High-performance hog facilities a top priority

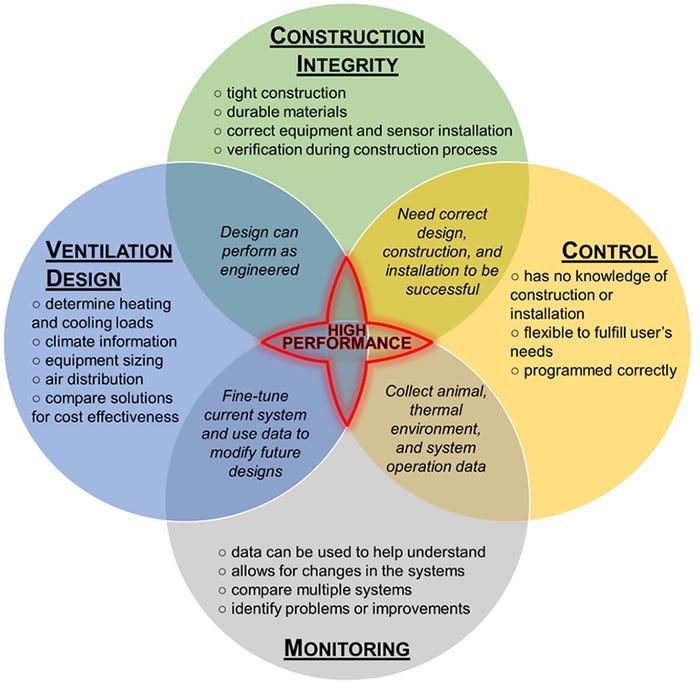

To create a facility that performs at the level our pigs and producers desire, we must improve and unify ventilation design, construction integrity, control and monitoring.

March 22, 2017

By Brett C. Ramirez, Iowa State University Department of Agricultural and Biosystems Engineering Graduate Research Assistant

Swine production has experienced many important and critical advancements over the last few decades; however, facility performance, from a ventilation perspective, has not yet reached its highest level. The indoor environment can help ensure that the advancements made in nutrition, genetics, animal health, etc., are not marginalized.

Engineers can use the ventilation system to help supplement those advances, if they are allowed to perform their role in collaboration with nutritionists, veterinarians, well-being specialists, etc. While there are novel ventilation technologies, equipment and designs constantly under development to help boost the performance of our facilities, rarely do all these components exist together in harmony. Thus, the frequent result is poor performing facilities.

Most of these facilities often share many similar problems and has also allowed for complacency with our ventilation systems. There is a noticeable gap between ventilation system design, construction integrity, technology in controllers and data management — and it continues to grow. This column aims to highlight some key areas where engineers can help create high-performance facilities that improve animal performance, reduce environmental impact and decrease the impact of seasonal variability through uniting design, construction, control and monitoring.

Ventilation design

The heating, cooling and ventilation system design must be engineered correctly during the design phase of the facility. Correct ventilation system design requires engineering the entire path fresh air must travel, from exterior secondary inlets, through primary planned inlets and to the exhaust. It also includes calculating required open areas for evaporative coolers and selection/sizing of other mechanical equipment (such as heaters).

This aspect of the facility design must be synchronously integrated with the design of the other facility components, such as pen layouts, feeder placement, etc. By simultaneously working on the different components of a facility, each discipline can contribute their strengths and work together to create a facility that yields the most benefit to the animal. When ventilation design is not integrated into the facility design/layout from the beginning, any errors or oversight can be amplified and propagated through to when the building is stocked and operational. Problems often include under- or over-sized fans and/or poor inlet sizing and layout. Many common problems are attributed to poor design or layout interferences and often challenging to fix once the facility is operational. Good ventilation design needs to be emphasized and concurrently integrated with other aspects of the facility design.

Construction integrity

As highlighted in the previous column, air infiltration through ceiling/wall joints, pit covers, shutters, doors, building shell, curtains, etc., can disrupt fresh air distribution at the low ventilation rates commonly used in the winter. Air entering the room through planned inlets requires sufficient static pressure across the inlet to generate rotary airflow patterns in the room and replace old air with fresh air within the animal occupied zone. Infiltration makes it almost impossible to achieve the static pressure needed to accomplish this.

For a ventilation design to function as it was intended, the building must be well-constructed with minimal infiltration. Another aspect of construction integrity includes the placement/installation of equipment such as lights, inlet machines, feed tubes, etc., on the ceiling. When these items are placed in front of inlets, the function and performance of the ventilation system suffer greatly. To correctly engineer the ventilation system, a jet throw (horizontal distance the air will travel along the ceiling) must be assumed using the type of inlet, static pressure across the inlet and air flow through the inlet. This jet throw is used to ensure fresh air is distributed throughout the building and no dead air spaces develop; however, if there is equipment installed directly in front of the inlets, it is impossible to achieve the jet throw needed to deliver fresh air.

Control

The function of the controller is to manage the mechanical systems and provide a stable and uniform thermal environment inside the room. Since this is the final component in the ventilation system, the performance of the controller is completely dependent on the equipment selected, installation of that equipment and its configuration. This essentially means, regardless of controller cost or sophisticated technology, the controller will be unable to perform at its highest level or the way it was specifically designed to operate, when the ventilation system is designed wrong and/or installed poorly.

The controller has no knowledge of the equipment, installation of equipment or other features in the room that could impact the environment. Hence, the system must be designed and installed correctly to give the controller the best chance at providing a suitable environment. Further, a controller is only as good as it is programmed. That is, a poor initial setup or frequent setting changes can severely inhibit the ability of the controller to function properly.

Monitoring

The best feedback for assessing animal comfort and performance of the system is the environmental conditions in the room and pig behavior. Data recording capabilities in modern controllers have substantially advanced in recent years creating a new realm of ventilation system “big data” available in the cloud. A shift beyond manual recording of daily high and low temperatures could provide new insight on designing and controlling facilities.

A unique opportunity may exist to custom calibrate or fine-tune every facility based on continuous temporal and spatial data inside a room. Data could also be used to identify and troubleshoot equipment issues or improve regions inside the building.

A strong connection between design, construction, operation and monitoring must exist — with each complementing the other to provide the best environment possible for pigs with minimal resource usage. If any aspect of the whole ventilation system (from design to operation) is incorrect or inadequate, it becomes nearly impossible to house the animals in a high-performance facility. Engineers must be allowed to perform their role, in collaboration with nutritionists, veterinarians, well-being specialists, etc., in helping to create high-performance, sustainable and economic swine production systems.

To create a facility that performs at the level our pigs and producers desire, we must improve and unify ventilation design, construction integrity, control and monitoring. The disconnect between building ventilation and the advancements in nutrition, genetics, animal health, etc., needs to be resolved. A more interdisciplinary approach that includes high-performance facilities will be needed for the future.

The next column will discuss potential uses of monitoring data to help improve environmental control.

You May Also Like