Determining the productive energy of corn germ meal

There is considerable variation between literature estimates of the energy content of corn germ meal, as well as between estimates of productive energy content from growth experiments carried out by researchers.

February 2, 2017

The swine industry is always looking for ways to reduce feed costs, which are the largest costs involved in producing pigs. One approach to reducing feed costs is to use byproducts such as corn germ meal, which comes from the corn wet milling industry.

CGM is an alternative source of energy and protein that can be used in swine diets. However, there is little-published information on the use of this ingredient in swine feeding programs.

A more accurate energy value of CGM or any feedstuff is essential to decide on whether or not it is economically viable to include the ingredient in the diet. The inclusion of alternative ingredients could result in more cost-effective diets for pigs.

The concept of productive energy originates from concerns that published energy values for individual feed ingredients are not accurate and need to be validated and/or adjusted based on growth assays. This is particularly the case for high-fiber ingredients such as CGM that traditionally have not been widely used in swine diets.

Finite details

A research team from the University of Illinois, in collaboration with The Maschhoffs LLC, conducted two wean-to-finish growth studies to determine the productive energy of CGM by correcting metabolizable energy estimates for caloric efficiency (calories consumed per unit of weight gain) relative to a typical corn-soybean meal-based diet.

Both studies used a randomized complete block design and evaluated CGM inclusion level: 0, 12.5% and 25% in Study 1; and 0, 10%, 20%, 30% and 40% in Study 2. The CGM was from a single source; the chemical composition averaged across the batches of the ingredient used in the two studies, was: DM, 88.4%; CP, 23.8%; crude fat, 2.4%; NDF, 37.1%; ADF, 11.6%; ash, 2.7%. A total of 1,020 (10 replicates) and 2,380 (14 replicates) barrows and gilts were used in Study 1 and 2, respectively, housed in groups of 34 (single-sex in Study 1; mixed-sex in Study 2).

The study was carried out at a commercial research facility that is equipped to collect data on growth performance and feed intake under typical commercial conditions. The start and end body weights were 6.6 ± 0.54 and 6.4 ± 0.56 kilograms (weaning) and 127.1 ± 1.71 and 133.3 ± 1.62 kilograms, for Study 1 and 2, respectively. An eight-phase dietary program was used. The corn-soybean meal-based control diet containing 0% CGM was used as the reference diet to compare with the CGM diets to estimate productive energy.

All diets were formulated to be isocaloric relative to the corn-soybean meal reference diet by using supplemental fat, and to a constant digestible lysine to energy ratio within each phase, and to meet or exceed nutrient requirements proposed by the National Research Council (2012). Caloric efficiency was calculated for each dietary treatment using the feed conversion rate.

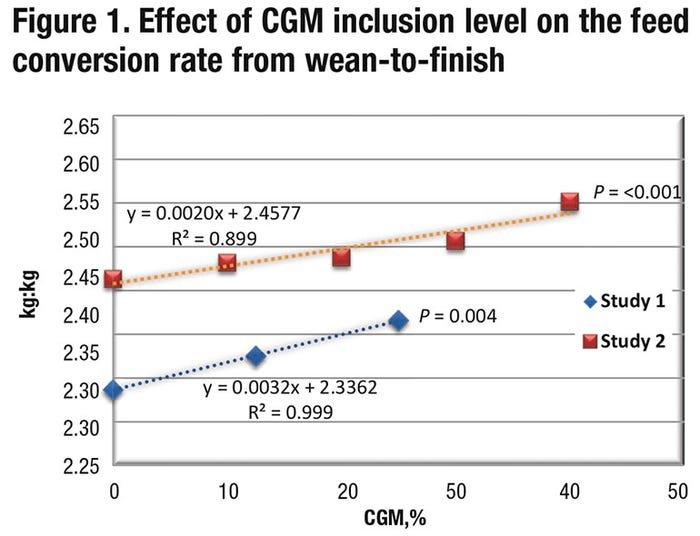

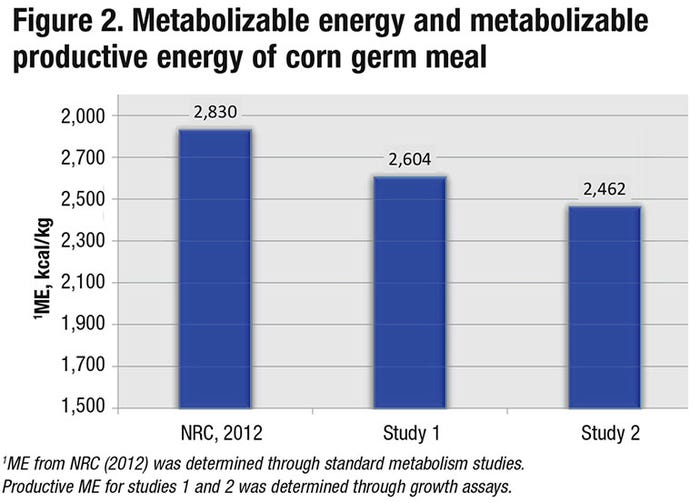

For Study 1, the CGM ME value used to formulate diets — based on published values and previously unpublished research — was 3,037 kilocalories per kilogram. In this study, increasing CGM level resulted in a linear increase (P = 0.004) in feed conversion rate [2.34, 2.38, and 2.42 kilograms per kilogram for 0, 12.5, and 25.0% CGM diets, respectively; SEM 0.023] (refer to Figure 1) that gave an estimate of productive ME for CGM of 2,604 kilocalories per kilogram (average of values for the two CGM inclusion levels).

For Study 2, the ME value used for CGM was of 2,681 kilocalories per kilogram, which was obtained by adjusting the previous estimate, determined in Study 1, for the chemical composition of the batch of CGM used in Study 2. In Study 2, increasing CGM inclusion level resulted in a linear increase (refer to Figure 1) in feed conversion rate (2.46, 2.48, 2.49, 2.50, and 2.55 kilograms per kilogram for 0, 10%, 20%, 30% and 40% CGM diets, respectively).

The estimate of productive ME from this study was 2,462 kilocalories per kilogram (average of values of the four CGM inclusion levels), which is lower (142 kilocalories; 5.4%) than the estimate of productive ME from Study 1.

The complete results are shown in Figure 2.

There is no obvious explanation for the difference in productive ME estimates between these studies. It could be related to errors and/or variation associated with the chemical composition analyses of the ingredients that were used to adjust ME values in diet formulation, as well as variation between the studies in factors such as season of the year in which the study was carried out, and the health status of the animals.

However, the slope of the change in caloric efficiency with increasing CGM level was numerically lower for Study 2 than Study 1 [10.44 and 6.61 kilocalories per percent of CGM for Study 1 and 2 respectively; Figure 1]. This indicates that the adjusted ME value of CGM (2,681 kilocalories per kilogram) used to formulate diets in the Study 2 was more accurate compared to the value used in Study 1.

In conclusion, there is considerable variation between literature estimates of the energy content of CGM, as well as between estimates of productive energy content from growth experiments carried out by the investigators. These differences could be due to variation in composition among CGM sources and batches, as well as differences between energy determination methods. Further research is needed to validate and/or adjust current energy values for CGM, as well as to establish the optimum methodology for carrying out productive energy determinations.

Researchers: Mike Ellis and Jorge Estrada, University of Illinois; Omarh Mendoza, Aaron Gaines and Caleb Shull, The Maschhoffs. For more information, contact Ellis, University of Illinois, at 217-333-6455 or [email protected].

You May Also Like