Current floor space allowances for finishing hogs are based on research that is 10 to 20 years old, when hogs were marketed at around 250 pounds. Recent multi-university research aimed to determine if today’s larger finished hogs require more floor space.

Are you giving your finishing hogs enough room?

Current floor space allowances are based on research that was done 10 to 20 years ago, from a time when market hogs were loaded for the processing plant when they reached a body weight of no more than 250 pounds. According to USDA, average slaughter weight for market hogs was 283 pounds in 2015, and often reaches the 300-pound level.

This increase in body weight has raised some concern that the allowance of floor space per animal is being challenged. A five-university collaborative effort undertook two separate studies to determine if larger animals are creating a negative impact on hog production.

Principle investigator was Lee Johnston, University of Minnesota, and co-principle investigators were Dale Rozeboom, Michigan State University; Bob Goodband, Kansas State University; Steve Moeller, Ohio State University; Marcia Shannon, University of Missouri; and Sarah Schieck, University of Minnesota Extension.

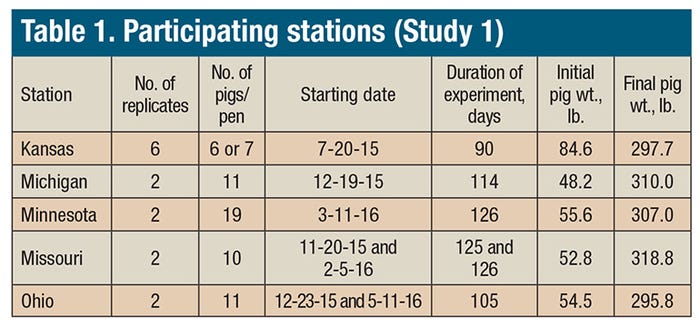

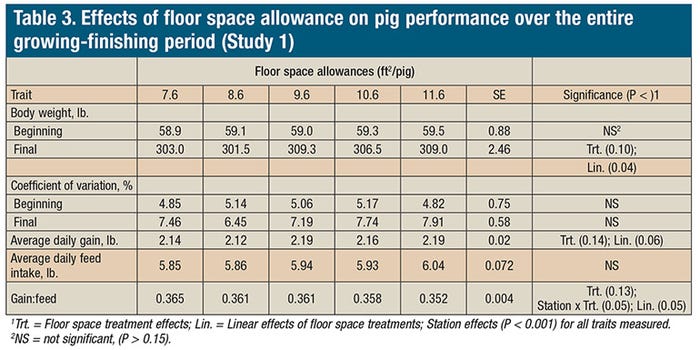

Study 1 was conducted at five research stations throughout the Upper Midwest region. Evaluated were the growth performance and welfare of pigs weighing between 60 and 300 pounds that were provided 7.6, 8.6, 9.6, 10.6 or 11.6 feet2 per pig of floor space.

Floor space treatments were imposed from initiation of the study until average weight of pigs in the pen reached 300 pounds. Floor space treatments were achieved by adjusting pen size for a constant group size across all treatments. Group size varied across participating stations but was constant across treatments within a replicate at each station.

Standard management protocols observed at each participating station were followed throughout this experiment. Pigs had ad libitum access to dry feed and water throughout the entire experiment. Feeding program (diet formulations, number of phases, phase breaks, etc.) was determined by each station and was standardized across floor space treatments with the stipulation that nutrient requirements described by National Research Council were satisfied. There was no “topping” of pens before the pen average body weight reached 300 pounds. The experiment ended when the average body weight of pigs in a pen reached 300 pounds. If a pig died or was removed for welfare reasons, pen size was adjusted to maintain the appropriate floor space allowance.

Pigs were weighed individually and feed disappearance measured on a pen basis every two weeks throughout the experiment. From these data, average daily gain, average daily feed intake (pen basis) and gain to feed ratio (pen basis) were calculated.

Neither daily weight gain (range = 2.12 to 2.19 pounds), daily feed intake (range = 5.85 to 6.04 pounds) nor gain:feed (range = 0.352 to 0.365) were influenced by the floor space allowances studied.

