (APECAB) project conducted in 2002-2003. That sow gestation unit was located in southern Minnesota and the farrowing facility was located in central Illinois. The sites had similar pull-plug manure handling, gestation stalls and farrowing rooms.

As the graph shows, NH3 emissions from gestation rooms followed the same general trends throughout the seasons, although the geothermal facility consistently had 20-30% less.

Interestingly, NH3 emission rates from farrowing rooms in the Lismore Colony unit and the conventional farrowing unit responded differently. Emissions from the geothermal farrowing rooms dipped in the summer months (May, July), while the APECAB test barns spiked in late summer and early fall. Researchers attribute the summer reduction to the cooler temperatures in the geothermal barn.

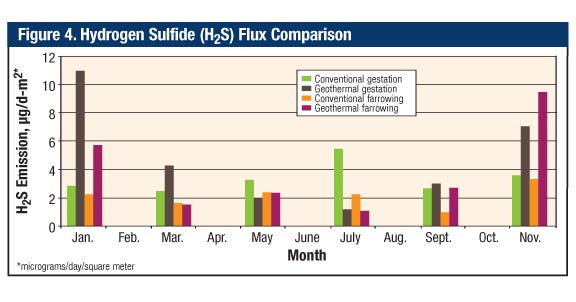

The emission or flux rates (mass/area) for hydrogen sulfide (H2S) were relatively high during cold months and then subsided in summer months in the geothermal unit (Figure 4). Those rates showed opposite trends in conventional barns — higher in summer, lower in winter.

Geothermal farrowing rooms followed the same trend, while H2S emissions from conventional farrowing rooms did not vary much by season. Researchers found no apparent reason for these differences, but speculated that differences could be related to sow diets, pit additives or frequency of pulling the plugs.

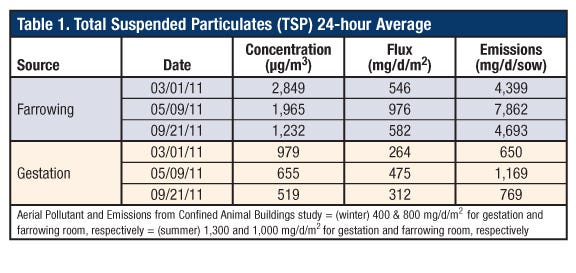

As noted earlier, particulate matter (dust) and odor were sampled during three of the seven sampling periods. Total suspended particulates (TSP) are sometimes referred to as “total dust” (Table 1). Generally, TSP levels at the geothermal site were lower than those measured at the APECAB sites in gestation and farrowing rooms.

“Typically, warmer weather produces greater dust emissions, primarily due to the high ventilation rates seen in conventional buildings,” Jacobson notes. “It seems logical that with greatly reduced summer ventilation rates that we found in the geothermal site, this would at least partially explain the reduced dust levels.”

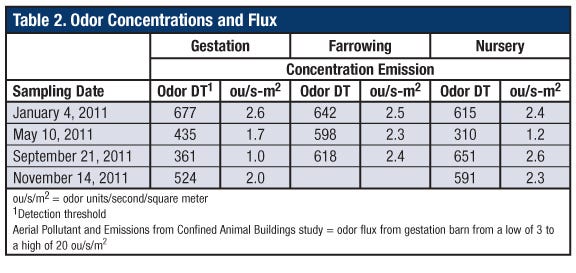

Likewise, odor concentrations and emission rates, measured in odor units/second/square meter (ou/s/m2), were lower in the geothermal unit rooms than those found at the APECAB sites (Table 2). The geothermal units ranged from just 1.0 to 2.6 ou/s/m2, while the APECAB facilities ranged from 3.0 to 20.0 ou/s/m2.

“The reasons for the low odor concentrations in the gestation rooms were that we were moving a lot less air and the fact that it was cooler, so microbally, everything is less active,” Jacobson explains.

