Sometimes, it gets worse. The showers that moved through Iowa and other Corn Belt states last weekend missed more acres than they hit. And the “it-might-save-the-soybeans“ refrain about late-season rains is beginning to ring hollow, too.

July 30, 2012

Sometimes, it gets worse. The showers that moved through Iowa and other Corn Belt states last weekend missed more acres than they hit. And the “it-might-save-the-soybeans“ refrain about late-season rains is beginning to ring hollow, too.

Rain would still help, but the news and the market psychology continue to get more negative as new crop corn futures hit new, all-time highs this morning. Soybean and soybean meal futures are making a run toward the highs that they set last Monday.

The driver, of course, is more and more evidence that both corn and soybean yields will be lower than USDA’s July estimates. In the case of corn, actual yields could be much lower than 147 bu./acre, with many forecasters dropping yields to near 130 bu./acre. At least one prognosticator is predicting a yield in the low-120-bu./acre range.

Some of these estimates are based on actual surveys, much like USDA is doing right now in preparation for the Aug. 10 Crop Production and World Supply and Demand Estimates (WASDE) report. Plant numbers, ear numbers, row numbers, kernel counts, etc. will be the ultimate determiners of yields and these most recent – and dismal – forecasts are based on those “objective” data. It doesn’t look good.

Options to Save More Feed

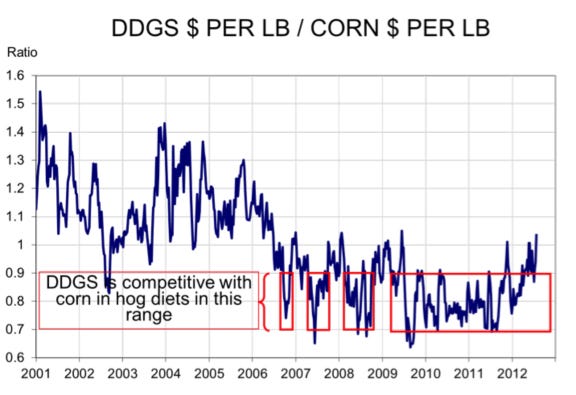

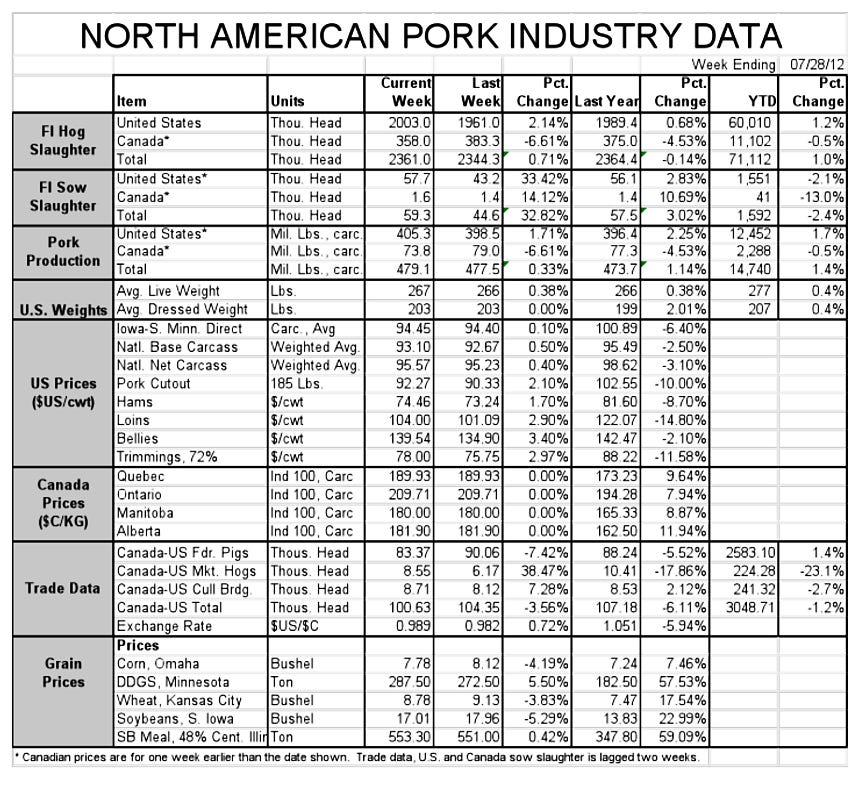

So the question arises again, “What can be done?” Everyone is already using “alternative feed ingredients” as much as possible. Distillers’ dried grains with solubles (DDGS), the feed savior that has been so “graciously” offered by the ethanol industry is becoming more and more expensive relative to corn (Figure 1). A driver in that price relationship is DDGS and its relatively high protein content is now being priced as a replacement for soybean meal. DDGS availability will be an ongoing challenge as ethanol plants reduce or cease production due to negative margins. But use it where you can to the greatest extent that you can!

Another answer is to redouble your efforts to save feed now. That’s difficult to do when you’re already focused on using feed efficiently, but here are a few ideas that may help:

· You already feed sows the most efficient amount of feed to produce a large, healthy litter, but double-check sow body condition to eliminate over-conditioned sows. While you once could not afford body scores of “5,” now you may not be able to afford scores of “4.” Just four ounces less feed per sow per day will save 50 tons of feed in a 1,200-sow operation and leave 1,400 bushels of corn in the bins.

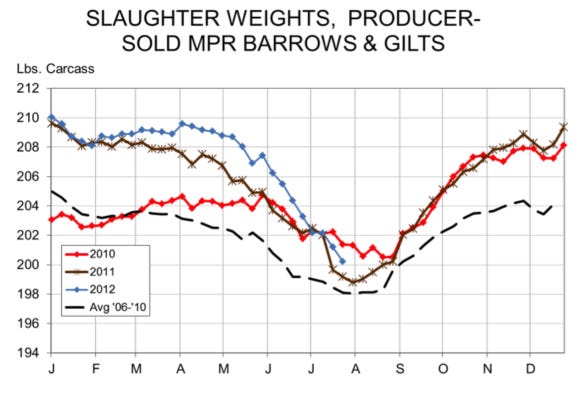

· Consider reducing market weights. Hot weather and lower-energy diets may have already accomplished this, but the issue is what you do going forward. As Figure 2 shows, producer-sold barrow and gilt weights have plunged at a faster-than-normal rate since June 1 and were only 1 lb. heavier last week than they were a year ago when we were in the middle of the short-lived but intense heat wave of 2011. But late-July and early-August almost always mark the seasonal low for hog weights.

· Generally, September sees market weights increase as temperatures fall and new-crop corn becomes available in some areas. That does not have to happen if producers are aggressive in marketing hogs. There is space in packing plants right now for more hogs. Based on the June Hogs and Pigs report, I don’t think packing capacity will become restrictively tight this fall. But it will still get tighter if pigs move at a normal, seasonal pace. That natural tightening will mean that producers will not be able to do much about market weights when the calendar turns to October! If weights are to be reduced, producers must be aggressive in selling now.

· Marketing pigs at lighter weights will save tons of feed – a benefit to individual producers and the industry as a whole. Yes, hitting packers’ weight requirements will be difficult. The challenge here is to keep as many hogs above the minimum as possible while eliminating the pigs over or near the top of the range. Accomplishing this goal will require more accurate sorting and thus most likely, more labor. But which is in shortest supply – labor or feed? Which cost has gone through the roof – labor or feed? Producers should be able to afford more labor due to feed costs savings. Just how much more labor is a key decision variable. There are no pat answers.

Figure 1:

Figure 2:

About the Author(s)

You May Also Like