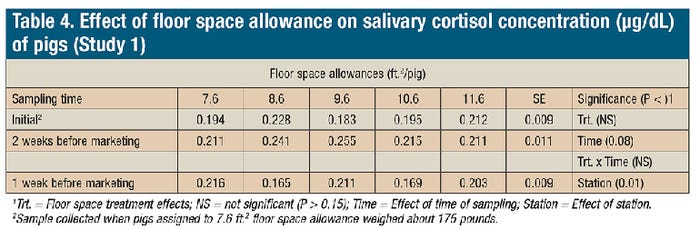

By suspending cotton ropes in each pen, saliva samples were collected on three separate days throughout the trial: when pen weight averaged about 175 pounds, two weeks prior to harvest and the week of harvest. After pigs chewed on the ropes, saliva was harvested and frozen for subsequent analysis. Saliva samples were analyzed for cortisol concentration.

Each station provided data from at least two replications for each treatment (Kansas provided six replications of each treatment).

Salivary cortisol concentrations (a measure of chronic stress in pigs) and lesion scores were not affected by floor space allowances. Based on previous prediction equations of Gonyou et al. (2006), it was predicted pigs would not feel the negative effects of crowding until pigs reached 210 pounds of body weight. About 62% of the total weight gain in Study 1 was under conditions that were not crowded. This period of early growth in uncrowded conditions likely masked any negative effects of crowding that might have been present at the end of the growing-finishing period.

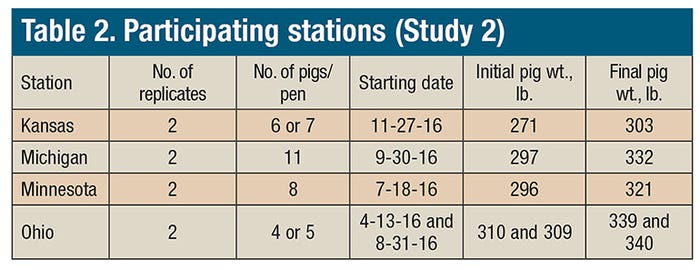

For this reason, a second study was undertaken at four research stations to focus on growth performance of pigs weighing about 300 pounds. Pigs weighing about 293 pounds were assigned to pens that provided 7.6, 8.6, 9.6, 10.6, or 11.6 feet2 per pig of floor space. After a two-week growth period, the study was terminated.

Increasing floor space significantly increased average daily gain (1.89, 2.09, 2.09, 2.43 and 2.34 pounds per day) and average daily feed intake (6.68, 7.19, 7.10, 7.70 and 7.17 pounds) in a linear manner as floor space allowance increased.

Results of Study 2 suggest that the optimal floor space allowance for pigs weighing about 300 pounds is 10.6 feet2 per pig.

Based on the results of the experiments conducted in this project, it appears that the equation of Gonyou et al. (2006) used to predict floor space allowances for growing-finishing pigs based on their body weight is still valid for pigs marketed at about 300 pounds. Under commercial conditions when pens are “topped,” there likely will be little if any depression of pig performance or welfare when using the Gonyou equation to determine floor space allowance.

Any surprises?

“I was surprised that we did not see any substantial negative effects of the very low floor space allowance (7.6 square feet per pig) on growth performance over the entire experiment,” Johnston says. “I thought that we would see some depression in performance due to the crowding at the lowest space allocation. Maybe pigs adapted to those crowded conditions because they ‘grew into’ the crowding situation as they got heavier, but that’s just some speculation.”

Though the findings from these studies seem to support the current industry practice on floor space allowance for finishing pigs, “I do not pretend that our study is the final word on this topic,” Johnston says.

Johnston acknowledges that floor space allowance figures for finishing pigs cannot be extrapolated to establish floor space allowances for sows in group housing operations. “Of course, there is a size difference, but there are also different dynamics among sows and different response criteria (reproductive traits) compared with finishing pigs,” he says. Yuzhi Li, Sam Baidoo and Johnston at the University of Minnesota have just completed a very large study that examined floor space allowances for gestating sows housed in electronic sow feeding pens.

This research project was funded by the Pork Checkoff.

About the Author(s)

You May Also Like