Capitalizing on manure’s nutrient value

Research shows the use of More Than Manure Nutrient Manager reduces ammonia emissions by an average of 10%

Nutrient management is always on the mind of Pennsylvania farmer, Bob Buser. Farming in the Chesapeake Bay watershed adds a new layer of challenges with government regulations establishing strict criteria for manure management.

In 2010, the U.S. Environmental Protection Agency established the Chesapeake Bay Total Maximum Daily Load – a comprehensive “pollution diet” for the 64,000 square-mile watershed. This TMDL is unique because it sets an extensive measure by the EPA that’s comprised of pollution limits and strict regulations on land activities including farming. This historical TMDL moved the effort to improve water quality from voluntary best management practices to regulatory for Delaware, Maryland, New York, Pennsylvania, Virginia, West Virginia and the District of Columbia.

For Buser and all farmers in the watershed, it means additional restriction on common farming practices such as manure and commercial fertilizer application. According to the EPA, the TMDL set Chesapeake Bay watershed limits of 185.9 million pounds of nitrogen, 12.5 million pounds of phosphorus and 6.45 billion pounds of sediment per year.

On the Buser family farm, his brother's hog operation supplies necessary organic nutrients for his 1,400 acres of hay, corn, soybean and wheat. Utilizing the manure from 8,500 hogs is a win-win for this family farm. The task of handling the manure is never a job that many will eagerly volunteer to tackle.

Searching for a better way to handle manure while getting the most out of the nutrient value, Buser took a chance two years ago on a Verdesian Life Sciences product, More Than Manure Nutrient Manager. He admits he has always been the adventurous type and likes to conduct experiments on the farm to find solutions that improve the productivity and profits of the farm.

Aaron Hunsinger, Verdesian Life Sciences technical sales representative, says the MTM is an easy product for livestock producers to use. The liquid can be applied directly to the manure pit, lagoons or across the fields.

Testing the product

In the first year, Buser added the product to every load in the manure spreader to fairly evaluate the MTM. Immediately, he admits seeing positive results on his wheat fields with yields reaching over 100 bushels per acre for the first time. Buser, also notes that particular growing year had a very dry May and he was quite concerned about the wheat crop.

Buser’s experience with the product is exactly what the product was designed to do, Hunsinger explains. He says, “MTM is meant to keep the nutrients in the manure for the crops you are planting. So, it keeps the nitrogen from volatilizing and denitrification or leaching. It also keeps phosphorus available for the crop.”

Buser adds that the availability of the nitrogen and phosphorus for the entire growing season has improved yields. Comparing split application, the family’s corn crop yields eight to 10 bushels higher in the field where manure treated with MTM was applied versus non-treated manure. Moreover, depending on the crop some nitrogen is held over from growing season to growing season.

Reducing nitrogen and phosphorus runoff is important to all farmers but especially to farmers under close scrutiny by the EPA. Soil testing is a normal part of Buser’s farming practices. On the average the family runs 100 to 150 soil samples a year. Based on the regulations set by the TMDL, Buser cannot apply manure or any fertilizer on any fields exceeding limits set by regulation. In fact, the hog manure produced on the farm is meeting all the fertilizer needs for the crop side of the farming operation which is a money saver for both sides of the operation.

Seeing the value of MTM, Buser switched to using the product in his manure pits. The family hog farm operated by his brother consists of two buildings with manure pits directly below the pigs. Like many hog farmers, removing solid manure is a major problem. While the sludge is denser with nutrients, it can be difficult to handle. MTM makes the manure more consistent, allowing for easier pumping and field application.

The Buser family has tried other products in the past to reduce odor while spreading. Based on the farm’s experience, they could never get the manure spreader completely full and spent a great deal of time waiting on foam to dissipate. This was not the case when Buser used the MTM product. The manure was consistent texture which meant he was able to get more gallons per load out, saving time overall. What’s more, Buser is able to empty his manure pit below 3 inches which was not possible in the past.

Friendly to the nose

From an environmental standpoint, an added bonus is that MTM lessens the manure smell. As the nitrogen volatilizes, it brings up other gases odor which reduces the normal unpleasant smell that people typically complain about. Hunsinger points out that the individual handling the manure will not notice the odor difference, however it will be less bothersome to neighbors.

Buser also notes the odor reduction benefits the pigs and people. MTM was only used in one of the two pits on his farm to further evaluate the product at first. A field representative from a company that he contracts the pigs from, instantly noted the difference in odor in the two buildings while checking the pigs. The representative asked what was different between the two barns. The only change in management practice between the two buildings was the use of MTM in the pit.

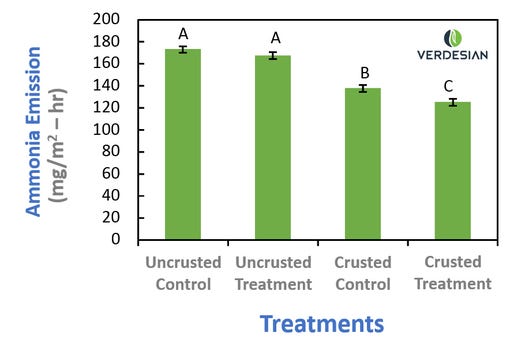

In collaboration with Iowa State University researchers Daniel Andersen and Jacek Koziel, Verdesian Life Sciences recently conducted research to determine the effectiveness and rate at which ammonia emissions could be reduced in storage. This study concluded that with the use of More than Manure Nutrient Manager, ammonia emissions were reduced on average by 10% (see figure below).

According to the ISU research team, treating the swine manure with MTM significantly reduced ammonia emissions (p = 0.0003) for both the crusted and un-crusted manure. In addition, though not statistically significant, the study results showed that manures treated with MTM had lower hydrogen sulfide emissions and lower emissions of key odorants like Cresols, Indoles and n-Butyric acid, especially when treating solids-rich, crusted manure. Furthermore, Andersen and Koziel conclude that MTM was just as effective from the moment it was added through the six months of storage. This means less ammonia odor from the barn and more fertilizer value in the manure when it comes time to use it.

Learn more about More Than Manure Nutrient Manager.

About the Author(s)

You May Also Like