Tracking Energy Use

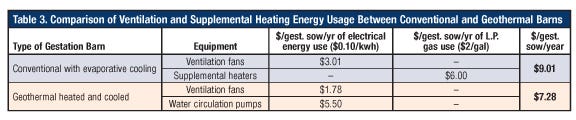

To estimate the energy used to operate ventilation exhaust fans, assuming fan energy efficiency of 17 cfm/watt, the total ventilation fan electrical energy used was 17.8 and 30.1 kwh/gestating sow/year for the geothermal rooms vs. conventional barns, respectively (Table 3).

The electric water pumps circulating the fluid through the geothermal heat exchangers and the 250-ft.-deep wells were estimated to require 30% of the energy consumed in the two Lismore Colony gestation rooms — roughly 33,500 kwh/year (55 kwh/gestating sow/year). In comparison, the supplemental heaters in a 1,400-sow, farrow-to-wean, conventional facility used about 8 gal. of liquid propane/sow/year in both farrowing and gestation. Therefore, if half of that propane was used in gestation, the energy used would be about 3 to 4 gal./sow/year.

“In the summertime, we just needed to move about 50 cfm/sow in the geothermal unit, but in a conventional barn you would need about three times the amount of air, up to 140 cfm/sow. The cost to run the fans in the geothermal unit was about half what it cost to run the fans in the conventional barn ($1.78 vs. $3.01),” Jacobson explains.

The researchers estimated that at 10 cents/kwh, the fluid circulation pumps cost about $5.50/gestating sow/year to operate — a bit higher than they expected. Some design changes, such as eliminating the sharp corners in the radiator plumbing, could improve the efficiency of the pumps.

Cost/Payback

The estimated capital costs of adding the geothermal system to the Lismore Colony breed-to-wean facility was about $400,000.

In terms of a simple payback, it is estimated that a savings of $1.75/sow/year could be realized with the geothermal system. “Some of the energy use in the geothermal barn should be attributed to barn cooling in the summer,” Jacobson notes. “This economical cooling capacity is one of the main advantages of using geothermal because of the (positive) impact on animal performance, particularly through the hot summer months.”

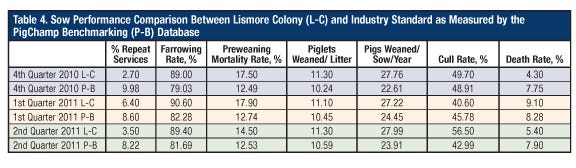

The sow performance data (Table 4), Lismore Colony (L-C) vs. industry standards from the PigChamp benchmarking (P-B) database, include common measures of reproductive efficiency, such as pigs weaned and sow culling rates.

“In the coldest part of the winter, the temperature in the hallways will drop to 36°F.,” Wollman explains. “And in the hottest part of the summer, when it’s 105°F. outside, the hallway temperature will barely come up to 75°F. The highest temperature in the breeding/gestation rooms reached 83°F.”

Even during the extreme hot spells experienced in August 2011, conception rates and farrowing rates held steady and pigs weaned/mated female/year (PW/MF/Y) were running 3 to 5 PW/MF/Y better than the PigChamp benchmarking database averages.

According to the Genesus Herd Performance Monitor records for a 14-month period between May 1, 2010 and June 30, 2011, the farm recorded a farrowing rate of 90.9%, averaged 15.66 pigs born/litter (13.52 born alive/litter) and 27.81 PW/MF/Y.

Jacobson estimates the vertical geothermal design utilizing the deep-well concept used at the Lismore Colony site costs 20 to 40% more than a horizontal geothermal design.

“If you’ve got a big footprint, it’s probably cheaper to go with the horizontal design. If you have 10-12 ft. of clay soil that is fairly moist and has a lot of heat capacity, I think the horizontal design will perform as well as the deep well system, if it’s designed right. With sandy soils that dry out easily, the heat transfer is not as good and you won’t have as much capacity,” he explains.

Jacobson sees a real opportunity for this ventilation/geothermal technology to be used in filtered gestation barns. “This geothermal barn would have a minimum (ventilation) rate of 12 cfm/sow and an estimated maximum ventilation rate of 50 cfm/sow,” he notes. “In a typical filtered gestation barn, the maximum ventilation rate is 250-300 cfm/sow, so with geothermal cooling, the barn’s ventilation rate and filter costs are reduced by 75-80%.”

You May Also Like